Forum Replies Created

-

The Bossnut is back! Calibre’s bargain bouncer goes 29

-

Mike_DFree MemberPosted 3 years ago

Don’t know if it’s exactly the same (and I’ve forgotten the RAL code) but it’s certainly in the same ballpark. Tempted to use some of the left-over paint to do my ancient Cannondale hack bike which is now about 40% bare metal 🙂

Mike_DFree MemberPosted 3 years agoYeah, the blue ones do seem to be particularly bad for it, although I’ve seen a fair few “white” ones that are down to primer over large areas (particularly the roof above the windscreen). It’s one of the things that makes me nervous when people just glue solar panels to the roof – they’re probably extremely well stuck to the paint, but the paint isn’t necessarily very well stuck to the van…

Mike_DFree MemberPosted 3 years agoTowing is going to be easier than car-topping. If it’s on a combi trailer you’re likely (exact boat choice and launch site permitting) to be able to launch/recover single-handed, and if it’s on your drive on a trailer it’s always ready to go. From experience, it needs to be as faff-free as possible or you’ll never go out.

Mike_DFree MemberPosted 3 years agoFoam rollers (and foam “brushes” for the fiddly bits). There’s a knack to it but you can get a good finish (and can be done shiny if you like).

Mike_DFree MemberPosted 3 years agoBuilt up a bike for eldest daughter, she laced the wheels and did them with a repeating pattern of coloured nipples. Oh, and alternating black and silver spokes 🙂

1Mike_DFree MemberPosted 3 years agoLightweight is good! But also time-consuming. Anyway, another update incoming!

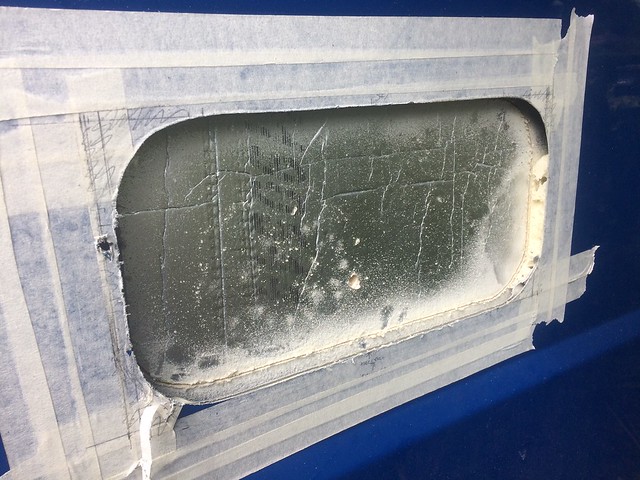

So the van was starting to look a little tired, not just because of the vandalism up-thread but also because Ducato paint is notoriously not the finest and was beginning to flake off in places. We looked briefly into resprays but the cost was fairly alarming. We’d always had a bit of a soft spot for satin/matte finishes on vans, so with the aid of a massive thread on one of the classic VW forums we painted it on the drive. Got rid of all the flaky bits and rubbed down:

Sanded back and primed some particularly bad spots:

And then set to with paint. We used satin finish Rustoleum Combicolour in a custom colour mix – Brewers decorating supplies will do any colour your want as long as it’s got a RAL code. Followed the instructions on the Club 80-90 Rustoleum thread (Google it, it’s super useful) regarding thinners and application and over the course of a long weekend got to here:

Which is a massive improvement. And also still nominally blue so we didn’t have to do any DVLA paperwork 🙂

Mike_DFree MemberPosted 3 years agoOh aye. I was referring to the space-inside difference but yes, a coachbuilt certainly has a bit more “road presence” 🙂 The low-profiles are a lot sleeker than traditional overcab coachbuilts, a lot more of them around now than there used to be.

Mike_DFree MemberPosted 3 years agoOoh, nice. Clever vans, those, you get a lot into not much length. The extra width of a coachbuilt makes a big difference.

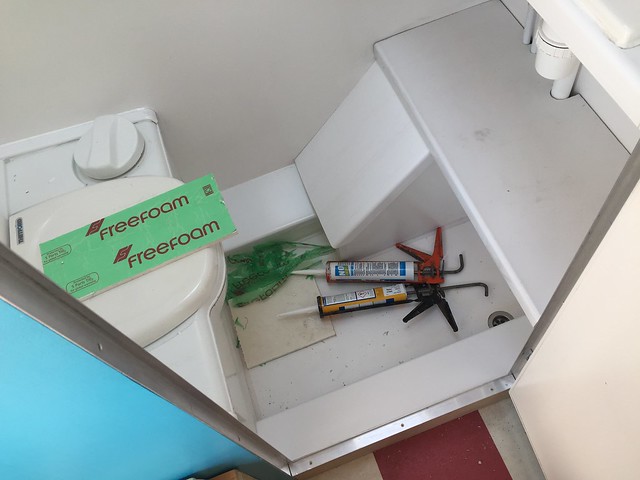

Mike_DFree MemberPosted 3 years agoSome more interior finishings off… The plastic shower tray in the bottom of the washroom cracked, and we’d pulled it up to fit the extra heater ducting, so we rebuilt the washroom floor using more PVC-faced plywood and corner joint strips. Some trial runs with offcuts showed that this would be suitably waterproof:

Some sections of PVC from the building plastics place to finish off:

Much better (this pic from before everything was siliconed up properly – did finally add the bottom threshold for the door, though…):

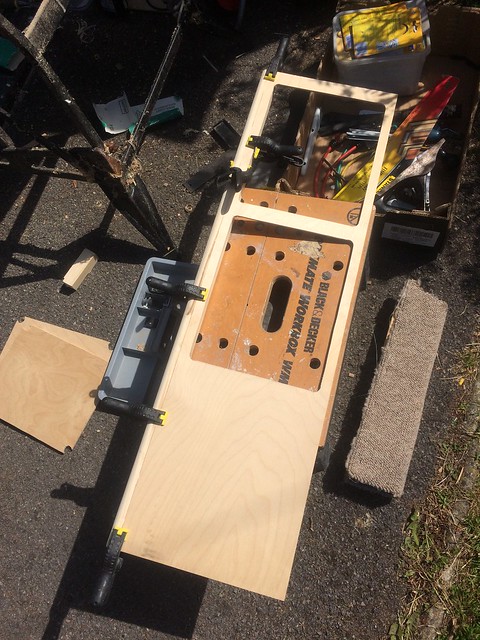

We also had an issue with the table, which looked great in its beech woodblockness but was really too heavy to comfortably lift in and out of its home behind the front seats. So made another one from 12mm ply, which by itself would be too flexible but with some strategically-placed extra pieces of ply underneath is plenty stiff (and about half the weight of the previous one):

The plain look was a bit dull so we covered it with some map-style paper and a couple of coats of varnish, which has proved hard-wearing so far:

After all of which the interior was looking something close to finished, bar a few unpainted bits. Er, and some bits you can’t see from this angle. Anyway:

Meanwhile outside the demands of growing children and the resulting phone/tablet charging meant that a bit of a power boost was required, so found space for a third solar panel:

…shortly before taking all of them off again, plus a load of the exterior plastics:

Because it was time to do something about the paint…

Mike_DFree MemberPosted 3 years agoI don’t have an up-to-date unladen weight, which is something that needs doing. We’re under 3.5t laden (people, food, clothes, bikes, couple of paddleboards, camping kit etc) but it’s close. We took a canoe on a roof rack to France recently and that was enough to make a couple of the autoroute toll booths reject our tag, so I suspect we’d managed to drift over on a couple of occasions (some of them have weigh-in-motion systems on the drive-through lanes). The van itself is a Maxi with heavy-duty springs and big brakes, we could replate it to over 4t just with paperwork, but it’s easier to travel with less water in the tank and leave stuff we don’t need at home. It’s built very light, everything that looks solid and thick is hollow. I should probably also take the towbar off, which we never use and I suspect is about 30kg.

The worrying ones are all the recycled pallet wood/solid oak worktops/cast iron stove jobs…

Mike_DFree MemberPosted 3 years agoSome other odds and ends. This bit must actually pre-date the skiing – we were concerned about the underslung (and uninsulated) water tanks freezing (although it was Easter, so not crazy cold in resort) so arranged an auxiliary tank inside the van. There was a handy space under the sink (usually full of cereal boxes):

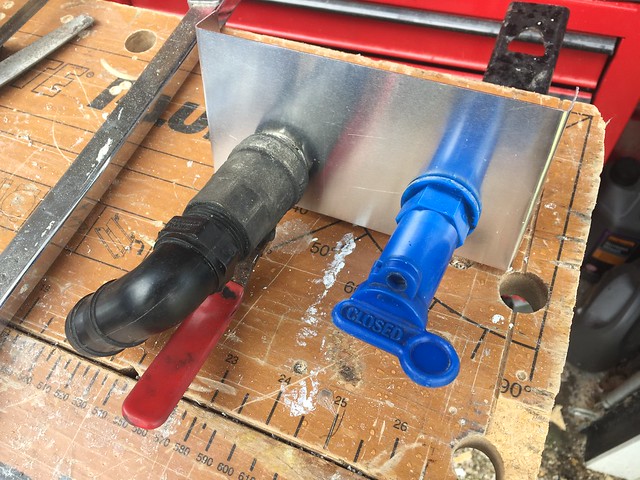

Got a 20l container and a tap, and arranged some new pipework under the shelf (which is where the pipe from the tank underneath comes in and where the pump lives). We now have a stoptap on the main tank feed, a Y piece to a second stoptap and a short length of hose with a threaded fitting to attach to the container under the sink. So if we’re likely to be somewhere very cold, we can fill the container (by lifting it out and carrying it to a tap), turn off the main tank, connect the hose and turn it on. Worked well, just had to fill it more often.

As an aside, when I was messing with pipework this little clump of plastic swarf (which must have come from the tank) fell out, which explained why the water flow from the sink tap had been a bit erratic – the swarf must have been constantly bouncing off the filter in the pump. All much better with it out:

Waste water was dealt with by leaving the drain tap open with a bucket under it. Oh wait, we couldn’t fit a bucket under it and the tap wasn’t very accessible so rebuilt all that too. Wanted to bring the drain taps out to the sill rather than having to rummage for a tap at arm’s length, so made up a bracket from folded aluminium:

Offer up the taps (lever valve for the waster which gets emptied often, plastic tap for the fresh which gets emptied rarely (or rather, it often empties but via the taps inside…)):

Drilled (and cleaned up and painted the edges of) two small holes in the sill flange, Sikaflexed and (stainless) bolted the bracket on:

And taps. Much better – easily accessible and they don’t stick out from the side of the van:

We knew we’d be parked on Tarmac in resort, so finally got around to fitting the awning leg brackets that came with the awning in 2015 and had been lurking in a box of bits ever since. Holes, rivnuts, Sikaflex, stainless bolts, bosh:

What else? Oh yes, heat. We have a heater, but there was only one outlet. We had a grand plan to use the boot space as a drying room – there’s a mushroom vent in the top, so we just needed to get some heat in at the bottom. So got a diverter valve for the heater outlet and a load of trunking to split off another outlet:

(Also seen here the actual proper heater outlet that got made, rather than the hot air just coming straight out of the end of the heater into the van:)

Heater duct through the bottom corner of the washroom, which meant pulling out the plastic shower tray (which had cracked anyway, so no great loss). Put another T in here so there’s also an outlet in the washroom itself:

And finally routed to an outlet in the boot space:

(Low-wattage tube heater also fitted in case we found ourselves on a hook-up). Then just had to pop a hanging rail in and:

Worked pretty well, slightly to my surprise. Then again, it’s a 2kW heater so maybe not that surprising. And yes, we did travel with a sealant gun, you never know when you might need one…

Mike_DFree MemberPosted 3 years agoA lot of people pass through on foot, I can’t be sure it was someone in the street. Like I say, it wasn’t parked outside anyone’s house – there’s a stretch at one end with a tall hedgerow that always has half a dozen cars parked along it, it was there. It all worked out, as the paintwork was becoming increasingly badgered anyway, of which more later 🙂

Mike_DFree MemberPosted 3 years agoCruise control was fun. It’s a retrofit kit – later models of van either have it already fitted, or adding is a case of adding the control stalk and turning the feature on in the ECU. Ours was a bit more involved. Needed access to the dashboard fuse box and steering column:

There’s a little control box to hide away somewhere – this little space near the fusebox did nicely. Needs wiring in to power and a vehicle speed signal (which you can pick up from the loom nearby):

It also needs to talk to the pedals. There are extra wires to connect to the brake light switch behind the pedal, and to the clutch, so that if you press either of those the cruise disengages. And so it can actually control the speed, there’s a piggyback harness that sits between the throttle position potentiometer and the ECU so that it can make the ECU think that the accelerator pedal is in positions it isn’t and you can take your foot of it. I’d hoped this would just involve pulling a plug, adding the harness and putting the plug back, but the top of the accelerator pedal assembly is way up behind the dash and no amount of James Herriot-style rummaging was going to do it. So I took it out:

Plugged in, put it back:

Then there was just the control stalk to fit and connect. There’s a handy space on the steering column shroud below the indicator stalk, so drilled a hole and put it there:

End result is, I think, quite tidy – almost factory:

Best of all, it works really well – absolute boon if driving, for example, the length of France. Recommended.

Mike_DFree MemberPosted 3 years agoHello! Long time no post. Some updates – going back a little way here but we’ll catch up. I think we’d just come back from the Western Isles. Had builders in so parked the van down the road for a bit, which someone clearly didn’t like:

Somewhat of an arse, especially having deliberately parked it not outside anyone’s actual house. Cleaned that up, then three weeks later:

Keyed for 6m along one side. Marvellous. Touched it in while hatching a plan, but not much happened for a while except for some maintenance jobs like sorting the connector to the cabin fan resistor pack that melted (they do that, if you have one of these vans and the fan only works on full speed, check this):

The following Easter we adapted the bike racks as ski racks:

And drove to the Alps:

Upon return progress picked up again a bit. The fridge wasn’t working too well in hotter conditions so added a vent:

Complete with a fan tucked inside in case it ever got _really_ warm:

And the fan broke again but this time it was the switch, which meant doing this:

Taking all of this off:

To access this:

And swap it for a new one:

And in the next instalment we dismantle the other half of the dashboard as part of Project Cruise Control:

Mike_DFree MemberPosted 5 years agoSTILL GOING!

A few random odds and ends. Finished boot threshold with alu angle, this would probably be better with the edge of the floor rebated so it sits flush but whatevs.

Made a couple of washroom shelves from uPVC cladding, the L-section stuff upside down to make a handy lip:

Moved the coat hooks:

Spent a bit of time finishing off the bottom edge of the speaker/amp/switch console thing. CAD:

3mm ply:

Another bit of ply to fill in:

Needs filler/sanding/paint, but not too shabby:

Mike_DFree MemberPosted 6 years agoI was always a sticks fan in the 80s, but wheels were gaining ground and seem to be ubiquitous now.

Mike_DFree MemberPosted 6 years agoBitten the bullet and booked an Easter apartment in Val Thorens, hopefully there’ll be some snow left. Was OK last year 🙂 Probably mix it up with board and skis depending on conditions/inclination. Kids aren’t doing lessons this time, hoping to get a couple of proper Big Days Out…

Mike_DFree MemberPosted 6 years agoI was a Kyosho fan (although had a Tamiya Fox for a bit). Optima, upgraded with belt drive, then a Turbo Optima Mid and a Lazer ZX. The Lazer was undoubtedly the fastest but actually a bit dull. The Mid was ace – geared for 4 minute races (crash and you lose, battery life was 4:20…) on an indoor track it was blindingly fast 🙂

Mike_DFree MemberPosted 6 years agoI’m a secondary school computing teacher. Provision in primary schools is, to be charitable, patchy. Provision in secondaries isn’t much better. There are a lot of ICT teachers who’ve been chucked in at the deep end with an all-new computing curriculum with no training or support. Some are keen and are training themselves up, others less so. Teachers with computer science or similar degrees thin on the ground. And in the state sector market forces don’t really apply to recruitment – just because a subject is short of teachers doesn’t mean that you’ll get paid any more.

So yes, it’s all a bit sketchy.

Mike_DFree MemberPosted 6 years agoDidn’t realise I’d provided any, but happy to unknowingly help 🙂

Mike_DFree MemberPosted 6 years agoI’m very much enjoying the space age teleporter look of that shower 🙂

Mike_DFree MemberPosted 6 years agoI think I missed all that 🙂 Still a member, didn’t go in there for months though.

Mike_DFree MemberPosted 6 years agoSomeone’s already plugged my van thread, so I won’t again 🙂 We went for a Propex heater to save mucking around with the fuel tank in the van. And it’s a bit cheaper.

Mike_DFree MemberPosted 7 years agoFor old times’ sake, cut yet another hole in the side of the van. Decided that the bottom bunk was a bit dark and dingy, so:

Yes, there’s a hole in the wrong place, yes, it got sealed up, yes, it’s hidden by the flange of the window, no, it doesn’t leak etc.

In a departure from the other windows, this one’s actually a Lewmar yacht window. Made up a little curtain for the inside which I don’t seem to have a picture of.

Also sorted out the overhead lockers a bit, with bungees inside to stop stuff tipping out when you open a door and mini gas struts so you don’t have to balance the door on the top of your head:

And while fiddling with gas struts, decided to split the top bunk bed base into sections so we can move the whole thing out of the way and give the kids a bit more headroom if they want to sit and play games/read/whatever:

Few more bits to come 🙂

Mike_DFree MemberPosted 7 years agoAh poop, how did that happen? Pfft.

Yes, they do tend to jump out – bikes are strapped down for transit, it did 2,000 miles up to Scotland and around the Hebrides without an issue 🙂

Mike_DFree MemberPosted 7 years agoAnd next, an impressive milestone – ripping out a load of perfectly good stuff that we’d already done and doing it again, only different! Actually not the first bit that’s been done twice (one of the rooflights has been in and out more times than the hokey cokey) but one of the biggest…

We had an issue with the boot space, in that the lower pair of bikes sat on the boot floor, blocking access to the under-bunk space and ending up with loads of stuff stacked against/wedged in amongst. This was inconvenient. Remember the rather lovely shelf I spent ages on? Out it came, and in went some lengths of shelf track that I had lurking:

You can probably see where this is going – add brackets, pad appropriately, hang bicycle off them:

And in the lower position, two up:

Doing it this way means (as is hopefully clear from the picture) that the bottom of the boot is completely clear, so long things like chairs and inflataple SUPs (which are the new things that we have to accommodate, but they’re a bit more compact that the inflatable kayaks that we used to carry, so that’s a win of sorts) can be packed lengthways under the bunk.

Keen-eyed observers will note a handy-looking space over on the right. To capitalise on that I embarked on making a suitable unit:

But before completing that, we finally got around to putting down flooring on the, um, floor. GLUE:

FLOOR:

Tidy. Then I could finish the shelvy thing (recycling some bits of the old shelf in the process):

#

#And without all the clamps once the glue had set:

Ending up with this:

Just in time to experimentally load up ready for Mayhem:

Worked fine with one bike (as you’d hope, really). Finished off the threshold with a length of alu angle:

You may notice a New Hole – there was a space behind a wheelarch that was accessed from the side, which wasn’t that handy, so it now isn’t:

And clearly post-loading. Not quite as terrible as it used to be with that quantity of stuff in it:

Other dull-ish stuff: Finally filled in the previous gap at the bottom of the kitchen drawers with, imaginatively enough, another drawer. Although it’s a big one, because (a) more useful for pans and stuff and (b) one less drawer to make 🙂

Nearly finished:

Finished, apart from a handle:

Spectacular dullness: Made a bin. Or, more accurately, a housing for an Ikea plastic bin:

You’ve all seen this technique, but here it is again just because:

And with a hinged lid (prototype, better to come):

1Mike_DFree MemberPosted 7 years ago

1Mike_DFree MemberPosted 7 years agoAnd next, an impressive milestone – ripping out a load of perfectly good stuff that we’d already done and doing it again, only different! Actually not the first bit that’s been done twice (one of the rooflights has been in and out more times than the hokey cokey) but one of the biggest…

We had an issue with the boot space, in that the lower pair of bikes sat on the boot floor, blocking access to the under-bunk space and ending up with loads of stuff stacked against/wedged in amongst. This was inconvenient. Remember the rather lovely shelf I spent ages on? Out it came, and in went some lengths of shelf track that I had lurking:

You can probably see where this is going – add brackets, pad appropriately, hang bicycle off them:

And in the lower position, two up:

Doing it this way means (as is hopefully clear from the picture) that the bottom of the boot is completely clear, so long things like chairs and inflataple SUPs (which are the new things that we have to accommodate, but they’re a bit more compact that the inflatable kayaks that we used to carry, so that’s a win of sorts) can be packed lengthways under the bunk.

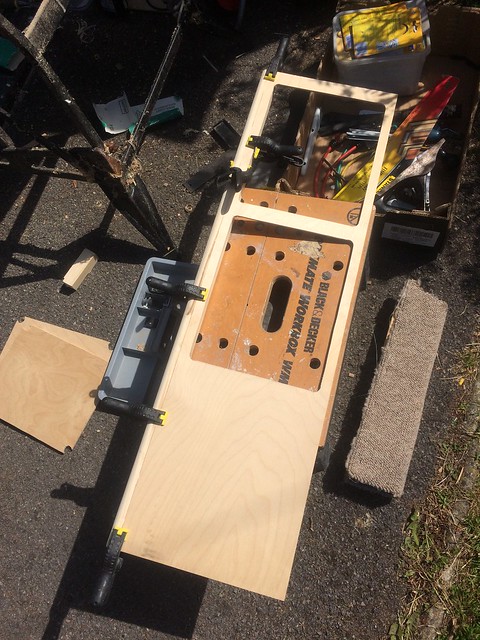

Keen-eyed observers will note a handy-looking space over on the right. To capitalise on that I embarked on making a suitable unit:

But before completing that, we finally got around to putting down flooring on the, um, floor. GLUE:

FLOOR:

Tidy. Then I could finish the shelvy thing (recycling some bits of the old shelf in the process):

#

#And without all the clamps once the glue had set:

Ending up with this:

Just in time to experimentally load up ready for Mayhem:

Worked fine with one bike (as you’d hope, really). Finished off the threshold with a length of alu angle:

You may notice a New Hole – there was a space behind a wheelarch that was accessed from the side, which wasn’t that handy, so it now isn’t:

And clearly post-loading. Not quite as terrible as it used to be with that quantity of stuff in it:

Other dull-ish stuff: Finally filled in the previous gap at the bottom of the kitchen drawers with, imaginatively enough, another drawer. Although it’s a big one, because (a) more useful for pans and stuff and (b) one less drawer to make 🙂

Nearly finished:

Finished, apart from a handle:

Spectacular dullness: Made a bin. Or, more accurately, a housing for an Ikea plastic bin:

You’ve all seen this technique, but here it is again just because:

And with a hinged lid (prototype, better to come):

Mike_DFree MemberPosted 7 years ago

Mike_DFree MemberPosted 7 years agoHonestly, no updates for months and then three in 24 hours. I spoil you, I really do 🙂

Ages ago I was boxing in the rear seats. Made the end panel to cover the heater:

It’s on magnets so it can easily be popped off for access if necessary:

All put back together it looks like this, which is rather neater than before:

Bunged another USB socket in the top for on-the-go tablet charging:

Up until this point the storage under the fridge has just been open shelves. An actual door would be a bit obstructive (has to open into the aisle), we thought about drawers but they’re a faff to make. And then had this idea – make a frame:

Persuade a handy parent to get busy with some canvas, zips and a sewing machine and presto:

When parked up, unzip, roll it up and secure with magnets thusly:

And another “mend broken thing” job – replaced the increasingly-battered passenger mirror housing, that had definitely been bounced off a few too many hedges. Again, right old faff to take apart, especially as a previous owner had at some point stuck it all together wit PU goop:

but much tidier when done:

They’re not original Fiat housings, pattern ones off eBay, but for £12 for both sides I’m not complaining 🙂

Also replaced the centre roller on the sliding door because it wasn’t running very smoothly. Can’t think why:

And discovered the frankly astonishing bumper-restoring properties of linseed oil, which I found a bottle of in the garage:

I also replaced the broken radio aerial, but I didn’t take any pictures of that on the grounds of extreme dullness 🙂

Mike_DFree MemberPosted 7 years agoMOAR.

Picking up from the most recent instalment, here’s some more switch panel. One of the little cubbyholes is intentionally phone-sized, so I put a USB socket in there to charge same:

Popped a speaker into one end:

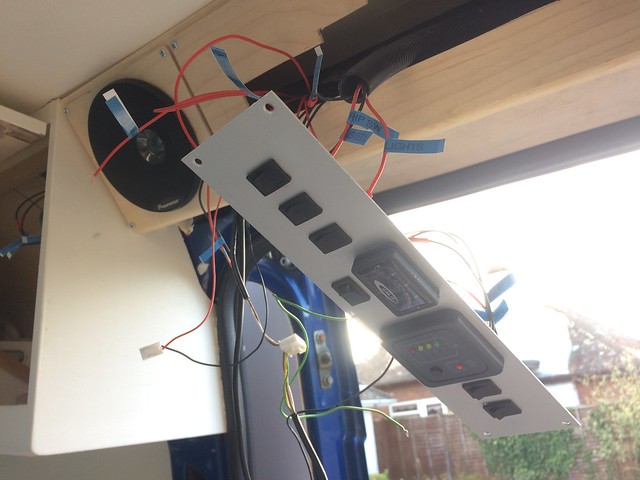

Connected up eleventy bazillion wires to the panel:

And screwed it into place:

But from where is the music coming, I hear you cry? MAGIC. Actually, merely sufficiently-advanced technology. Hidden inside the panel there’s a 12V-to-USB gizmo powering a Bluetooth audio receiver connected to the amplifier, so we can stream music from phones or whatever:

Mount the amp, panel to finish the front of the storage cubbies, other speaker, DONE:

(apart from filler and paint, obvs).

In other news, various maintenance jobs have forced themselves upon us. The wipers have been iffy for ages because the motor’s been gradually dying. Buying a motor turned out to be only slightly cheaper than getting a motor with new linkages attached, and I suspected that all the bushings were pretty weary, so got this:

which turned out to be most entertaining to replace, necessitating the removal of all this lot:

and leaving the van looking like this:

Still, got there in the end, all works. I don’t recommend removing and refitting a Ducato bonnet singlehandedly if you can possibly avoid it 🙂

More soon!

Mike_DFree MemberPosted 7 years agoSo, er, yeah, bit behind on the updates – this lot coming up was February half term…

Next step was an overhead unit above the sliding door to contain the switch panel, amp, a couple of speakers and a wee bit of storage. There are a few constraints here – it has to fit all that stuff (duh) but also not be too obtrusive – if it sticks out into the van too far then we’ll bang our heads on it when we get in. Which would be bad. Always keen to make life difficult, I went for an angled face, as seen in this Mark 1 former:

Seemed to work, so added another one:

Here’s a first pass at the main structure:

The ply formers are attached to the van and the ends of the unit will be supported by the kitchen at one end and the bulkhead at the other. Added more framing:

…and took out all the old junk, leaving lots of dangly wires. Lots of them got pulled into the locker over the kitchen, to which I’ve moved the left-hand fusebox and earth point for convenience:

Considerable amounts of untangling, tracing, trying to remember what goes where and labelling later, it’s looking a bit tidier:

The green wire is the feed from the batteries (there’s another (bigger) fuse at the other end), a bunch of lights and things are fed from this fusebox. There’s another identical one under the seats on the other side of the van which runs a load of other stuff. All the returns go to the metal connection block, which is just screwed to the bodywork with the paint sanded off underneath.

Current state of play:

There are (removable for maintenance) ply panels to go on the front of this – from left to right they’ll be speaker, switches, amp, cubby hole (with USB sockets in the side for phones), second cubby hole, speaker. Getting that lot all lined up will be entertaining.

In other news, I’ve made a start at boxing in the base of the rear seats. Now reasonably well practised at routing the corners off bits of timber:

Incorporated into the structure is an additional support for the fold-out bed flap, that’s been a bit saggy across the seat frames. This ought to sort it:

Sits neatly between the seat bases when they’re in place, which has the added benefit of making it significantly harder for children to drop pens/tiny toys/crisps down between the seats…

Hacked out a piece of 4mm ply to offer up:

Slightly tediously we need access under the front edge of the seat bases for the handwheel bolts that hold them down, which meant cutting this bit out:

although that’s also useful as a handle to detach the panel with – it’ll be held on with magnets eventually. Given that the batteries, mains charger, solar controller, heater, split charge relay, fuseboxes etc are all under the seats, access is definitely required.

Having done the same for the other seat and made a start on the frame around the side, the rear seats currently look like this:

which is quite a lot neater than before. Onwards!

Mike_DFree MemberPosted 7 years agoIt’s nearly finished, I should probably do an update 😉 Mechanical problems over the last four years (other than usual wear and tear): Breakdown in France caused by water ingress to ECU wiring (additional sealing and drainage added subsequently). Front brake calipers seized (due to too much time spent standing and not moving, most likely). Wiper motor needed replacing. Rear door lock broke. I think that’s it 🙂