Forum Replies Created

-

It’s not easy being Singletrack. Please help.

-

eshershoreFree MemberPosted 11 years ago

its not easy, or everyone (with some spare cash) would be doing it ;)

a few years back, I worked for an established importer with 3 exclusive import brands (1 Canadian owned / manufactured, 1 USA owned / manufactured and 1 Canadian owned / TW manufactured)

we sold direct, did very good business. but it was always a struggle to get enough funds to do PR (which included print and web advertising, bike mag test bikes and rider sponsorship), to get the “word out” to the cycling public

bearing in mind, each of these 3 brands were well established

our biggest selling brand? The only “boxed brand” we sold which was Specialized Bikes. Outsold our own brands perhaps 3:1, which tells you the power of branding and big brand value compared to trying to establish your own marketplace

something else to be very concerned about in terms of a business risk is warranty issues; a run of warranty issues can completely ruin a brand in terms of profits and consumer confidence

let’s just say one of the 3 exclusive brands we sold, is no longer part of my previous employer’s roster, but was let go after ongoing warranty issues proved somewhat costly to any profits and more importantly the brand’s reputation in the UK :(

eshershoreFree MemberPosted 11 years agowell the 2 largest quality bike “chains” in the UK are really struggling to find competent mechanics and sales staff because of their poor terms and conditions (minimum pay with no holiday, temporary contracts and no training)

staff generally get some experience and make a sharp exit to the nearest LBS…

good luck to Halfords finding any competent staff prepared to work under such similar poor terms and conditions

eshershoreFree MemberPosted 11 years agogood work fella!

I would say from experience running a smaller rear rotor will lead to better modulation (allowing adjustment of bike position going into corner) and less brutual skids (locking up brake..)

but of course this depends on skill of rider than just rotor sizing?? and you will always need a little sliding (skidding) to position the rear using the rear brake

eshershoreFree MemberPosted 11 years agogood points – the problem with road bike fitting is that its extremely personal, in terms of what will work, and what feels just wrong

takes time, experience and money

even the type of bar tape used, and the way its wrapped, makes a big difference to your setup…in our workshop we can use 5 different bar tapes from the same brand, some thicker, some thinner, some different widths, some with gel inserts, some available with plastic cable hose covers, it all changes the way the bars feels in a dramatic way

eshershoreFree MemberPosted 11 years ago80% of brake power on the front brake?

if you study the effect that braking has on your bike, hard braking rotates the bicycle against the front wheel axle, lifting the rear wheel off the ground, making the rear brake less effective

you can counter this by leaning right back when making a really hard stop, to try and pin the rear wheel to the ground, but it will always slide when locked up hard

so rear brake is used in combination with front for hard stops, or more commonly rear brake used for adjustment of bike position going into corners

very common to use larger rotor on front, and small rotor on rear

many pro DH racers use 160mm rotor on rear for this reasons (these guys also don’t plan to do much braking on the rear during their run)

eshershoreFree MemberPosted 11 years agotry the Specialized BG Compact alloy bars, about £35 if you shop around? Easy to find in any Specialized dealer, very neutral shape with compact sizing

bar size is linked to bike frame sizing, in that smaller frame sizes will come with 40 or 42cm bars and larger frame sizes 44cm upwards. women’s bikes will run smaller width bars than mens for obvious reasons :)

not worth bothering with CF bars unless you know exactly what you want in terms of size and shape, and have money to splash about (there are better weight savings to be had for the same money on a road bike..)

recently? I was running Specialized alloy bars, had an opportunity to upgrade to a Specialized carbon fibre bar in the same size at minimal cost

all I can say its a difference in comfort on rougher roads, rather than weight or stiffness.

eshershoreFree MemberPosted 11 years agoI’ve been wearing Oakley for many years because I believe in my experience of using and selling many brands, they have the best lens quality and impact protection of any sports sunglasses on the market?

probably the biggest issue I would have with cheap / fake sunglasses is simple; whether its going to provide proper UV protection for your eyes?

and if you take a smash, whether its actually going to protect your eyes or cause damage?

I am typing this, with a 1″ scar on my left eyebrow from a “branded” but cheaper pair of clear glasses (used for night riding) that failed in an impact, with the frame actually cutting me open, requiring hospital treatment

eshershoreFree MemberPosted 11 years ago@tin_pin_man

not loosing your marbles at all fella! good memory for sure ;)

I rode with Northumbria Uni MTB Club, along with Phil Hammil (now one of the managing directors of Madison a.k.a. Shimano UK) and regular guest riders Jason McRoy and Paul Plunkett

I also worked for Hardisty Cycles and was a team mate of JMC (until Margaret Hardisty fired me because she heard I was importing “Mongoose”….in others the AMP rear kit used for the Mongoose Amplifier she was occasionally selling)

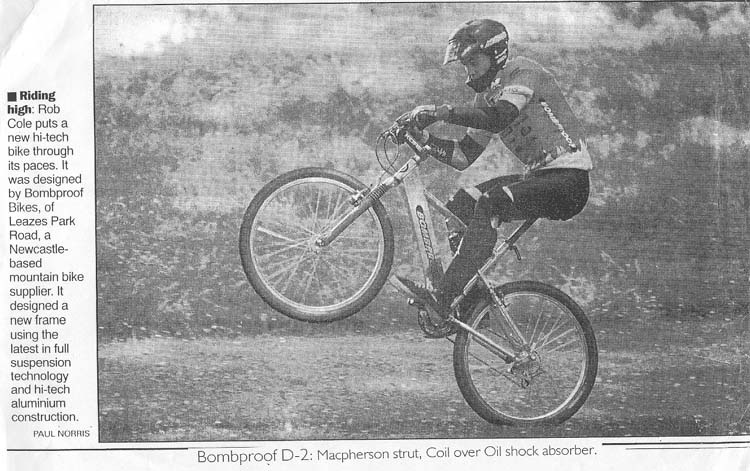

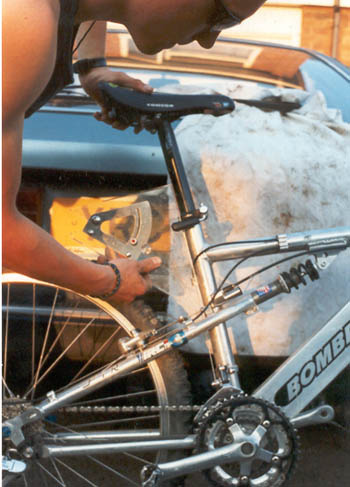

here are some more retro shots from the Bombproof era. We finally wound the company down in late 1996 after our Australian manufacturer ran off with all the money we had invested in our first production run of frames (along with money from another 4 companies)

eshershoreFree MemberPosted 11 years ago

eshershoreFree MemberPosted 11 years agoI used to deal directly with Horst Leitner at AMP when I was running Bombproof out of Newcastle in the early 90s, this was before the FSR licensing deal he brokered with Specialized USA

we were buying his rear suspension “kits” for our Bombproof front triangle that was being manufactured in Newcastle

although we machined our own mounting hardware (the AMP swingarm tabs and shock mounts were flimsy) and soon moved to Noleen shocks and TWP braces

the long unbraced seat stays on the AMP rear put huge loads on the AMP coil/oil shock which was a “stressed” member = oil leaks, a common problem until the revised AMP came out with the interrupted seat tube, and then the small swinglink which was the development leading to FSR

eshershoreFree MemberPosted 11 years ago@quarz

it can happen, have seen it with all the big brands from time to time:- Specialized, Trek, Giant; all taken care of quickly with no fuss / cost

but seen more commonly with smaller brands like Norco, Mythic, Fuji, Kona, etc. lots of time and costs involved, sometimes months to get a resolution.

most importantly with any genuine warranty issue?

How quickly YOUR problem gets dealt with – how quickly YOU get a new frame / bike and back out riding, that is all that matters in these instances (and you don’t get palmed off with another of the same problem…but a revised version, or one with proper QC, which you admit SBC failed you in that instance!)

regarding the bigger brands, part of the high “cost” you pay when you buy their frames / bikes is generated by them having a dedicated, domestic distributor with people manning telephones, a warehouse full of replacement parts ready to ship, and procedures in place to deal with these problems when they arise from time to time

eshershoreFree MemberPosted 11 years agobig difference with fake I-Pad and fake bicycle frame?

..you don’t ride an I-Pad, if the I-Pad bricks itself it won’t put you in a wheelchair or require a trip to the dentist for expensive treatment ;)

personally, I would be concerned to take an unknown bicycle frame down a steep road hill at 40mph, results could be ‘interesting’ to say the least?

Might get away with it, might not….welcome to the live experiment?

If you work every day on high end road frames, its actually not hard to know what to look for when examining genuine frames versus fake frames.

Finding paper / newspaper (!), bladder debris, bits of ??? inside the tubeset is not confidence inspiring, especially where the head tube is glued to the downtube. Finding fibreglass or plastic mesh inside the tube set is not confidence inspiring.

Checking frames with fore / aft alignnment 40mm out, is not inspiring.

something I would say from my experience is that some of the “unbranded” frames, that are identical to “branded” frames are often units leaked by OEM suppliers with excess capacity (just like OE groupsets, wheel and finishing kits that regularly wash up on the shore of the on-line re-sellers)

rather than a crude attempt by a counter-fitting gang punting dodgy branded frames through Alibaba Express or Ebay, to screw you out of your money with no regard for your safety on the road

eshershoreFree MemberPosted 11 years agodealt with way too many road customers in the past 2 years who have thought they got a “good deal” buying their frame from alibaba express; a fake Pinarello Dogma, Trek Madone, Specialized Tarmac or whatever it is supposed to actually be?

my experience is usually the customer bringing said frameset to the store, asking my workshop to build it up with some equally dodgy Campag or ZIPP wheels from same website

my mechanics cannot build the bike to required safe quality because the frameset and wheels are very poorly finished and have alignment / tolerance issues. Cabling does not install properly, rear wheel sits skewed in dropout, seat tube angle incorrect for Shimano’s front derailleur tolerances, etc.

On some occasions we cannot even install the seat post to the frame because the seat tube has rippled internal diameter not allowing seat post to slide down for clamping up into the workstand!

Customer will then admit where they got the items from, and either attempt to get their money back (good luck?) or find another bike shop willing to take a hacksaw to the items to make them fit together

also had customers bringing their “fake” bikes into the store, asking us to sort out gear shifting or handling issues, only for use to discover all kinds of fitment and alignment problems with our tools, cannot solve problems and send customers on their way with our best wishes for good outcome

would not touch cheap carbon fibre frames or wheels with bargepole.

If you get your hands on one of these cheap framesets, pull the fork off and take a dental mirror and torch, start closely examining the inside of the frameset, then compare to a genuine Specialized / Trek / Giant or even a smaller genuine brand;

its a night/day difference in manufacturing quality and what you see inside the tubing of a cheap frame will actually shock you if you have experience in these matters ;)

always recommend a quality aluminium alloy frameset over cheap CF frameset, any day…

eshershoreFree MemberPosted 11 years agoget fitted properly by an experienced bike fitter.

many riders using old information end up on a frame 1 size too large for their ideal setup.

get the smallest frame which fits properly, will allow fitting in “both directions” (shrinking or expanding) by adjusting stem, seatpost, saddle, pedal cleats, crank length, bars, bar taping, control setup, etc.

look carefully at your drop and reach. saddle height is critical, many run it too high..

personally? I ride a 54cm race bike (Specialized Tarmac) but with less drop and less reach than would be normal, it fits me perfectly now!

had a fitting session which made fundamental differences to my setup; something that came out of that session was difference in my leg lengths which is very common for many riders, and causes instability / pain / injury unless compensated for during the fit.

the fit also addressed the right shoulder pain I can get from repeated dislocations during years of freeride mountain biking and other extreme sports

“good fit” is one of those things that I would not suffer from doing 20-30 miles locally on a Saturday morning ride

but yesterday doing 104 mile ride solo in strong winds from Milton Keynes back to London through Bucks/Northants/Herts; good fit makes a massive difference between completing the ride and baling out to take a train home, 1/2 way through the ride

wheels and tires very important, I run handbuilts (Hope hubs on Mavic Open Pro rims with d/b spokes and Specialized Roubaix tires), quick light but also comfortable and shrug off potholes impacts!

quality clothing like comfortable bib shorts (with chamois cream), fitted shoes with proper footbeds and shims, merino wool socks, overshoes if cold, knee warmers, good gloves, upper layers, correct hydration, energy foods, some nice coffee whilst taking the train before the ride, all make a big difference for the long miles

eshershoreFree MemberPosted 11 years agoowned a Specialized Tricross CX bike, several seasons back and found it too compromised to be worth keeping

slower on the road (even with road tires), not much use off-road (compared to the MTB)

would always choose a proper MTB or proper Road Bike, than a compromise

eshershoreFree MemberPosted 11 years agowell worth doing

even a basic road bike like Specialized Allez Sport would be ideal for commuting with some SPD pedals and shoes (whether mountain or road)

will make a big difference to your commute :)

eshershoreFree MemberPosted 11 years agoown a couple of high end bikes, including Specialized Stumpjumper Expert Carbon 29’er hardtail with 1 x 10 Sram X-0 gearing, and Specialized Tarmac Carbon road bike with Ultegra 2 x 10 gearing

simply no comparison between the MTB and Road Bike for riding speed and distance travelled for effort put in…on the road, the road bike simply kills the 29’er MTB, and first to admit the 29’er are much quicker rolling on the road than the 26″ mountain bikes

love both bikes, but for commuting it would be the road bike every time, unless its snowing when the MTB would be the instant choice ;)

eshershoreFree MemberPosted 11 years agoits back to Banshee Bikes in the UK, something that the Banshee guys put right when they moved to their new UK distributor ISON

when Freeborn were doing Banshee it had to become “Mythic” because of the Halfords “Carrera Banshee” trademarking; Freeborn were warned by Halfords Legal people to leave the issue alone

turns out in the early days when this issue was being looked into, one of the original Canadian owners of Banshee only made it as far as Heathrow Airport / Hotel and did not make the meeting with Halfords..

who were somewhat miffed and therefore less than keen to come to a compromise over the issue when Freeborn made an attempt to talk to them

eshershoreFree MemberPosted 11 years agoits a sad fact that the bike industry has invested very little time, effort and hard cash in training their staff members, whether sales people or workshop staff

the industry is on the up and up, as more consumers get into bikes, but pay, conditions and training have not kept pace with the profits. Actually, many staff are now on zero-hour contracts on minimum pay, and of course for such “disposable assets” you would not expend profits in training these “numbers”, but that’s another story entirely…

its not a secret that many of the bike shops in London actually relied on Evans Cycles to train workshop staff up to Cytech 1 / 2 / 3, and then to take on these ex-Evans staff, at no cost to the new employer

unfortunately for these bike shops, Evans don’t offer Cytech training any more, just their unrecognized, in-house “Evans Academy” ‘Bike Builder’ training

shame, it means these other shops might have to start paying some of their profits to actually training their workshop staff

the sad thing for the sale staff is that a few hundred ££ spent with an experienced sales training coach will reap instant dividends for sales staff to learn how to control and close sales, but once again…the bike shops are too stupid to realize this potential :(

eshershoreFree MemberPosted 11 years agoJMC = legendary dude. had the honour of being his team mate at Hardisty Cycles (Byker, Newcastle) before he got signed to SBC USA

what about this for eye candy..currently residing at Specialized UK in Chessington, Surrey

eshershoreFree MemberPosted 11 years ago

eshershoreFree MemberPosted 11 years agoyeah, we have some carbon fibre, bolted seat clamps at work, £40 each (!!)

eshershoreFree MemberPosted 11 years agoSpecialized Control Captain front, Specialized Control Fast Trak LK or Renegade rear

both setup with Roval rim tape, suitable valve cores and Stan’s No-Tubes (tubeless fluid)

ideal setup for fast rolling 29’er which will prevent penetration punctures (the Fast Trak and Renegade have a thin casing)

you can use another Fast Trak on the front, but if you ride lots of trails with loose dirt / sand you will need something grippier like the Captain on the front

eshershoreFree MemberPosted 11 years agoEaston Havoc, Haven or Thomson X4?

owned Easton Haven 55mm stem and Thomson X4 50mm stem on same bike (Banshee Rampant 100mm FS 4x bike used for dirt jump, pump tracks, etc.) with same bars in 740mm

Easton Haven definitely stiffer when really honking hard on the bars or performing stunts ;)

if you look at the Haven, its an updated clone of the Thomson X4 with a wider stem body and clamp face (using their face plate locking system), I guess the redesign of the body is where the stiffer structure comes from, despite the Easton stem being lighter?

Easton is also “forged” rather than “CNC machined” like the Thomson, which unless my industrial design degree educated me incorrectly, is a superior process for strength to weight ratio, but setup costs more unless selling higher numbers (Easton have a healthy OE business compared to Thomson which is a niche brand)

the only downside to the Haven is that the stem bolts rusted very quickly, compared to the bolts on the Thomson which never rust..I hate rusty stem bolts on a bike!

currently? I am running Thomson X4 in 70mm with Easton Havoc aluminum 750mm bars on my XC bike and it feels just fine, and no rust! I don’t put that bike through the same abuse as the 100mm bike which I no longer own, so its all relative really?

eshershoreFree MemberPosted 11 years agoloud bell on my commuter, use it in London all the time, very useful to alert dopey pedestrians who step off the pavement without looking

not on the MTB or Road bike though as both have Hope hubs and a quick freewheel is very effective…

eshershoreFree MemberPosted 11 years agohold is pressurised (otherwise the plane’s structure would fail) but not ventilated with bleed air from the engine cooling like the cabin is

this means its cold down there..and they usually have a small heated area which live cargo (pets) are put into to keep them warm

your bike tires don’t need deflating to go into the hold ;)

eshershoreFree MemberPosted 11 years agochain measurement gives you an indication, but not the complete picture

I’ve had numbers of customers who constantly commute using a compact chainset on a road bike meaning constant 11T and 12T use, the chain is not beyond stretched according to tools, but once measured with the cassette wear tool its obvious the smaller cogs on that cassette are worn through, and chain is slipping under power

eshershoreFree MemberPosted 11 years agoTRAILRAT is correct :)

Park Tools have declined in their choice of suppliers during the last couple of years, do not assume older Park tools are the same quality as current items ;)

we have seen this specifically on their pedal spanners, screwdrivers, spanners and cable cutters.

I would not touch any generic, non-bike specific tools (screwdriver, spanners, adjustable wrenches) from Park; you can buy much better quality alternatives at better prices if you shop around (as long as you can live without the fancy “blue dip” on the Park handles)!

recently? when running a busy London bike store workshop for the flagship branch of a leading chain store, I had 6 mechanics working 7 days a week.

you would not believe how quickly current generation Park tools wore out, compared to other brand alternatives. Even the company management soon realized this, and switched our suppliers for non-bike specific tools.

personally? I would always purchase Pedro’s bike specific tools above Park, when available…

eshershoreFree MemberPosted 11 years agoin Scuba diving (I was a BSAC Dive Leader) it was always spit or fairy liquid in your goggles before rinsing out with ambient water

in cycling? I’ve been using Specialized Toro glasses for years which thankfully have a vented lens design which means no fogging, even during wet / warm winter rides at low speed, once you start moving the lens instantly clears

shame they don’t make the damn things any more…!

eshershoreFree MemberPosted 11 years agodid you use a Park cassette measurement tool before replacing your chain?

too much experience with the common chain stretch tools shows that they don’t examine wear to the rear sprockets of your cassette, especially in the smaller cogs where lack of chain wrap accelerates flog out of the cogs

lost sight of the number of times I trusted the “chain checker” only to find the chain slipped on the smaller cogs, or shifting did not work properly

these days? I just run the chainring, chain and cassette until it physically starts skipping, and then replace the entire lot (often with the rear derailleur or at least the pulley wheels of that rear mech)

eshershoreFree MemberPosted 11 years agonope…get the Float conversion, it allows proper sag setup, a much more reactive fork (small bumps!) and you can quickly / easily reduce the fixed travel using the spacer adjustments

you will find that a Float fork sits deeper into the travel when the sag is properly setup, than a TALAS which always “sits high” when setting sag

I converted a number of Talas forks to Float forks for myself and many customers, and none ever reported missing a travel adjustable fork, all reported good benefits to a more plush fork that worked properly ;)

eshershoreFree MemberPosted 11 years agono love for Park cutters here either..apart from the cable crimping function

Park simply do not last in a workshop environment, but for home use they are ok although overpriced compared to ice tools, etc.

in our workshops? we use Knipex 74-180 for cable cutting, they last for years. Most Evans and Cycle Surgery workshop use them too

eshershoreFree MemberPosted 11 years agocoming at this from a different angle, I deal daily with warranty and crash replacement for a big brand in London, who sell both aluminium alloy and carbon fibre road bikes and mountain bikes.

their frames have a limited lifetime warranty and lifetime crash replacement scheme (frame at cost) for original owners.

I undertake warranty for customers who have not purchased their bike(s) from our centre, so see a lot of quantity coming through.. from many riders who have bought from many different dealers in the London area, or further afield (at times, from riders who purchased elsewhere using mail order, or have moved to London since purchasing)

what I tend to see is more aluminium alloy frames that are often 3-5 years old, with cracks across welded junctions, often from fatigue rather than crash damage. we get the occasional aluminium frame with a large dent or crack caused by a catastrophic collision.

at previous employers (selling many different brands) I have personally dealt with many aluminium alloy frames, both brand new and used, with poor frame alignment that causes gear/brake and handling issues.

A good number of these have been post-crash, where the frame has bent. We have measurement tools and BS6102 stipulates specific tolerance ranges for these measurements, I have no problems rejecting poorly aligned frames using this information

what I tend to see more with the carbon fibre frames of road and mountain varieties, are crash damaged items

where the cyclist has hit a car (or been hit by a car), ridden into a lamp post or kerb edge, on the mountain bike frame impacted a rock or large tree. causing a impact fracture to the CF frame.

I have generally found the alignment on the “big brand” C.F. frames to typically be less than 1mm, and anything outside of this is either a QC issue or a large impact that has compromised the frame’s structural strength which may not be visible to the surface.

Some of the smaller brands C.F. QC alignment have been horrendous, and I’ve dealt with too many fake Chinese Ebay cloned frames that you simply cannot hope to build into a working bike!

occasionally we see a crack caused by a manufacturing issue, usually around the BB area or a brake mount

something I would say is that it seems that less experienced riders with lots of money are buying numbers of C.F. road bikes, and having frame failures caused by catastrophic impacts due to inexperienced road craft.

one recent customer was found unconscious in Regent’s Park, and his road bike was in several pieces, with him having no recollection of the incident.

I understand the engineering, manufacturing and QC issues behind aluminium alloy and carbon fibre / composite frames, and have no qualms in riding either material for both road and mountain use

both my current bikes (road and mountain) are carbon fibre ;)

eshershoreFree MemberPosted 11 years agosimple, use a Rivnut

we regularly repair frames (sometimes on brand new bikes) where the original rivnut fitting has become damaged, or was not installed properly to start with

the gun we use is Emhart Technologies “Pop Nut PNT 110” and the rivnuts are standard M5 steel

eshershoreFree MemberPosted 11 years agoyou can “flow” and generate “pump” on any wheel size, on any trail where favorable terrain presents itself. This generally means bumps, hollows, berms and elevation drop

I’ve spent years riding 20″ (bmx), 24″, 26″ and now 29″

I can pump my 29″ on the singletrack where the terrain presents itself, and accelerate without pedalling, using body strength to force the wheels to track the bumps

its all about the technique, it will come with practise :)

In addition to many years riding BMX which is all about flowing

I spent 2 years building and riding the old Pump Track at Esher, which definitely helped my understand and technique of “flow” on the bigger wheels

in this image, I am manualling my bike, whilst pumping the bike through the pump bumps

eshershoreFree MemberPosted 11 years ago

eshershoreFree MemberPosted 11 years agoI am actually riding more than ever, because I don’t work 6 days a week or commute long distances anymore

I never “trained” when I rode FR bikes, I just rode them to where I needed to get to (usually to a train station, and then taking a train, and riding from that station to the venue)

these days? I even run several days a week, do weight training and ride road and mountain bikes every other day. I am certainly doing more mileage.

whatever this has to do with heavier / lighter bikes I don’t really know; I apologize I am not a professional trainer? My current bikes are certainly much easier to pedal than my FR bikes.

eshershoreFree MemberPosted 11 years agobeen thinking about this a lot recently? we’ve been talking about it in the shop, as we all ride road bikes and xc trail bikes now…

I don’t think I was ever fitter, than when I was heavily into freeride and riding 40lb long-travel bikes.

I would not push up the hills, I would ride up the hills. I would commute on them. I would ride them everywhere. I built up serious muscle bulk, aerobic fitness and strength.

I went to Glentress for MBUK’s “Slopestyle Competition” and rode from my B&B in Peebles to the very top of the bike park on a Banshee Scream in Glentress carrying a full-face helmet, body armour and food / drink supplies, without breaking a sweat. And then spent 8 hours competing at the event.

look at this photo:

since stopping freeride? my XC trail bike weighs 24lbs, my road bike considerably lighter. Both are much easier to pedal and ride. Has my fitness decreased due to the lighter bikes? probably…

I am still having fun riding, and that it all that really matters to me :)

eshershoreFree MemberPosted 11 years agoI’ve run Specialixed Nimbus 700 x 28c on my 29’er no problem!

get the armadillo tire for puncture resistance and you are good to go, will even light off-road like fireroad and canal paths, or dry singletracks through the local woods

eshershoreFree MemberPosted 11 years agodon’t bother trying to fix it – the material has failed

speak to your local dealer (ideally who you bought the original saddle from) they should be able to sort something out at a reasonable cost

eshershoreFree MemberPosted 11 years agono love for the old design Chris King headset from me (

used to be ‘pressured’ to sell lots of them by one of my old employers, despite my concerns about my customer’s genuine concerns about creaking / clicking noises and scoring of their fork steerers

yes, I appreciated the ‘quality’ and high tolerances / precision of C.King’s aluminium-alloy cups and handbuilt bearings

however, their product was fundamentally flawed due to their refusal to license the Dia-Compe “Ahead-set” design which critically included the ‘compression wedge’ with sat under the top cap and prevented the headset loosing grip on the fork steerer once set to torque

this was not a UK specific issue, on vacation in Whistler, Canada; my riding buddy and I both had this issue with King headsets and the Marzocchi tech in the service truck at the bottom of the bike park expressed no surprise in finding 1.5mm deep grooves scored into our fork steerers by the constantly loosening King headset, he had seen it all before…

personally? I really tried to love both of the C.King threadless headsets I had bought at full retail price, but had nothing but trouble with them, creaking/clicking and always working loose

in comparison, the cheaper FSA, Dia Compe and Cane Creek headsets lasted me a good season or several seasons (depending on price point i.e. sealing and bearing quality) but gave NO problems with creaking/clicking or loosening, and no damage to the fork steerer, the only thing that would ruin those headsets would be eventual ingress of contaminants to the bearings

the new King headset, now that Dia Compe’s patent on the original ‘Aheadset’ expired? No idea??

….but hopefully it works properly now, as King’s bearings and manufacturing precision work was easily the best on the market

eshershoreFree MemberPosted 11 years agoused the BB mounted Superstar guide (which is also sold under M:Part and other “brand” names

its okay, but you can reset the chainguide lateral position by using finger pressure on the cage, which is not ideal. It now resides on my 1 x 10 commuting bike and does okay for that application.

I’ve also used the M:Part seat tube mounted guide (again the same as Superstar, etc.) its not as flimsy as the BB guide but certainly not as rigid as the E13 I replaced it with. With the M:Part I had several deraillments under heavy loads, with the E13 its been rock solid

E13 is expensive, but then chain devices are one of those items where its well worth paying more for quality, otherwise you compromise the function of the device which is to actually keep the chain in place///