Forum Replies Created

-

Megasack Giveaway Day 16: Continental Argotal Tyres

-

eshershoreFree MemberPosted 12 years ago

any LBS trying to “price match” on-line retailers is slowly bleeding to death, even if they don’t realise it…yet :(

workshop jobs should never be done “for free” especially when customers have asked you to “price match” and then cheekily asked “oh, can you fit it for me for free?”

no one works for free, I am 100% sure the customer asking for price matching and free labour does not work in their job for “free”, bike shops are no different, just like any business with operating costs including payroll

I’ve worked for LBS, distributors, chain stores and even owned a bike brand and dealt directly with Taiwan and Japan

one LBS I used to work for, was ahead of the game, and sources lots of OE kit directly from its import brands (why not “sell” 1000 frames a year instead of the 800 you actually sell) and this allowed us to undercut other retailers buying through official distribution whilst maintaining our margins ;)

there is definitely a place for the LBS, its selling box brands from the big players (Specialized, Trek, Giant, etc.) that support their dealer network and don’t want their bikes sold on-line

and also offering expert advice to new cyclists, and specialist workshop services to both new cyclist and even expert cyclists (who may not have the technical skills, time or tools to perform this work)

at my current employer, 50% of last season’s profitability came from bicycle workshop servicing

“Service Centres” are on the increase, for very good reasons :)

eshershoreFree MemberPosted 12 years agoI’m going to have to defend Doddy here. – MBUK does what it does and it does that very well ,(Without people starting MBUK there would be no Singletrack or Dirt mag) Doddy does the job he’s meant to do for them and does it very well, He ‘s a very affable nice down to earth bloke ;]

Matt

^^ have to agree, I have done bike tests and a number of photo shoots (in the UK and Canada) with Doddy and MBUK and always found him a down to earth lad with a good sense of humour and very passionate about mountain biking

he’s also technically a good rider with a good clean style, if you have ever ridden with him!

this is from a shoot we did at Esher Pump Track

eshershoreFree MemberPosted 12 years ago

eshershoreFree MemberPosted 12 years agoon my last build (an all mountain bike) I veered away from my usual choice of thomson X4 stem and thomson elite seatpost, in favour of some Easton “Haven” finishing kit the shop was offering on a “deal” with the frameset

the deal was not actually cheaper than buying thomson kit at “street price” but the same price as the thomson street price (with some money off the RRP of the easton kit)

within a few months the Easton Haven seatpost looked like complete sh*t with loads of scratches / marks where I had moved the post up and down in the frame, and I was getting suspect creaking noises from the seapost’s saddle clamp despite use of anti-seize on bolts and torque wrench – never had this issue with the 8 thomson seatposts I have owned over some years!

the Easton Haven stem certainly looked the part when new and worked as well as the thomson x4 in terms of strength / stiffness with big 750mm bars

but in a few short months all of the mounting bolts had rusted (steerer clamp bolts x 2, and handlebar clamp bolts x 4) making the stem look really tatty – NEVER had this issue with the 6 thomson stems I have owned over some years!

with the brand new bike build, it was definitely back to thomson with the 70mm X4 stem and 410mm x 27.2mm Elite seatpost :)

eshershoreFree MemberPosted 12 years agoOut of curiosity do you think it brought money to Freeborn? And did they pay for the site or was it payment in kind for the maintenance and support?

Esher looked a superb spot, sad that I missed it.

it certainly brought some trade to the Freeborn Esher bike shop, in that it established a “venue” that freeriders and serious mountain bikers were prepared to travel to, because the shop had high stock levels of high end bike components, frames, forks, wheels, DH/FR tires and lots of full face helmets and body armour – these items were almost impossible to find in London shops

I know that Freeborn never got back the money (many £1000s) that was invested in the bike park setting it up, although it can be assumed that some of the profits made from selling kit in the shop would have gone back towards this investment

I also know that Freeborn did not charge the bike park for the admin side (memberships, day passes, etc.) or for their staff who worked in the bike park when the shop was quiet (typically winter), but their time was already being paid for by Freeborn, at no direct cost to the bike park.

we used to get lots of enquiries from people keen to set up bike parks, but when we met and explained that no one was actually getting paid solely to either build / maintain or operate the park

and that both the shop and bike park were paying a “peppercorn rent” with no business rates or utilities bills, for a piece of land they was useless to anyone else..with the shop tacked onto the side of a larger sports complex, they suddenly lost interest

eshershoreFree MemberPosted 12 years agofrom what I understand from industry sources, Joes and Stans sealant come from the same supplier

rim strips are slightly different in that Stans has a much wider range available?

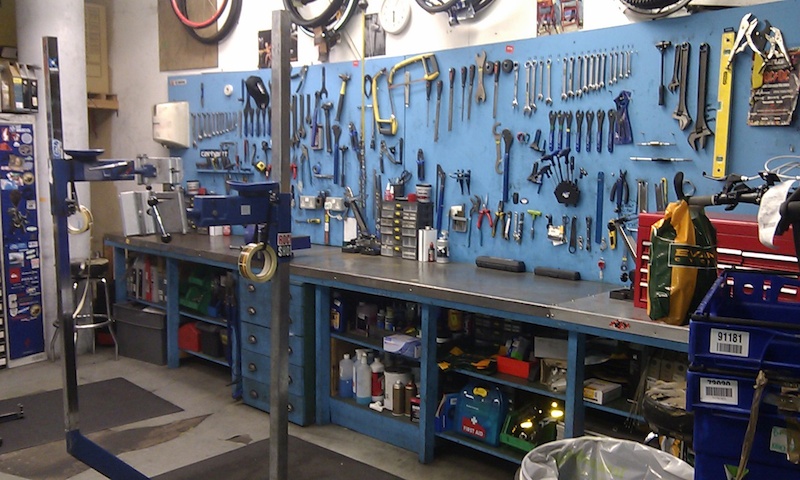

eshershoreFree MemberPosted 12 years agoan issue I have had with peg and hook tool boards is marking tool locations (especially as many peg boards are blue or silver i.e. not ideal for marking with a pen)

not a problem for “home use” but in a bike workshop you can go away for your days off, and come back to find several tools missing (borrowed by over enthusiastic shop staff who should know better…or quickly borrowed by a fellow mechanic and not replaced)

it can be hard working out what is missing, and where the missing items go when retrieved

the beauty of the shadow board is the instant visual identification, I can come into work, and immediately realise someone has borrowed my stanley knife, scissors and 15mm ring spanner, and go about finding them and putting them back in the right place.

eshershoreFree MemberPosted 12 years agosomething to consider about a “tool board” or “shadow board” is that you develop a memory of exactly where the tools are located on the board, rather than randomly throwing them onto a magnetised surface?

as a professional bike mechanic and workshop manager, I spend a lot of time working on shadow boards which includes actually building them and setting them up logically with reference to commonly used tools and sequence of tool use during common workshop jobs

these are some shots of my recent workshops

I’d highly recommend setting up a shadow board using 3/4″ ply and painted black with silver / white marking pen to outline your tools, and a mix of fixing to secure different shaped and sized tools to suit your needs

eshershoreFree MemberPosted 12 years agoI had a problem with a pair of Mavic D521 about the same time period as the OP mentioned

the cause was a worn rim die tool in the Mavic factory

I was told (by Mavic) that the worn tool meant the rim extrusion was slightly oversize, and when they fitted the eyelets there was a lot of stress concentrated in the eyelet drillings

on both my rims (built properly by cycle surgery in London) the rims started cracking around all of the eyelets, I was offered some Sun rims as an alternative at no cost and did not use Mavic for many years after that

however, as a professional mechanic I have since built many pairs of wheels using Mavic rims for road, CX, and mountain biking including XC, FR and DH and no problems to report for either my customers or myself

I current use Mavic A319 rims on my commuting bike which gets beaten through potholes, drain covers and kerbs and the rims are just fine ;)

eshershoreFree MemberPosted 12 years agoat the old Esher Shore bike park we had 3.5 acres but managed to fit nearly 4km of North Shore and a huge Pump Track into the space

the bike park was “not for profit” was built by free by volunteer labour, and all materials and tools, etc. paid for by industry sponsors like Specialized, DMR, Banshee, Devinci, Freeborn, Giant, etc.

no one was paid to run it, or work directly for the park, the freeborn bike park on site handled all the memberships and entry fees, etc. (admin) as well as supplying shop staff on a free basis to help with maintaining the bike park

the bike park never made any real money to reinvest despite during its heyday seeing 200+ riders a week from all over the UK and annual “jams” with 150+ riders and 200+ spectators

the takings covered expensive insurance, rent and ongoing work to maintain the trails

eshershoreFree MemberPosted 12 years agoI never bother bleeding Juicy’s with 2 syringes, but you will need the Avid bleed port fittings and Avid hose locks for sure! and some fresh DOT fluid (try Rock Oil 5.1 its cheap and good quality)

bled 100s of Juicys using this method:

fill a syringe full, de-gass and attach to the caliper with the hose lock shut (stops fluid running backwards when doing the below step)

for the MC (brake lever) loosen the handlebar clamp and turn the lever so its vertical (bleed port at 90 degrees to ground) then run a long hose into a catch bottle (old coke bottle) like with Hayes, but using the Avid bleed fitting on the lever end and with the hose lock 1/2 way along the hose, locked off at first

release both hose locks and whilst holding the syringe vertical (to stop any air going into the system) push the full syringe of DOT into the catch bottle, can always lock off lower tube and refill the lower syringe with another load of DOT if not 100% sure

once pushed through, lock off the caliper end using hose lock, you can remove the syringe without DOT leaking backwards, reinstall the caliper bleed port and wipe the little dribble of DOT with Iso alcohol or similar.

then turn the MC round on the bars so its horizontal and carefully remove the hose / fitting, and add a couple of drops to the bleed port (so it floods over) before refitting the bleed port. wipe off with Iso alcohol or similar.

never failed, and saves so much time compared to the “official” method

this will not work for Elixirs with pad contact adjusters though, only for Juicy and basic Elixir with only reach adjustment (ports sit at different height)

eshershoreFree MemberPosted 12 years agonot in my experience

tried running Stans with Mavic rim adapter plug (plastic piece) but found it leaked around the valve hole when using a presta rim strip in a rim drilled for schraeder

eshershoreFree MemberPosted 12 years agoa great tip I can pass along to you

choose a glove that has an outer glove, and an inner glove (I use Fox Anti Freeze)

or buy a regular winter glove in a baggier size and then buy some Altura liners (or similar liner glove)

put your liners on, and then put on workshop butyl gloves (or latex) on top of your liners (you can even use those PU gloves you can free at the petrol station next to the fuel pumps)

finally put your outer gloves on top of this combo

the workshop gloves stop any cold air that penetrates the outer glove from reaching the liners, you get a windproof lining with your liners underneath providing insulation!

the liners will get a bit warm / sweaty as the workshop gloves stop the heat and water vapour escaping

but you will have toasty hands, regardless of the weather! happy trails…

eshershoreFree MemberPosted 12 years agoesher shore –

just sold a 150mm FS and am looking at getting one of the Stupmjumper evo 29ers for all the same reasons. Just wondering how your getting on with it?

its certainly a different kind of riding experience, and one that I am thoroughly enjoying! (after years on suspension bikes)

came back from the riding in the snow, let the bike drip dry on some newspapers

oiled the chain, cleaned the fork seals with Finish Line dry lube, put the bike away…wonderfully simple to maintain / clean compared to FS bikes

one thing I will say for sure, its definitely still a mountain bike and enjoys being ridden aggressively, and will carry you across soft and mucky ground much easier than 26″ wheels

eshershoreFree MemberPosted 12 years agothe build tension is slightly higher on the SP setup but its doubtful it would be *really* noticeable?

the issue of sourcing straight pull spokes would be a pain, compared to the J-Bend spokes on the regular Evo hubs?

eshershoreFree MemberPosted 12 years agoesher that workshop is sweet man good work.

Any clues to where you are nowadays esher? It’s always good to know where there is a shop with excellent mtb knowledge in London.a well known bike shop opposite Waterloo Station in London SE1 ;)

eshershoreFree MemberPosted 12 years agoHope Hoops every time

all hub spares available next day from Hope dealers, and Hope in the UK give excellent backup for any warranty issues, plus multiple axle setups including QR, QR15, 20mm, 135 OLD QR, 135 OLD screw-in bolt and 142mm x 12mm syntace using affordable adapter kits

the Hoops use regular J-Bend spokes and brass nipples, meaning replacements are very easy to source (walk into any bike shop..) and cheap too

the Stans ZTR rims are excellent with great strength to weight ratio and easy installation of tubeless conversion systems, with secure bead lock on tubeless ready tires and good reliability in terms of tubeless security over time

rims are also readily available if you mangle a wheel in a crash!

eshershoreFree MemberPosted 12 years agosome of the aftermarket disc brake pads have paint or excess material on the backing plate of the pad, that stops the pad spring fitting properly onto the brake pads and stopping you from making the “pad sandwich” Avid talk about in their literature

you will see the pad spring start to “flare” when trying to fit to these pads, only when cleaned off, will the pad spring sit flat alongside each pad

take a flat needle file and file off any excess paint or material so the pad spring fits correctly onto each brake pad

push your pistons home with the ring end of a 10mm ring spanner, if you cannot get them to seat you need to reduce fluid volume; open the bleed port on the MC (brake lever) and then push the pistons flat each side with the ring spanner, you will see a little DOT leak out of the port

reinstall the bleed port on the MC, you should have no trouble fitting the pads, but watch out for the caliper’s pad spring plate, as this can move when refiting pads

often it helps to firmly grip the new pads’ mounting tab (the bit that sticks out the top of the caliper) with pliers and wiggle / SNAP the brake pad into place, you will hear it click home once located

if you cannot get this snap, you need to reset the pistons flat into the caliper body, or reposition hte caliper pad spring plate, as this often moves when messing around with the brake setup!

eshershoreFree MemberPosted 12 years agoesher shore – what frame is that? Chi carbon?

@ monkeyboyjc

2012 Specialized Stumpjumper Evo 29’er – M5 aluminium alloy (7005 T6)

another shot from a recent day on the trails in NW London:

eshershoreFree MemberPosted 12 years ago

eshershoreFree MemberPosted 12 years agodon’t want too much grease in there, just retards the free movement of the pawls / springs and will accelerate wear and tear as well as reducing freehub performance under load

always rebuilt mine (2 sets of wheels) with a couple of drops of Finish Line Dry chain lube after cleaning, and gotten very good performance and long durability, with plenty of clicky Pro II noise to enjoy when freewheeling

done this for plenty of customer’s wheels with no issues to report

if the clicking irritates…you are not pedalling fast enough ;)

eshershoreFree MemberPosted 12 years agoI’ve just dumped my 26″ 150mm FS for a 29’er hardtail

I rode a number of 26″ hardtails and could not seen the benefit / point of another 26″ hardtail, over retaining my FS bike

I reckoned a 29er made much more sense for a hardtail, whereas I cannot really see the point of 29er FS? (would rather buy another 26″ FS bike)

here it is:

eshershoreFree MemberPosted 12 years ago

eshershoreFree MemberPosted 12 years agobeen using dish washing detergent (fairy liquid, etc.) to clean off-road bikes for 25+ years (including modern bikes with suspension and disc brakes) and no problems to report?

tried muc-off, sh*t shifter, fenwick, etc.

found it less effective at shifting the built-up mud (often seen mud stains still on the bike after cleaning and rinsing using these products)

its a complete rip-off compared to £0.99 dish washing detergent which cleans a hell of a lot more bike than a bottle of muc-off??

and Muc-off made some of my anodised components (especially Sun rims and race face stems) change from a black colour to a copper / brass colour and that was only 10 minutes of cleaning and then rinsing

never had that issue with dish washing detergent?

eshershoreFree MemberPosted 12 years agohave a look at Shimano’s cheap but durable SLX cassette in the 9 speed variant with 12-36T ratio

I am riding a 29er with 33T and 11-36T rear in 10 speed, and find it perfect for climbing up very steep hills (standing) and also bombing down the steep hills

eshershoreFree MemberPosted 12 years agoits a big shame if that crankset has been dropped by Shimano

easily the best value, very tough crankset for 68mm/73mm bottom brackets ever made!

I had 2 pairs of these cranks on a number of different bikes and beat the absolute sh*t out of these cranks with no issues at all

did stuff like this, on my 100mm travel 4X bike with the SLX cranks

eshershoreFree MemberPosted 12 years ago

eshershoreFree MemberPosted 12 years agowent through 3 pairs of MG-1 in one season (got them super cheap), all died from the same problem

the bearing “flogging out” the pedal body bearing socket, and causing movement / clicking

my riding buddy had the same problem with his 2 pairs of MG-1 and ditched them for Electrons

I have been running Nukeproof Electrons since last Autumn and no issues to report yet, heavier than the MG-1 but a bigger / thinner platform, full spares available cheaply through Hotlines dealers

eshershoreFree MemberPosted 12 years agonot really convinced?

had an unhealthy number of commuting bikes come through the workshop all with Gates belt drive issues, bear in mind these are commuting bikes and not even ridden on the dirt in wet / muddy conditions

typically:

– stripped drive cog (rear cog / freehub body interface is mangled)

– damaged freehub body bearings

– damaged bottom bracket bearings

– belt constantly “crabbing” under power and getting stuck in rear wheel spokes or frame tubingunless the frame alignment is very good, and belt tension is near perfect (Gates actually provide a “tuning fork” to set the belt tension at the correct frequency???) the system tends to self destruct

its too easy to set the belt slightly too loose, which results in the belt slipping under power over the rear cog (called “ratcheting”)

or set the belt slightly too tight which results in the bearings in either the freehub or bottom bracket taking a beating and quickly failing

so the local mechanic using the tuning fork (I have yet to actually see one in person) or the new I-Phone APP (I kid you not..) gets it set up perfectly for you, until you get a rear puncture and have to pull the wheel off, and then the belt tension is all buggered!

Gates are now introducing their new belt system with the central spline to aid in keeping the belt running true on the cogs, and to flush any debris from the drivetrain especially if running off-road

thanks but not thanks…I will stick with the humble chain myself ;)

eshershoreFree MemberPosted 12 years agoa tight workshop…

….this is the “engine” of your bike shop

a good workshop manager can make / break your bike shop, alongside a good shop manager with an eye on the “profits”, not ‘giving it all away for free’

this is my workshop, and I run a tight ship

eshershoreFree MemberPosted 12 years ago

eshershoreFree MemberPosted 12 years agoDON’T use DOT fluid to “lube” your disc brake seals, its not a lubricant in any sense and makes the seals swell, it will certainly help with initial re-installation when rebuilding a caliper (pushing pistons into the caliper halves) but that’s all it will offer…

…what you need is silicon grease, although this involves stripping the brake calipers and a full rebuild with rebleed which is pain for most home mechanics

if you buy a Hope “tackle box” for a bike workshop kit it contains Hunter silicon grease for the caliper piston seals, we also have supplies of RS silicon grease for Avid, Shimano and Hayes rebuilds

a quick fix (temporary) is to remove the brake pads and pump the pistons out several cycles using the brake lever (but not so many times they fall out!) and then apply a silicon spray like “Fork Juice” before reseating the pistons with a 10mm ring spanner

before reinstalling the disc brake pads, make sure to remove any excess silicon from the caliper bay using iso alcohol or disc brake cleaner

eshershoreFree MemberPosted 12 years agofantastic tires for aggressive riding in loose / muddy conditions

no problems inflating on Stans rims, will inflate even with a cr*p track pump!

all the tech of Cheng Shing (Maxxis – they make Specialized tires BTW…) without the high RRP, and a much better tubeless-ready liner without the weight penalty

would not recommend using the Eskar on the front if you value your teeth…speak from experience and that of several riding friends

would recommend the Specialized Purgatory or Captain 2.2 as a much more suitable front wheel companion for the Eskar on the rear

if you ride a lot of fireroad or harder packed trails (or just drier conditions), would recommend the Captain or new Ground Control as better alternatives to the Eskar, on the rear!

eshershoreFree MemberPosted 12 years agoclean the stanchion before fitting the clamp, use a torque wrench and no more than 5nm

the stanchion is hard anodised, and the clamp is finished to very high tolerances, you will not do any damage if fitted properly…

eshershoreFree MemberPosted 12 years agoEaston for handlebars

Thomson for stems and seatposts

SRAM for shifters, derailleurs and cassettes / chains

Shimano for Hollowtech II cranks, rim brakes and SPD shoes(road) and gear cabling

Avid for hydraulic disc brakes (mtb)

Fox for suspension forks and shocks

5-10 for riding shoes

Specialized for tires and frames

ODI for lock-on handlebar grips

WTB for saddles

Hope for wheel hubs and night riding lights

Stan’s for wheel rims and tubeless sealant

E13 for chain devices

FSA for headsets

eshershoreFree MemberPosted 12 years agowould expect to pay 50% for a custom bike up-front, and balance on collection

this way its not legally registered as a “deposit” which is in essence, refundable (meaning the shop takes the hit if you walk..)

50% would be part-payment, and not refundable unless the shop failed to deliver the goods in the allotted time frame (they have then broken the sales contract with you)

50% payment would protect the shop for the risk of custom building a bike as you have then entered into a binding contract, and also cover the “cost” of many of the parts required for the custom build, so everything received in the balance is their profit / time

a production (stock) bike is a different matter because its just one of many exactly the same…would not expect to pay more than 10% deposit to “hold” a bike some weeks out from being available

and pay with your credit card, as others have suggested.

eshershoreFree MemberPosted 12 years agoin my workshop I have 4 Kestrel (UK made) Model-E steel floor stands which sell around £400 each, these are seriously overbuilt bits of kit and very common to most UK bike shops

at home?

I have a basic Park PCS-9 and its a fantastic home repair stand, no complaints from me at all

at home you are not constantly clamping bikes into your stand (unlike being at work..in a bike shop’s workshop) and so the PCS-9 clamp works just fine for occasional use :)

eshershoreFree MemberPosted 12 years agothe trailstar has not been manufactured for a few seasons now

one of my buddies recently picked up a Trailstar frame for £50 thinking it would be a great all rounder for messing around at Woburn / Chicksands and winter trail rides at Swinley

but said the TTL, HA and BBH felt completely wrong compared to modern frames, and promptly sold it and bought a Stanton slackline

eshershoreFree MemberPosted 12 years agoand this is where the problem lies with using the “right” version on the left

when you mount it on the left (for 1 x 9 or 1 x 10 setups) the trigger sits on top of the bar and becomes very vulnerable to getting snagged on clothing and snapped off

as I found out, when to climb a steep chute, the bottom of my riding shorts snagged the trigger and snapped the shaft clean off

SRAM (Fishers) were brilliant and replaced the damaged part FOC within 3 days, but after this I had several moments where I caught my shorts again and managed to stop moving before the trigger snapped off…

eshershoreFree MemberPosted 12 years agoselling off my 150mm all-mtn (Devinci Dixon) to fund a 29er

this, if plans go ahead, should be here in early Feb :)

eshershoreFree MemberPosted 12 years ago

eshershoreFree MemberPosted 12 years agowelcome to road bikes!

every mountain biker should have one, they are great for going out riding (to keep fit and get your cycling fix) when the weather is filthy and you are fed up of spending 45 minutes cleaning your mountain bike and kit after every ride!

its great to own different kinds of bikes, have fun with your road bike :)

eshershoreFree MemberPosted 12 years agoI use cardiotrainer from worksmart labs.

its not 100% accurate but for a free app its pretty damn good

it shows a map of my ride (with timed waypoints), along with overall time, distance, calories, min+ max speed (including a graph screen with all the speed changes throughout the ride), tells me total climbing distance and altitude

also talks throughout the ride giving regular updates as to time elapsed and distance travelled, and autopauses when you stop, and restarts when your start moving again.

lets me record as history or share to social media, and has multiple setting including hiking / running / cycling / mountain biking, etc.