- This topic has 255 replies, 41 voices, and was last updated 1 year ago by ditch_jockey.

-

Plunge sawyers, how are you getting on?

-

neilnevillFree MemberPosted 2 years ago

I had a Peter Millard video pop up on YouTube and I’ve been sucked in again. Found myself watching/rewatching all the tracksaw workshop and comparisons, including the new Macalister and parkside reviews, then a few other tracksaw reviews from skillbuild and others, then hours of googling and pricing up different options. I don’t even have a particular project at the moment, but I want plunge saw, daft. Anyway, I reread the tracksaw thread from a couple of years ago but that is now closed, so is it time for a new thread? How are the Titan and parkside users getting on? Tips, tricks, do’s and don’ts?

jefflFull MemberPosted 2 years agoI bought the MacAlister one a few weeks back, after watching the same Peter Millard videos. Primarily to cut down furniture board to finish off a kitchen. So skirting, end panels, a built in wine rack.

Overall really impressed. There is some chipping at the edges, so I may look at a finer pitched blade.

Took a few cuts to get my eye in so to speak. But other than that, all good.

Only negative is that it doesn’t have a soft start. So you need to ensure that you have some weight on the rails to stop them shifting.

Oh and the quantity of dust was significant, but I was working outside so not a great problem.

neilnevillFree MemberPosted 2 years agoDefinitely a blade upgrade seems worthwhile on the cheaper saws, and sound that from the off, before you trim the splinter guard.

BigJohnFull MemberPosted 2 years agoSome tips:

If you can’t get a clean cut, it’s not always the blade, it’s sometimes the material. I’ve got a bunch of blades, one cost as much as the Parkside saw, and some boards just chip for fun. If that happens I clamp the rail to the board and set the depth to 2mm and do a scoring cut first. If it’s the underneath that’s chipping experiment with the depth of cut. Some say the whole tooth should be visible, others say just 1mm is enough.Try to get some clamps that slide into the slot under the rail to hold it in place.

Make a cutting board with a piece at the back to rest your workpiece against and a couple of pieces at right angles to rest the rail against, helping to get square cuts without fuss. I even screwed part of a metre rule to the back “fence” so I could get accurate, repeat cuts.

See if you can get a kickback stop to clamp on the rail. If you start the cut with the saw backed up to the stop it prevents it jumping backwards if you plunge it into a board without sufficient pressure on the saw. That is a bit scary when it happens.

Rig up an old vacuum to the outlet to get maximum dust collection and always wear ear defenders.

neilnevillFree MemberPosted 2 years agoCrosscut board, Peter Millard shows how to make one, tbh I wasn’t sure it would be that useful but seems I should rethink. He shows how to make a set of parallel cut jigs and a rail square too

neilnevillFree MemberPosted 2 years agoAs for kickback, maybe I’ve been lucky but in 20+ years using a circular saw I’ve not had a bad kick. Ok it has a riving knife but it’s thinner than the blade. I recently rip cut an old piece of 2*4 that had so much tension the cut was closing and the saw struggling as the blade for clamped, but it didn’t kick. I’ve abused it plunging it to cross cut floor boards and been fine. I do tend to treat all power tools with respect and hold them firmly though.

dyna-tiFull MemberPosted 2 years ago. I’ve abused it plunging it to cross cut floor boards and been fine.

I wouldn’t say thats abusing it, it’s one of the saws primary functions to plunge cut, be it rip or crosscut.

On the subject of plunge cuts. I’ve always found it a bit of a worry having to use one hand to hold the spring guard open, I think some arrangement of operating the guard with the thumb on your trigger hand would be far safer. Even sometimes when starting on a board in a regular cut, sometimes the guard doesn’t want to roll open, and you’ve got to take one hand off to lift it a little bit. Always seemed the bad idea about circular saw spring guards.

neilnevillFree MemberPosted 2 years agoI know what your mean about the guards.

To my mind, plunging with a circular saw means starting the cut with only the toe of the base plate on the work piece is not what it was designed for, hence ‘abuse’. Miss use probably more accurate though.

phil5556Full MemberPosted 2 years agoI bought a Makita last year to build my campervan with. I felt like a pro using it 😁

I don’t know what track comes with what you’re looking at but I know some of them (eg Evolution) come with short sections of track. I made sure I had 150cm track (x2) so that the majority of cuts just used a single section.

neilnevillFree MemberPosted 2 years agoI’m looking closest at the makita. Mafell and festool are very spendy. The Bosch is designed/made with mafell so I expect awesome but I can’t find cheap rails (Bosch use the mafell system I understand) it’s spendy too. The Makita isn’t cheap but I can find it with 2*1600 rails for £395. With some hunting, saw only here and rails elsewhere, joiners somewhere else, I can save enough for a set of the quick action clamps for the same total.

The Macalister comes in a little over half that after a blade upgrade, an extra joiner, extra 1400 rail and clamps.jefflFull MemberPosted 2 years agoFrom what I understand the MacAlister uses the same style of rail as Makita. So you could always go for that with the 1600 Makita rails.

I’ve only used the two 700 rails joined together a few times but I’ve not noticed a jump between rails.

One thing to remember is that your rails will need to be longer than the material you’re cutting. Sounds obvious but the plunge saw needs to be completely on the rail, front to back, to ensure its true. So you need at least half the length of the saw in the rail overhanging, if that makes sense.

@neilnevill If you’re anywhere near Chesterfield you’re welcome to borrow my cheap MacAlister to see if it will work for you, before spending on Makita.pk13Full MemberPosted 2 years agoSo I was a non believer and for some uses they are just not a table saw replacement.

But thay do board cutting very well and hooked up to dust extractors they are a joy to use.

Being a sceptical bugger and due to dropping my Makita Rip saw and snapping the blade guard I popped to lidle and got the 50 quid saw swapped the blade for a proper one I had in another saw and it’s a very useful too.Top tips

Big roofing square for quick set up the yellow Stanley one from toolstation is great.

I don’t think it will rip timber down when I have a table saw to carry out that task it’s more an MDF/plywood cutting tool for me.

Having said that I should have got one years ago and they are far far safer than a skill saw.

Overall they are great .One thing I did was get the cheap evolution track with the slide in clamps

neilnevillFree MemberPosted 2 years agoYes makes be sense.

Ta, South London though. Tbh I’ve no idea why I’m looking past the MacAlister as Peter Millard rates it. Generally with tools I’ll buy a mix, tools I use lots I buy decent…DeWalt, Bosch, Makita. Tools I’m to use once or twice or I’m not sure about, I’ll buy cheap first. I guess I think I’d use the plunge saw lots, although with no project on the go at the moment, and 3 small kids consuming my time, i can’t be sure.Oh and the anti tip lip on the Makita rails foul the Macalister saw… Or was it the parkside… One of them.

skink2020Full MemberPosted 2 years agoI bought a Makita about two years ago. Best power tool I’ve ever bought. I think it was £325 with two 1500mm rails.

I’m a picture framer and by god, it’s been incredibly useful for making boxes for framing all sorts of memorabilia.

Stock blade is amazing on birch ply, MDT, shite ply, osb.

A dust producing monster mind you.simon_gFull MemberPosted 2 years agoI’ve got the Makita cordless and love it. Table saw is relegated to the few things it’s better for, mostly it’s become extra bench space.

I got a cheap MFT style top and some bench dogs. Also chopped a spare rail down to 800/600. Now makes it absurdly easy to get perfectly square cuts for shelves, cabinets, etc even in a small awkward single garage.

I’m just a DIYer not something I use professionally every day. Being able to cut quickly, accurately and square just makes everything else way easier.

kayak23Full MemberPosted 2 years agoI’ve got the Makita cordless and love it.

Me too. It’s a fantastic tool.

I use a table saw too for repeatability but I always use my track saw initially to break down panels and for where I want a really clean cut.The Makita has a scoring button so you do one pass with that on at a shallow depth, then go back full depth. The anti-fall onto the floor at 45 degrees button is brilliant too.

I think for diy use,a lot of those ones Peter Millard suggests would be great and infinitely better and safer than most diy approaches.

That white furniture board is bloody horrible stuff to try and cut nicely. I’d echo what BigJohn says above. Take a very light depth scoring cut before cutting through, make the cut very slowly too. Another thing you can do if it’s an important cut is to stick masking tape down on the cut line making sure it’s rubbed down well with no creases.

When you remove it, do it very slowly at a low angle towards the cut edge.Track saws are a revelation.

nickjbFree MemberPosted 2 years agoLove mine. Use it for all sorts of different cuts. Definitely don’t miss having a table saw. You can make up jigs for quick, repeatable, accurate cuts. Feels safe too.

Only issue is the price of longer track. Joined track is adequate but not mm perfect. None of the cheaper suppliers make longer track and the festool 2.8m is about 5x the price of the 1.4m

bridgesFree MemberPosted 2 years agoI took the plunge (!) and bought a Festool kit. Expensive (a few years ago, so nowhere near current insane prices!), but it’s such a nice tool to use; smooth, not too noisy, and dust extraction is fantastic. It feels much more solid and stable than other brands I’ve tried. Virtually no splintering, even with melamine faced boards etc, although it’s advisable to use a sacrificial sheet of MDF, underneath, to help alleviate this anyway. There is so little work to be done, following a cut. In terms of value for money, it’s been brilliant, despite the relatively very high initial cost. But because I know what a good tool it is, I end up using it a lot more than if it wasn’t so clean and accurate. So that only adds value. I’m not saying everyone should go out and buy a Festool, just sharing my own experience.

neilnevillFree MemberPosted 2 years agoAh yes of course! The sacrificial board would help reduce splintering I can see, so much better to do than supporting the work over an edge or something if you really need clean cuts. I’ve heard the making tape truck before too.

Don’t have a table saw bit might be tempted to make a jig to mount the, largely reductant, circular saw in for such purpose.

How useful is the anti tip lip on the Makita? Hmmm, they depends how often you do bevel cuts, d’oh! I realised I could get 2*1.4m of evolution track, plus the joiners, for £75, almost £50 less than the same Makita. I need to check but I think the Makita saw will run on the evolution track.

I’ve started creating projects to do….I need some folding doors….. Nothing like going straight in with a tricky job!

BigJohnFull MemberPosted 2 years agoI’ve got the Evolution 2×1400 pack. The whole thing, including bag costs less than the Festool bag! And you can fit 3 rails in it. Peter Millard did a video on rail/saw compatibility a few months back.

The clamps that it comes with need to go straight in the bin though. It works fine with my Festool saw but the splinter guard isn’t great. Tip – use Makita splinter guard on all your rails – cheaper than Festool and because it’s black it’s easier to position on the line.

As far as accuracy, mine is spot on. But I do line it up with my Festool 1400 back to back when tightening the grub screws. After that though I can move it on and off workpieces without it going wonky.

Oh, and referencing one of the posts above don’t try plunging a regular circular saw unless you want to be in Sarah Storey’s team.

And while we’re on circular saws, you can make them as good as expensive rail saws by making a simple fence out of some lengths of chipboard.footflapsFull MemberPosted 2 years agoI’ve been using the Bosch track saw, as a plunge saw, for years, although finally took the ‘plunge’ and bought the Mafell plunge saw kit earlier this year – they both share the same track system.

I pretty much always cut on a sacrificial sheet of ply (on tressles) to minimise break out on the underside edge.

[url=https://flic.kr/p/2m9uzWD]Untitled[/url] by Ben Freeman, on Flickr

kayak23Full MemberPosted 2 years agoThe thing with track saws is, in theory, they don’t necessarily need a sacrificial board underneath as the blade is cutting upwards from underneath and on top the strip supports the cut. More so if you do a scoring cut first

It can help though fo shiz, especially with furniture board horribleness.

footflapsFull MemberPosted 2 years agoas the blade is cutting upwards from underneath

But hasn’t it had to go down through the material in order to then come back up?

Actually another reason I started using the under board was dust collection, it stops the saw throwing sawdust under the table, the finer stuff of which then circulates in the air etc.

kayak23Full MemberPosted 2 years agoYes, if you’re starting inwards of the edges.

The majority of cuts would likely start outside, pass through and end outside.Actually another reason I started using the under board was dust collection, it stops the saw throwing sawdust under the table,

Good point 👍

djamboFree MemberPosted 2 years agoI did similar…binged Millard then bought a Titan about 18 months ago without a specific project in mind. Since then i’ve built a coffee table, bathroom shelf unit, doors for a TV unit, various shelves and the biggest to date a built in wardrobe/storage cupboard.

It’s fine for my needs. Some minor tear out on ply wood but nothing that makes me want to upgrade the blade based on what i’m doing with it.

I ended up buying a mft style top on ebay which came with 6 bench dogs. It’s just screwed to my old kitchen worktop ‘workbench’ in the garage. It makes getting square cuts on small/medium very easy. Well worth the money i paid for it (£50 or so from memory).

I also recently bought a titan shop vack which is great for keeping the dust down – i should have bought it earlier.

Watch out for kickback and always keep an eye on where the power lead is before you make a cut (so it doens’t snag, not just chopping through it!).

footflapsFull MemberPosted 2 years agoso it doens’t snag

I use a Festool Midi vacuum with my saws and their hose is ribbed which means it catches on everything. Fine of you can hang it from the ceiling, but if you’re using it connected to the vacuum on the floor, it’s a PITA and endlessly pulls out of the tool when it catches on the end of the workpiece.

I ended up buying a mft style top on ebay which came with 6 bench dogs. It’s just screwed to my old kitchen worktop ‘workbench’ in the garage. It makes getting square cuts on small/medium very easy. Well worth the money i paid for it (£50 or so from memory).

I made a DIY MFT table, based on one Scott Brown made. Not that accurate, but not bad for a first pass.

[url=https://flic.kr/p/2koeHYn]DIY MFT Table[/url] by Ben Freeman, on Flickr

[url=https://flic.kr/p/2m9ADbD]DIY MFT Table[/url] by Ben Freeman, on Flickr

Think that was the first pass, it was too deep so I remade all the sides about half the height.

neilnevillFree MemberPosted 2 years agookay, I’m in! new makita6000J appeared on ebay at £249 so I jumped. 1% topcashback and 0.5% nectar points. excel 3m rail set (2×1.5m plus joiners) as they are exact copies of makita with the antitip lip £94 on manomano with 8% topcashback from that, pair of makita rail clamps from dwtools for £20 delivered. So all set for a few pence unde £352.

I’ll be getting some mdf and building a crosscut jig and a set of parallel cut rails. but first…what was it…roofers square?

maccruiskeenFull MemberPosted 2 years agoroofers square?

Yes the big yellow plastic Stanley ones from Toolstation – nice thick edge to them so you can but the rail up against it

maccruiskeenFull MemberPosted 2 years agobased on one Scott Brown made.

Ron Paulk would be turning in his grave if he was dead. 🙂

footflapsFull MemberPosted 2 years agoRon Paulk would be turning in his grave if he was dead

I think Scott did mention him as being the original source, but never seen one of his videos.

roofers square?

Benchdogs do a nice one for MFT tables:

https://benchdogs.co.uk/collections/precision-triangle/products/precision-triangle-bd450pt

I’ve also got their rail square for my Bosch rails:

Axminster do an MFT one as well

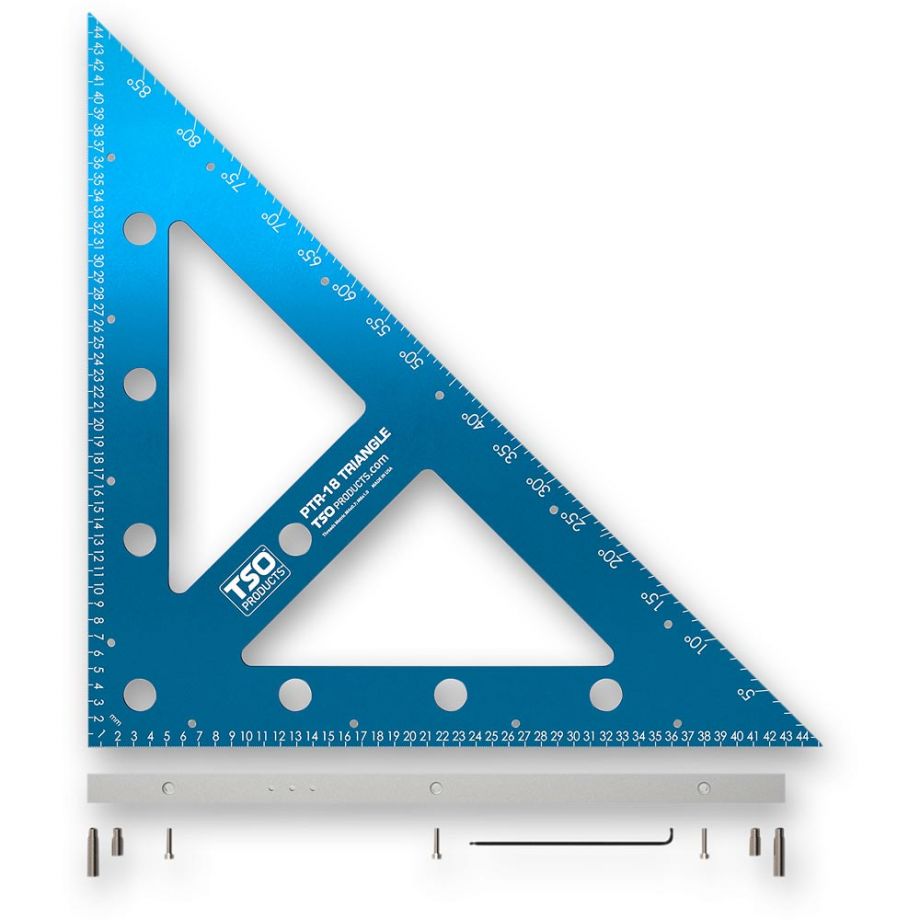

https://www.axminstertools.com/tso-products-ptr-18-plus-precision-basic-triangle-106357

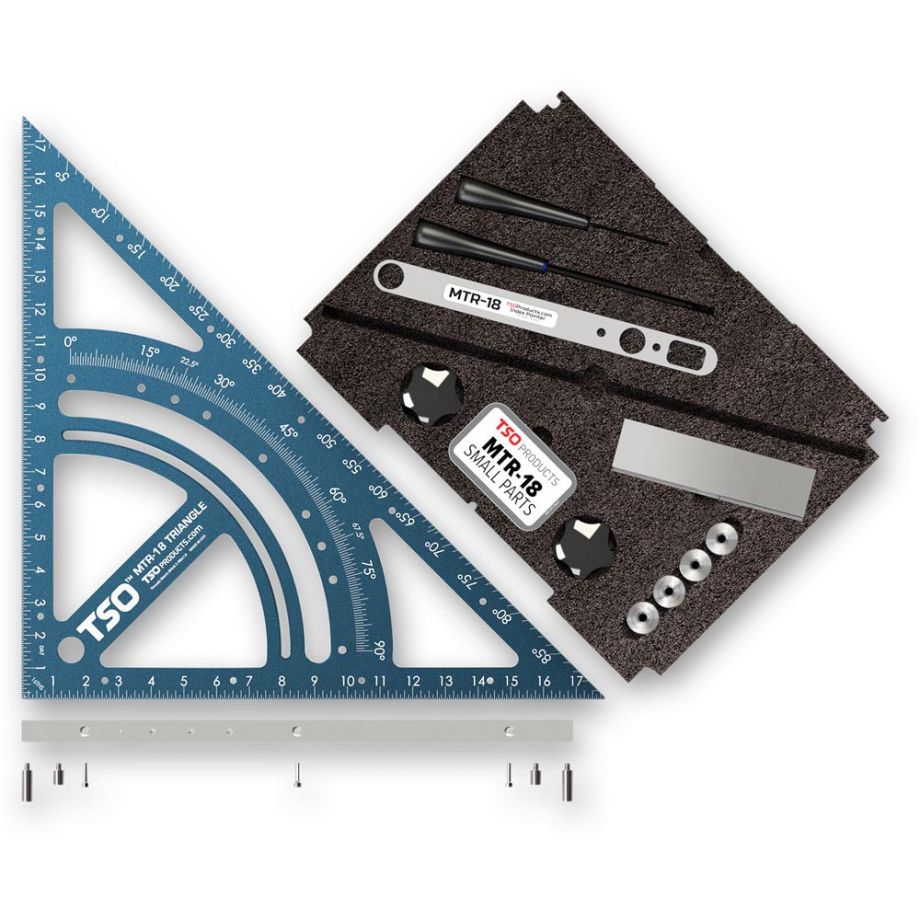

and an even more expensive one!

https://www.axminstertools.com/tso-products-mtr-18-precision-triangle-105204

footflapsFull MemberPosted 2 years agoActually I lied, the Benchdogs rail square was out of stock, mine was from FC Tools.

neilnevillFree MemberPosted 2 years agothe stanley isn’t square according to some amazon reviews (and pics), so a paid a little bit more and bought the swanson 12″ +7″ twin pack, £25.

BigJohnFull MemberPosted 2 years agoIf you want a square, don’t bother paying loadsamonney on a metal one. My view is that if you’re making furniture your tolerance is about .5mm. so go to b&q and buy a kitchen door. That’s square. Chop it up to make it lighter, add a bit to one edge to make an upstand and it will give you accurate cuts for years. That’s what I use, and I’ve got nothing against Benchdogs, I spend quite a lot with them, but squares are overrated.

And the “Spinning in his grave if he was still alive” gag was mine on another thread.burko73Full MemberPosted 2 years agoFascinating thread, watching with interest as I’ve also been watching Peter Millard and considering a track saw for home hobby use. Got some kick boards to make for redoing our kitchen and am always struggling with decent accurate long cuts with a circular saw. I have a load of Mikita lxt stuff so am tempted by their tracksaw despite it being more than I need.

Some reviews said the triton one was good re track etc but the saw wasn’t a true plunge saw, more of a circular saw that ran on track.

footflapsFull MemberPosted 2 years agoGot some kick boards to make for redoing our kitchen and am always struggling with decent accurate long cuts with a circular saw.

Track saw is a revelation, anyone can cut 2m with less tham 1mm error using one. Previous to getting my old Bosch one I was using a jigsaw against a metal edge clamped to the work, night and day difference! Track saws are just amazing for perfect straight edges.

bridgesFree MemberPosted 2 years agoThese are good for that.

HoseWraps

An old MTB innertube is just as effective, yet much, much cheaper.

footflapsFull MemberPosted 2 years agoAn old MTB innertube is just as effective, yet much, much cheaper.

Yes, but part of the fun of it all is having an excuse to buy nice tools. I have far better tools than I’ll ever be able to use at cabinetry!

bridgesFree MemberPosted 2 years agoLol! True, true. Although I do use pretty much everything I buy. Because I often realise that I need a particular type of tool, when doing a job where such a tool would be really bloody useful. I then buy said tool (often once I’ve actually completed said job the hard way), where it then lies for a while before being pushed into service. Things do get used though, I’m not a hipster. Side rebate plane; there you go. Such a useful, simple tool. Bloody none in stock at the moment though. 🙁

You must be logged in to reply to this topic.