- This topic has 26 replies, 20 voices, and was last updated 8 years ago by surroundedbyhills.

-

Mancave – workbench idea…

-

ir_banditoFree MemberPosted 8 years ago

I’ve just put a couple of steel-framed workbenches in my garage, like this:

The seem sturdy enough, but the worksurface is a bit flimsy. I’m wondering about putting a 2.4m length of 18mm chipboard flooring over the top:

http://www.wickes.co.uk/Wickes-P5-T+G-Chipboard-Flooring-18x600x2400mm/p/164516Any reason not to? Ideally I’d find a perfect length of 38mm kitchen worktop going spare, but thats not likely.

alpinFree MemberPosted 8 years agobecause chipboad will swell up over time if left out in a garage. better off looking at a solid lump of marine ply or multiplex…

scotroutesFull MemberPosted 8 years agoI’ve got one of them in my garage too. The worksurface isn’t what I’d call flimsy – though I guess it depends what you’re planning to do on it. You’d obviously want to reinforce any area where you’d be fitting a vice.

projectFree MemberPosted 8 years agoUse 25 mm mdf and cover with a piece of hardboard, dimple side up, stops stuff rolling away also an just be lifted off when covered in oil use double sided tape tp secure or gaffer tape folded double.

muppet4Free MemberPosted 8 years agoIf your Cambridgeshire way I can easily get hold of a worktop, what I have used in my workshop for ages and it does the job fine.

piemonsterFull MemberPosted 8 years ago+1 for ply

I also have a square of OSB which doubles up as a drill press mounting board and general whacking area.

Not elegant, but effective.

maccruiskeenFull MemberPosted 8 years agobecause chipboad will swell up over time if left out in a garage. better off looking at a solid lump of marine ply or multiplex…

Chipboard flooring boards won’t swell unless you’re workshop is swamp, they’re moisture resistant . The floor in my workshop are still fine even though the roof leaks and the whole floor spent a weekend under 6″ or water last year. For extra burl you can get 22mm boards too

footflapsFull MemberPosted 8 years agoBrace the top with a few lengths of 2×4″ underneath to reduce flex?

senorjFull MemberPosted 8 years agoMarine ply rather than bare chipboard.

Cheapo kitchen worktop is what’s in my shed at moment,sealed the rear and it’s fine after 18 month.

Edit ,waves at br.xxmaccruiskeenFull MemberPosted 8 years agoMarine ply rather than bare chipboard.

Why marine ply?- are you planning to sail your workbench and require Lloyds of London to underwrite you? 🙂 Theres nothing that plywood is going to bring to the party that chipboard isn’t going to do more than well enough and given that ply is sold in widths twice as wide as the OP is looking for he’ll have twice as he wants for more than 5 times the price.

A bit of chipboard flooring (not just plain 8×4 chipboard sheets- thats a different grade) will be fine, a bit of worktop will be fine but unless someone has an off cut they are sold in huge lengths (although Ikea 25mm beach stave worktops are cheap and sold in short enough lengths incidentally). The main difference between chip flooring and 38mm worktops will be one is matt and grippy and the other is slick and slippery – its easier to get stuff to stay put on chipboard – not least by just screwing stuff down, formica / melamine kitchen worktop is better if you work with anything oily, wet or solvent-y that you want to be able to clean up easily.

senorjFull MemberPosted 8 years agoI beg your pardon.i meant waterproof/treated,so sorry. Forgive me ,please?

ir_banditoFree MemberPosted 8 years agoThe loft in the garage is boarded out with chipboard flooring, and that’s ok, so should be fine.

Not a bad mess for 24 hours use 🙂

they are sold in huge lengths

I need 2.4m to cover both benches

isn’t what I’d call flimsy – though I guess it depends what you’re planning to do on it.

See the Axminster mini milling-machine on the windowsill? Its hefty enough to bend the present benchtop when I put it on.

maccruiskeenFull MemberPosted 8 years agoSee the Axminster mini milling-machine on the windowsill? Its hefty enough to bend the present benchtop when I put it on.

I’d expect that the 18mm you linked to in the OP, over the top of the existing surface would be plenty, but theres hardly any extra to pay for 22mm if anywhere local to you stocks it. However another solution would be to sit the mill on a couple of chucky planks that span between the top rails of the bench so that the weight spread to them rather than tries to sag the worktop in the middle – particularly if you want the mill to sit there long term.

andylFree MemberPosted 8 years agoChipboard flooring will be harder than ply when smacked with stuff. I laid a waterproof (greenish tint) t&g chipboard door in my workshop and coated it with lots of screwfix no nonsense water based pu lacquer and its survived lots. Only damage I did was when refitting after me oving it when I caught a few edges but the edges are the weak point with chipboard. Ply is much better in that respect. You could edge/frame it with some planed timber of the same thickness which would work well and be replaceable and kind to anything knocked against it unlike metal.

ir_banditoFree MemberPosted 8 years agoIts not bad.

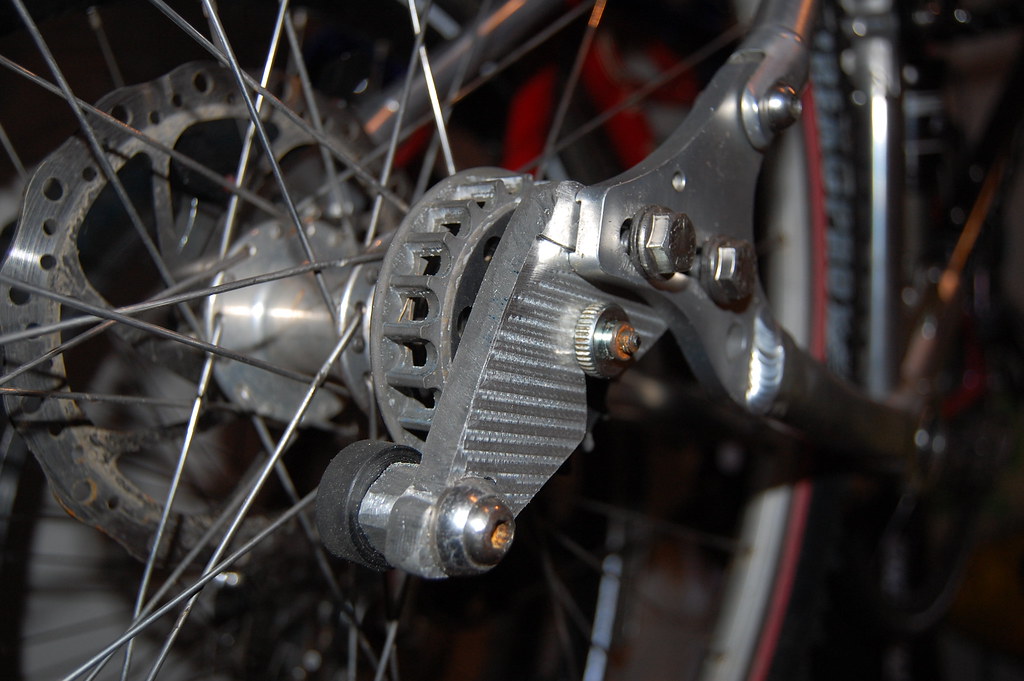

Only used it a few times for making dropouts when I was experimenting with my belt-drive bike.

[url=https://flic.kr/p/9n7hL6]DSC_0405[/url] by ir_bandito, on Flickr

(hand-profiled, faced on the mill)

I aaquired it from my previous employer. Ahem. Only used it a few times as I didn’t have the space to set it up in my old house. Now I have the bench in the garage, I want to use it more. Except I now have a Minitech GX4 to play with at work….TurnerGuyFree MemberPosted 8 years agoThe back legs have holes in so make some spacers to the wall and bolt it to the wall behind. Did that with some similar construction shelves and they are rock solid.

petefromearthFull MemberPosted 8 years agoIf you do use a bit of chipboard/formica kitchen worktop it’s worth thinking about the colour. Dark colours (eg granite effect) can make it harder to see small metal bits and bobs when you put them down. Mate of mine was forever losing things right under his nose!

maccruiskeenFull MemberPosted 8 years agoDark colours (eg granite effect) can make it harder to see small metal bits and bobs when you put them down.

Just turn it upside down – they’re usually beige underneath, not quite as hardwearing a surface though.

WorldClassAccidentFree MemberPosted 8 years agoI have some similar shelves (right of pic) and they are quite flimsy and not up to proper work bench use. Having said that I put a bit of old kitchen work top over them and it is kind of okay

TurnerGuyFree MemberPosted 8 years agoI have some similar shelves (right of pic) and they are quite flimsy

that’s the type of shelving I have and I have bolted them to the wall plus have them 2 levels deep and they are really solid…

johndohFree MemberPosted 8 years agoI did exactly what the OP asked about two years ago and I haven’t experienced any issues at all.

surroundedbyhillsFree MemberPosted 8 years agoI’ve just had to chuck out the MDF shelves from my racks and workbench due to mould, was thinking about replacing with ply.

But you say chipboard is good enough? is it much cheaper? OSB2 good enough

I live in Dunblane atmos conditions are damp for long periods – Timber garage which has some ventilation over the windows..

The topic ‘Mancave – workbench idea…’ is closed to new replies.