- This topic has 713 replies, 3 voices, and was last updated 6 years ago by yourguitarhero.

-

Brewers of STW

-

peterfileFree MemberPosted 9 years ago

How long was your beer sitting in primary fermentation? If you leave it too long it can lead to soapy flavours, but IME you’d have to leave it pretty long indeed.

What do you use to for cleaning and sterilizing your FV and bottles? I’m assuming you don’t let fairly liquid (or similar) anywhere near your kit or bottles?

PJM1974Free MemberPosted 9 years agoTwo weeks in primary fermentation, in keeping with the instructions.

No, I don’t use washing up liquid. I use the sterilization granules sold in Wilkinson’s and ensure that everything is sluiced out with water afterwards to try to avoid this.

peterfileFree MemberPosted 9 years agoCan you give a bit more detail about how you clean and sanitize? That would be the best thing to try changing first for two reasons: if it’s happening across all your brews regardless of yeast used etc, then it sounds like a process issue (ie sanitation) and secondly, it’s a cheap and easy thing to try differently.

I clean with a soak/scrub with oxy cleaner, then rinse repeatedly and then sanitize with Star San.

I wouldn’t be particularly comfortable using an all in one cleaner/sanitiser, particularly one that requires you to rinse with tap water after you’ve “sanitised”. I think bruclens is a chlorine based cleaner…perhaps it’s residue?

You could try another cleaner and a no rinse sanitiser (like Star San). Star San is great stuff and makes most brew sanitation a doddle.

davidrussellFree MemberPosted 9 years agohey guys, my first brew has been in the primary now for 11 days, so will be fermented out. it was dry hopped a week ago so should be coming along nicely. question is how long do you chill it down for if you use temp control? i’m going to bottle soon so i’m going to chill down to 6 degrees for a few days. actually looking forward to getting this one n the bottle and planning my next brew!

yourguitarheroFree MemberPosted 9 years agoBack to the low OGs

I don’t check the gravity after the mash. Mash temp is 66cHere is the recipe I used:

Ingredients

Amt

Name

Type

#

%/IBU

1.37 kg Wheat Malt, Ger (3.9 EBC) Grain

0.54 kg Pilsner (2 Row) Ger (3.9 EBC) Grain

9.68 g Hersbrucker [2.75 %] – Boil 60.0 min Hop

2.42 g Perle [8.00 %] – Boil 15.0 min Hop

2.42 g Spalter [4.50 %] – Boil 15.0 min Hop

0.4 pkg Weihenstephan Weizen (Wyeast Labs #3068) [124.21 ml] YeastGravity, Alcohol Content and Color

Est Original Gravity: 1.045 SG

Est Final Gravity: 1.011 SG

Estimated Alcohol by Vol: 4.5 %

Bitterness: 13.0 IBUs

Est Color: 7.2 EBCMeasured Original Gravity: 1.035 SG

Measured Final Gravity: 1.? SG

Actual Alcohol by Vol: ?Mash Profile

Mash Name: Single Infusion, Light Body, No Mash Out

Sparge Water: 7.38 l

Sparge Temperature: 75.6 CTotal Grain Weight: 1.91 kg

Grain Temperature: 22.2 C

Tun Temperature: 22.2 C

Mash PH: 5.20Mash Steps

Mash In Add 4.78 l of water at 72.6 C 65.6 C 75 min

Sparge: Fly sparge with 7.61 l water at 75.6 C

CaptainFlashheartFree MemberPosted 9 years agoContinuing my single hop exploration, my latest, repeating the same recipe and varying the hops, used Columbus.

Oh yes! Very much yes!

john_drummerFree MemberPosted 9 years agoI used to have some issues with phenols in my final beer, which gives that soapy/medicinal taste. I put it down to using powdered chlorine based cleaner (VWP) and some of the powder not being fully dissolved, getting into fine scratches in the fermenter.

so for cleaning I now use this stuff:

http://www.morleyhomebrewcentre.com/ucommerce/cleaning-sanitiser/pro-kleen-purple-beer-line-cleaner-5ltr/c-23/c-162/p-1206a capful of this in a washing up bowl sized volume of water is fine.

then rinse well with cold tap water and leave upside down to air dry.Starsan is good but you do still need to clean your post-boil equipment, especially the fermenter where the scum from the kreuzen head remains after it’s finished fermenting. I use a foam kitchen thing and make sure I don’t use the scourer side of the pad.

Also a good idea to add a crushed campden tablet to your brewing liquor (water) before the mash

WillHFull MemberPosted 9 years agodavidrussell – Member

hey guys, my first brew has been in the primary now for 11 days, so will be fermented out. it was dry hopped a week ago so should be coming along nicely. question is how long do you chill it down for if you use temp control? i’m going to bottle soon so i’m going to chill down to 6 degrees for a few days. actually looking forward to getting this one n the bottle and planning my next brew!Just a word of warning – fermentation might not have finished after 11 days (but then again it might). Best thing is to take a sample, measure the gravity. Do the same again 24hrs later. If there’s no change then it’s probably finished primary fermentation. Common advice is to take a third sample, and if you get three days in a row with no change in gravity then you’re done. Just because it’s been 11 days and it looks like it’s finished, doesn’t mean it has.

I tend to leave my beers in the FV for about three weeks, which seems to work for me. Some people swear by two weeks, some swear by four weeks, and pretty much everything in between. Like many things in brewing, there really is no right or wrong way to do things, but a spectrum of possibilities, and as long as you end up with good beer it doesn’t matter how you go about things. Like with chilling at the end of fermentation – some will tell you all the crap drops out and the beer will be clearer, others will tell you how they’ve tried with and without and it makes no difference. I suspect it won’t do it any harm if you give it a go. 48hrs should be plenty.

davidrussellFree MemberPosted 9 years agogood point, time to check the gravity and a wee cheeky taste!

How well would 25kg of malt store by the way? Its going to get expensive mail ordering 3kg ofgrain with a 6.95 delivery charge, so was thinking of going for a 25kg sack. The other option i might have is that i live in alloa and i think there is still a maltings here, so might be worth trying to buy direct!

john_drummerFree MemberPosted 9 years agoas long as you’ve got somewhere dry to store it, free from mice & rats, no problem. at a 2.5kg grain bill per “Massive” brew, you’ll only get max 10 brews out of it so if you’re anything like most brewers, it won’t haver time to go ‘off’

davidrussellFree MemberPosted 9 years agothanks j_d i smell a bulk buy coming on!

edit – the Crisp maltings group are on my doorstep!

davidrussellFree MemberPosted 9 years agoWell against better advice i just bottled my brew today, without taking 3 days of readings 🙂

Good news is the FG was 1.008, from an OG of 1.057. These were values taken at 20 degrees, although I’m not sure how the addition of the water after i took my first reading will have affected it – i assume the volume is greater as I took the OG before adding c. 1.5l to the wort so the ABV will be less than what i think should be 6.5%. Either way a pretty potent brew, although I’ll be amazed if those figures are bang on.

It also tastes really good. Lovely colour, malt character and a nice bitterness from the hops but not too much flavour or aroma. I’m sure this is to do with only dry hopping with 20g of hops but overall I’m really pleased. I think once it’s carbonated it should be great. Definitely a platform to improve upon.

Did have a bit of an issue with my syphon appearing to introduce bubbles in the wort (not sure what went on as it was underwater but bubbles were appearing in the syphon line) but i didn’t drag very much sediment through at all, it was a pretty clean brew. The trub was also very liquid and the gunk on the FV (Krausen?) was not difficult to clean off at all, compared to some of the brews I’ve don’t where you almost have to pressure wash it off…

I got 14 500ml bottles out of it, so 7l bottled which i think is good. I had nearly 1/2 a litre left over from bottling which was my hydrometer sample and the dregs from my bottling FV (see below – it became my first taster :)) and i had 1.75l of trub / yeast / wastage which sounded a lot but i don’t think i could have got more out of the FV without getting right into the sediment, so overall just shy of 10l into the FV.

Really quite happy so far, plans to get more malt and just do the same recipe again with a couple of tweaks to see how it compares!peterfileFree MemberPosted 9 years agoExcellent! Looks great!

1.008 sounds like it’s reached the end of the road, but i’d be really careful in future and just take a couple of readings. Getting it wrong can mean exploding bottles.

davidrussellFree MemberPosted 9 years ago:O

yeah good call. i think the wife would have a canary if the cupboard under the stairs was coated in beer! 🙂

So how does the refractometer work then PF? I’m going to be shopping for malt soon and its payday 😈

peterfileFree MemberPosted 9 years agoI bought this one for about £20, but it’s currently out of stock.

I calibrated mine with some wort that i’d taken a hydrometer reading from. It’s a great wee bit of kit and surprisingly accurate.

You just pull a tiny sample from the wort with a dropper. I then squirt it into a little dish which cools it an a few seconds. Then pick it back up with the dropper and put the sample onto the refractor window. All in all it takes about 15 seconds from taking the sample to having a reading.

I always take an OG and FG with the hydrometer too for certainty, however the refractometer means you can take as many gravity readings as you like on the fly. My accuracy for hitting target OG is now within 0.001. No more hoping where it will end up!

If there was one thing I’d recommend spending £15 on, it’s the water report and advice for water treatment from Murphy and Sons. Water forms the largest part of beer and I’ve noticed an incredible difference (particularly in IPAs/pale ales) since adjusting my water.

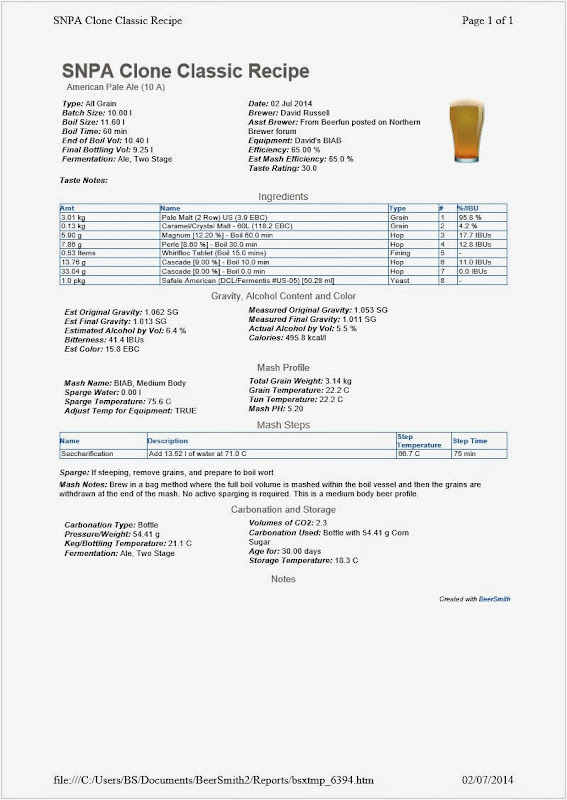

davidrussellFree MemberPosted 9 years agosuper excited for this weekends brew. I was looking for a recipe to use up some maris otter and my leftover citra, but i took a hankering for brewing the SNPA clone that Peterfile posted on page one. So i started looking around for the ingredients etc and happened across this post regarding the SNPA brewers gettin involved. So in short, the ingredients are on the way to make this at the weekend. Recipe below that i’ve scaled using my equipment profile, comments welcome. (OG looks a bit optimistic!) Can’t wait for this!

samuriFree MemberPosted 9 years agoSorry to bring this back to mere kit ales but my Coopers Dark Ale kit has turned out very nice indeed. It’s black as the ace of spades and very sticky. The head is much better than shown here, this is the second pint I drew after I’d managed to blow the seal on the barrel.

[url=https://flic.kr/p/obC3P1]2014-06-29 16.29.34[/url] by Jon Wyatt, on Flickr

davidrussellFree MemberPosted 9 years agoNothing wrong with kit beers Samuri, especially when they turn out looking like that 🙂

I brewed a festival ales porter at the tail end of last year and loaded it with the pellet hops that came with it. 7 months on and its got a great earthy character and jet black colour. Can’t have too many of them though 🙂

davidrussellFree MemberPosted 9 years agoSo i brewed up the SNPA clone yesterday and it’s in the FV now. Much more relaxed about brew day now, i don’t feel the need to watch over the mash like an expectant mother 🙂 Brew time was about 4 hours so there’s room for improvement there but I didn’t feel rushed or forget anything.

I took a lot of care this time to get an accurate mash volume by measuring out the water – i have a stainless 1litre jug and the markings were close enough to 1kg when i weighed it so i was confident the mash volume was correct to within a few ml, certainly not wildly out. I think my mash temps might be a bit low still, but it’s difficult to measure within the pot (I use PF’s trick of sticking it in the oven at 60ish degrees) so a thermometer with a probe might help, although realistically I’m not sure how you could adjust the mash temp quickly or accurately enough to make a difference. I think it’s probably a case of leaving it well alone.

I actually did better than my target OG for pre-boil – i hit 1.056 instead of 1.053, so if I’m right i think that means my mash efficiency is better than 65%? Either way I was reasonably chuffed so far.

I also just added the hops to the boil loose. I got a decent conical sieve from Sainsbury’s – solid stainless steel with holes punched in it – far better than the mesh design. It filtered all the gunk out and as said before it aerated the wort really well. I might use a hop bag for dry hopping but I think I’ll add hops loose to the boil now.

The issue came with post-boil OG / volume – it was miles over the target – 1.078! instead of 1.062 and when I put it in the fermenter it looked like 7.5L, so I topped up with tap water again (naughty) to hit the target OG of 1.062 spot on in the fv. I ran the risk of contaminating the brew again though so hopefully I’ll get away with it again.

However, I’m puzzled as to how I’m losing so much volume between the mash and post boil. I give the mashing bag a good squeeze after mashing, so I know I’ll be losing some volume there but that should be accounted for. I also googled the evaporation rates and I think I have the standard figure plumbed in, but I don’t think I could be boiling off 2.5l more than the figure. The only explanation I have is that beersmith calcs are off somewhere, either with the initial mash volume (although pre boil OG would be off surely?) or I’m losing too much to the grain.

I’m going to work out accurate volumes for my pot using a measuring stick and also test the boil off rate for my kit too, to try and get to the bottom of this. Happy enough with the process though and I’ve got 22.5kg of Maris otter pale malt in the brewshack to experiment with!peterfileFree MemberPosted 9 years agoHow much water are you mashing with David? I get 10 litres into the fermenter and that means starting with 15.5 litres of strike water.

The fact that you overshot on your OG suggests that your volumes were out (i.e you didn’t start with enough water), which is confirmed by the fact that you only got 7.5 into the FV.

mugsys_m8Full MemberPosted 9 years agoSo. An update from St Michel de St Geoirs brewery. The first batch where I mashed it at way too high a temperature actually turned out way better than expected. So much so that Mrs Mugsy prefers it to what we normally drink here: Affligem, Grimbergen etc (not strictly through pure choice).

The second brew went much better and is due to be bottled shortly.Had a bit of an epic bottling the first batch. I used a bottling bucket, but with just using the tap on the bucket I must have lost at least 1.5l on the floor. I have now bought a little bottler and a much better capper. So plan to bottle the 2nd batch tonight and get the 3rd batch brewing this week to be left whilst we go on holiday.

peterfileFree MemberPosted 9 years agoHa! Your bottling experience sounds very similar to mine! complete nightmare!

I too have the little bottler and it makes the whole process a breeze.

davidrussellFree MemberPosted 9 years ago+1 for little bottler. great wee bit of kit.

I started with 13.52L for the mash PF, per the beersmith instructions. If you plumb in the recipe above (its called SNPA clone classic recipe on beersmith)what volume of strike water does your beersmith suggest? or shoul i be ignoring that altogether?

sounds like its definitely a recipe scaling issue with the water then 🙂

peterfileFree MemberPosted 9 years agoI’ll check when I get home, but 13.5 is definitely a bit shy for a full volume mash.

Are you using the equipment profile for the massive brewery kit? It may be that that’s throwing your numbers off, given that your using a bigger pot and not sparging?

I’ve got a slightly tweaked equipment profile that takes into account i’m getting 10l into the FV and starting with a full volume mash and no sparge. I can upload it later if that would help?

davidrussellFree MemberPosted 9 years agoI am using a tweaked equipment profile so its based mostly on your previous profile, but upped the volumes to get 10l into the FV. If you could upload your current one i’ll download it and compare it to mine. It seemed to square with all the other values when i did the equipment wizard on beersmith, but clearly something is off.

Thanks again for your help, appreciate it.

davidrussellFree MemberPosted 9 years agoso here’s my equipment profile from BS – anyone spot anything odd?

peterfileFree MemberPosted 9 years agoDavid, I managed to read that before you took it down. Your batch volume needs to be 10 litres. I’d probably take your fermenter loss down to closer to 1 litre too.

That will give a total boil volume of between 13-13.5 litres.

I’ve just scaled a recipe with a grain bill of 2.6kg…shooting for 4.7%…and it’s telling me I need 15 litres of strike water. That sounds about right, it’s normally between 15-15.5 litres.

davidrussellFree MemberPosted 9 years agoHi Pf, quick on the draw 🙂

Yeah the equipment profile was way out, but i copied it via the cloud to beersmith on my desktop, so something went awry in between.

something weird going on though as my grain bill as posted above was 3.1x kg (i did tweak the colour very slightly manually) and a volume of 13 litres. What other settings do you select in Bs i.e. mash profile?

peterfileFree MemberPosted 9 years agoI always do a regular BIAB mash (ie no mash out or sparge). It’s the first option on the mash type list.

grumFree MemberPosted 9 years agoJust ploughed through this whole thread! Still quite a bit I don’t quite get but I guess it will become apparent when I get going.

I have a standard home brew kit I was bought as a gift a while ago and never ended up using. Being a bit of a nerd and liking to do things properly I think I’d like to try doing BIAB rather than starting with the kit.

Seeing as I’ve got the bits from the kit already is it still worth getting the Massive brewery thing (out of stock at the mo anyway)?

AFAICS what I need in addition to what I’ve got is something to boil in, a bag for the grain, and a wort chiller – is that right? Any recommendations for where to get these?

Thanks!

Garry_LagerFull MemberPosted 9 years agoA sheet of viole from a fabric shop makes the boiling bag – cost £2 plus MiL to stitch it into a bag shape with a sewing machine.

Wort chiller is just a length of copper pipe (10 m?) – £25 from B&Q for mine but prob cheaper elsewhere. Check you tube for instuction vid showing how it is wound around a cyclindrical template like a paint pot to make the coiled chiller. Not absolutely essential to chill the wort in this fashion, but I wouldn’t be without one personally.

Something to boil in is the most important question and depends on what heat source you’re working with and what batch size you’re planning. In simple terms all you need is a massive stock pot. How massive? Well a ‘standard’ brew bin is 25 L, so holds 23-24 L of wort to ferment. This will come from ca. 34 L of water after it is boiled – that’s a big old stock pot sat on the stove. Obv you can brew smaller to suit what you kitchenware you have to hand – also your hob size will need looking at to see if you can effectively (and safely) heat the volume of liquid you need.

I have a tea-urn boiler that sorts all this out – costs around £100 though.

grumFree MemberPosted 9 years agoThanks Garry. Bag shouldn’t be too hard to sort. Not sure if my DIY skills are up to making a wort chiller but I’ll look into it.

I was thinking of getting the big stock pot peterfile linked to on ebay way back in the thread. Not sure if it will work ok on my stove or not really without trying it. If I can make a wort chiller I could probably splash out on an electric boiler in suppose.

peterfileFree MemberPosted 9 years agoGrum…davidrussell made a rather impressive looking DIY chiller. Perhaps he could be of assistance?

davidrussellFree MemberPosted 9 years agoHey Grum,

Hope the wort chiller posts above make sense. My top tips if i was doing it again would be:

1. the crucial bit of the wort chiller is getting a nice curve without crimping the pipe to get the exit pipe running up the inside of the coil. if i was doing this again i’d make that bend using a pipe bender. I’d feed the pipe bender approx 2 feet onto the coil and make a near 90 degree bend, leaving the pipe bender in place (could be controversial doing this but i think it would stop the pipe crimping. I’d then feed my gas main over the now bent 2ft section after taking a check out of the bottom of the gas main. I’d then start winding the pipe round the gas main (or whatever else you have)working from the ground floor up. This would allow you to wind the coil around the exit pipe without having to worry about trying to squeeze it through the coil after making it. To be honst neither scenario is ideal as this is where you are most likely to bend the pipe. copper is surprisingly pliable until it starts to kink and then it creases very easily, so it was a tetchy moment doing the last section as i almost buggered it. Luckily some gentle work with pliers got it back to normal(almost, my OCD is still smarting 😉 )

2. If you can get a bit of gas main thats straight is really good to use, just about the perfect size for a 15-19l pot.

3. give the copper a good heat in the oven, it makes it easier to bend until it cools down, which it does rapidly – an essential property of a wort chiller 🙂

4. never straighten a section and then try to rebend it if at all possible, it almost never bends as well 2nd time round. If you follow point 1 above straighten the pipe as mich as you need to but be careful when bending it afterwards.

5. work out the height of your pot and how many coils you’ll need before the pipes exit the pot and get a good bend on them to get them out of harms way as much as possible. As others menioned up there if it leaks you are in trouble.

6. the wee mini hose i linked to in one of the posts is the best tenner i spent on my AG setup. does the job brilliantly and i got a free spray gun for my regular hose to boot 🙂

7. get your copper from a plumbers merchant and shop around – its probably a tenner cheaper than b and q in most cases. Also check the coil for damage before you take it home/start using it, if a small ding is there it will probably kink when you start bending it.

8. finally, unless its a really serious issue, don’t let OCD get the better of you and try to fix it. I did and wasted £16 worth of copper in doing so. In most cases the kink will not be serious enough to severely impair the flow so just let it be 🙂

Hopefully this helps, good luck if you try it.

Cheers

EDIT – crude visual representation if what i mean below. copper is coopper coloured coil, the grey bit is your pipe bender. The yellow thing is a cutout of the gas main and the black blob in the bottom lefthand corner is your cutout for the pipe to come through. The copper would be wound anti clockwise from the ground up.

Garry_LagerFull MemberPosted 9 years agoThink I’d made my wort chiller in the time it took you to type that post David 🙂

You’re right about being careful not to kink it though – need to make small adjustments when you bend the pipe up through the centre of the coils.grumFree MemberPosted 9 years agoThanks David, that’s really helpful – definitely going to give it a go. Hopefully soon – will let you know how I get on.

The topic ‘Brewers of STW’ is closed to new replies.