Forum Replies Created

-

Mintel predicts £1 billion new bike sales this year

-

jamiesiloFree MemberPosted 9 years ago

nope!

supply coming in at 230v. motor was not driving anything, just spinning with no belts on the drive pulley.

with a digital multimeter:

1st phase 225-230

2nd phase 240 ish

3rd phase 280v ishany phase to neutral 130 ish

dvatmark did say somewhere back at the start:

Its worth noting that a digital volt meter wont read correctly as the voltage waveform will not be sinusoidal. If you want to measure the true output voltage you’ll need a oscilloscope I’m afraid.

for what it’s worth cheeky. the plate in the inverter reads

“output: 3ph 220v 7A 50hz”

given it’s wired up to the delta configed motor, designed to run on 3ph 220v in delta, i can’t see where 380v comes into it.

the point is there is no neutral being used anywhere but in the supply to the drive. between the drive and the motor, there’s just 3 lines of 220v (ish) being wired accross 3 windings at 220v. why are you trying to see 380v somewhere?if it was in star and running on 380v 3phase supply, as it was at my neighbour’s house, we would of course see 220v from phase to neutral used accross each winding, as you say.

and thanks for the extra bit of patronising. remember AC volts on your meter. come on.

they all seem to creep up if i leave the voltmeter there. sure someone can explain that?

seems not that balanced accross the phases, normal-ish for running through an inverter from what i’ve read, but i’da thought with a digital drive they might get it more balanced than that?

jamiesiloFree MemberPosted 9 years agoso when measuring between phase and neutral at the output terminals, you suggest i measure from one output phase terminal, to the supply neutral?

when the output terminals are connected to the motor wired in delta, there’s no terminal serving as neutral, right?jamiesiloFree MemberPosted 9 years agonope cheeky i haven’t measured it, but i will.

trying to stay open minded and learn something.but i btw i can’t measure accross phase to neutral in delta cos there’s no neutral, right?

jamiesiloFree MemberPosted 9 years agocheeky,

i won’t get 380v letween L1 and L2 etc because this is a 220v output drive, designed to give 220v in delta.if i wired the motor in star the voltage would be too low, as you said earlier cos it’s only a 380v supply.

this is the case here. ok, maybe this isn’t what you think of as a dual voltage motor, but that is how this motor works and is intended to work

jamiesiloFree MemberPosted 9 years agoas i understand it:

when in star config. with a 380v supply, the motor is putting the 220v from each phase to neutral, across each winding.whereas in delta, with a 220v (3ph) supply, as is the case here, the motor is putting the 220v phase to phase accross each winding.

so if the motor’s only ever using 220v, what’s the point in giving it 380v? well it uses less current, and therefore less power, so is safer and cheaper.

right?

i think we all agree about that stuff essentially

but cheekyboy, i think that’s what’s commonly called a dual voltage motor, even though the voltage being used across the windings to drive the motor is 220v in both configurations.

this is where i learned it:

http://www.allaboutcircuits.com/textbook/alternating-current/chpt-10/three-phase-y-delta-configurations/jamiesiloFree MemberPosted 9 years agobut here, since i’m in france, we’re dealing with 3ph normally at 380v and domestic at 220v. fact

most of what you say in your last post we all know and agree with, but please explain some things for me:

What is dual voltage then?

Why do these motors have delta and star options?

jamiesiloFree MemberPosted 9 years agoit does have to do with different markets historically achly, so i’ve read.

3 ph in the states being 220v.people say winding configuration to describe star and delta, because in effect you are changing the winding configuration when you flip between the 2.

not sure sure about torque requirments but on this machine, and many other it is used for EXACTLY that purpose, as stated on name plate. it’s a dual voltage motor; you can change between star and delta winding configurations in order to be able to change between voltages.

but funkynick and tragically have already said all that. i just wanted to say it again.

i’ve got some good spades if you need onejamiesiloFree MemberPosted 9 years agothanks mc,

it only came with 2 heads, neither seems up to much.

i’ll get new ones from axminster/wherever as an when i need them. will be mostly saw and planer/thicknesser it get used for initiallyjamiesiloFree MemberPosted 9 years agomc, thanks for bothering to read the manual for me :oops:

so like this one then?

http://www.ebay.fr/itm/START-STOP-STATION-2-PUSH-BUTTON-REMOTE-STARTER-CONTROL-PB-STS-/271914921516?pt=LH_DefaultDomain_3&hash=item3f4f646e2cand yeh, so it is those terminals with their settings selected for correct functions. looks simpl enough

i’m using it for work, but only me using in my workshop in my house.

safety inspection not big in france too.jamiesiloFree MemberPosted 9 years agooh, and what kind of switch should/could i wire in?

the big red shut-of switches that a lot of machines have on them, they have some kind of current to them right? or are they just mechanical cutting live/neut connection?would be nice to have something chunky and obvious.

anyone post a link to something suitable?also, can anyone digest the circuit diagram better than me and tell me which of the control circuit terminals are for switching? is it just FOR (forward) for go and and RST (reset) to stop?

jamiesiloFree MemberPosted 9 years agoand stop being children! just try to put your points so celarly that there’s no room for misunderstanding.

anyway thanks everyone. i’ve learned a lot.

jimmerjamiesiloFree MemberPosted 9 years agowell looks like i’ve got it working!

setting Pd145: Auto torque compensation

factory setting 2%, moved it up to 4% and jobsagoodun.

probably put it up a bit more cos it still struggles with rip-sawing.intermediate voltage is still up a bit. form factory 15v. 24v i think.

speed is fine. just faster that i expected! old machine fro 1978 = quality but not super smooth!

anyway, all good. delta wiring on 220v seems to be fine as my understanding of it suggested it should be.

jamiesiloFree MemberPosted 9 years agothanks mc

yes did that for resetaye, i’ll triple check those things.

jamiesiloFree MemberPosted 9 years agodon’t think so. no add-ons.

is V/F a changeble thing? in constant mode does it just clunk on and ‘force’ the motor up to speed?

jamiesiloFree MemberPosted 9 years agomc

where do you see that pole and rpm settings are for info only. i can certainly change them and when running, the display shows the max rpm i entered.

for that matter, where did you find the manual to look at?i tried a factory reset and it didn’t seems to do it.

not woried about speed any more. it’s clearly going at the right speed.

funkynick: “To me it sounds like one of the inverter parameters isn’t set correctly, and that you are trying to run with too low a voltage for a given speed.”

it seems like that to me too, but still can’t figure it out.

i’ll go check current under load etcjamiesiloFree MemberPosted 9 years agook thanks fellas. good info.

i haven’t checked the windings and don’t know what meggering means.

i will you google it. unles you got a simple explanation how to do it?finally getting somewhere then. but motor still lacks power.

guess i’ll check those things then.jamiesiloFree MemberPosted 9 years agooh yeh, and it’s not drawing the current it should when it’s running.

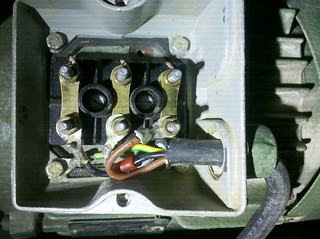

2.7a when up to speed and 2 pole settingjamiesiloFree MemberPosted 9 years agoright. think wiring is all correct, thanks tragic

now a new phenomenon

turning on machine with it’s own switch trips out the inverter. starting it with it’s switch already on, using the run and stop buttons on the inverter, starts ok.

error message when it trips says short circuit. can’t see how.changing intermediate voltage is the only setting which makes any difference at the moment. too much or too little and the motor won’t spin up. and it’s not affecting running torque, only start-up.

another thing, i can change how many pole motor it is in settings. research seems to suggest it’s a 2 pole due to 50 hz and 2840rpm. but it seems to behave exactly the same on either setting. is there a way to tell for sure without pulling the motor apart and looking at configurations of windings?

where do i get those emoticons? damn, there’s no :bangs-head-against-wall: one. aaaarrrggghhh. Noying!

the issue’s got to be with the inverter right? i bought the machine off my pal/neighbour who has 3 phase and it was working fine. and the wiring is apparently all good.

jamiesiloFree MemberPosted 9 years agothanks tragically1969. it’s actually running a combinaton machine ie saw, spindle moulder, planer/thicknesser. quite a small one though.

anyone know what the cos and symbol spec is above the weight on plate?

jamiesiloFree MemberPosted 9 years agoright, here we go

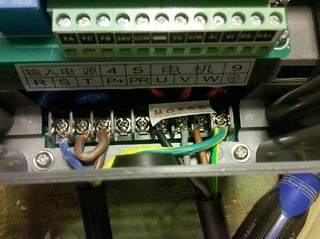

mc, yes single phase is over 2 of RST. dc voltage reading 300 odd.

plate suggests 220v = delta and will draw 5.9A current.

according to inverter display it was drawing about this til it got up to speed, then went down to 2.9 or thereaboutswith motor running 50 Hz shown on drive

funkynick. any clues there if it’s 2-pole or 4 pole?

jamiesiloFree MemberPosted 9 years agoright, so i can now get motor started while connected to the saw and runs up to speed, (though i must admit it seems very fast. rpm is set in inverter according to motor plate though)

i changed the intermediate voltage, ie the curve of the start-up (graph V against F) because in the manual it said wrong setting may result in under-torque of motor.

however it still seems lacking power/torque. and goes very fast as i said. i’d be worried about belts, and whole machine vibrates unsettlingly.

any more thoughts?

jamiesiloFree MemberPosted 9 years agomy next line of enquiry is setting ‘intermediate frequency/voltage’

these values used to define start-up curve. from readin manual again it sounds like i may need to increase one or the other to get more torque as it’s starting up. off to have a go…jamiesiloFree MemberPosted 9 years agonope it’s definately wired delta twonks. and as far as i understand, in this case delta is for 220v, star, or’Y’, is for 380v

just tried bridging the supply phase to the inverter over 2 of the RST terminals as described on ebay listing. made no difference whatsoever.

now i’m really stumped…

jamiesiloFree MemberPosted 9 years agothanks nick and again dvatcmark.

as i said, the motor is dual voltage, ie it’s designed to run ate 380v y-shape wiring, or 220v delta wiring. that’s why the converter i bought is 220v 3ph out, to go with the delta option, right?

i have of course used the motor plate to get the relevant ratings and entered them in the inverter settings: max voltage, frequency, speed rpm etc. pole number i couldn’t find, though am under the impression it’s usually 4, and the inverter factory setting is 4

jamiesiloFree MemberPosted 9 years agothat’s right, and this is a 380v in y wiring or22o in delta wiring 3phase motor, made for france. they did this so partly so they could sell to america withotu any parts changes

jamiesiloFree MemberPosted 9 years agothanks dvatmark,

yep all that’s checked and good. not getting hung up on volts, just that the voltage is the only setting that’s wrong that’s all. and aye, i don’t have the supply phase connected accross 2 of RST so that should sort it.

and i know the motor’s not knackered. it has to me my wiring or a setting, and seeing as i’ve sorted all the settings, it’s user error, as usual.

right, might go off and change that wiring…jamiesiloFree MemberPosted 9 years agook great, thanks a lot everyone.

yes i figured it was low volts to motor giving low torque.

still haven’t checked voltages cos i’m lurgied up but will do with an needle type meter if that worksdvatcmark, it’s this one :

http://www.ebay.co.uk/itm/251389853828

quite q lot of info there within the listing.

i notice it says “single phase connected to any 2 phases” under How to install this VFD

i’ve got live and neutral of supply just to one terminal each at R-S-T in diagram. should i try bridging 2 together from live? guess i should.jamiesiloFree MemberPosted 9 years agoah ok, i’ll check some things.

it’s wired in delta so there’s no neutralso at 220v 3 ph what should it be between phase and earth christian? any idea?

jamiesiloFree MemberPosted 9 years agothose saddle stones are beautiful! she won’t go for them sadly, tho i do need to work out how to keep rats out

thanks for the link mugsy, looks ideal.

i guess i’m a finishing joiner, or probably carpenter you’d say in England.

also interior fitter, specialist fabrications etc i have done. but right now i’m more or less a builder, not doing block-work, but stone and mortar, dry-lining and insulation, as well as all kinds of regular woodwork and finishing.

not that useful to you i guess tho?

where are you based?

i’m in Ardeche. biking’s great! : )jamiesiloFree MemberPosted 9 years agoah, cardboard tubes! just what i was after. no tseen them anywhere local though, and i’m in all the brico and trade places A LOT : )

any idea what they’re called mugsys?no drainage option i’m afraid. it’s all flat and clay.

but it does seem like massive overkill to me too.

however whne i was in the timber yard, the guy specked it for me before i could hardly say what i was after, completely standard in his eyes, and i could use some clients, so want it belt and braces…jamiesiloFree MemberPosted 9 years agofor sure on the shove-holer and trenching spade qwerty, if only i could find some in france, used to have some too.

a raft would sure be better but we’re both trying to avoid it.

i’l go with roughly what picton road was specking, which is what i had in mind anyways.cheers all

jamiesiloFree MemberPosted 9 years agobut thanks r the serious replies too.

if it were me i would hve just dumped it on some slabs, but it does need a floor of some sort.

i can’t see the clay being problematic but she assures me it’s a total quag mire in winter. so i can see a raft would be better. but we’re trying to avoid dumping loads of concrete which might be a pian in the arse some point in the future.so for those of you who do sound like you know what you’re talking about, does it mean piles are might ba fairly pointless?

i guess i’m oing to go and dig a hole and see just how deep and clay-y the clay isjamiesiloFree MemberPosted 9 years agoright thanks you bunch of smart arses : )

wish i’d never asked!jamiesiloFree MemberPosted 9 years agohow’s about a bump for this thread maximus?

project still going?jamiesiloFree MemberPosted 9 years agoAlistairMc, was waitin gfor someone to say that! but anyway, i’d want blutos, so that’s the point of the thread. it’s all about me obviously.

so what other fat sus fork options are there at the mo? saw somewhere talk of RST bringing one out with a straight steerer for eg. i’m fairly sure i’d go with a rockshox anyways but good to know

jamiesiloFree MemberPosted 9 years agosmart. jel!

JohnClimber: course rigids aren’t allowed! or i wouldn’t’ve said hartails!likes of trek and spesh come with blutos so are presumably suspension corrected geo.s tho not thatconsequential for 100mm forks.

how about the OO fatties and the puffin. are they ‘a bit sus corrected’, so to speak? or do they jsut not really mind?

jamiesiloFree MemberPosted 9 years agoloving that monster anotherstan!

where i live massive tyres just make sense, up to a point anyway. i can only fit 2.4s in my frame, but i’d love say 3″. don’t need to ride any tarmac and a lot of it is rough and rooty as anyhing.+1 for more pics anyways

jamiesiloFree MemberPosted 9 years agoi’m using jagwire outers and cables with BB5s, MTB ones, and they still have a somewhat spongy feel…

whether less so than if i was using ‘lesser’ outers i’ve no idea; haven’t tried