- This topic has 67 replies, 37 voices, and was last updated 13 years ago by MountainMutant.

-

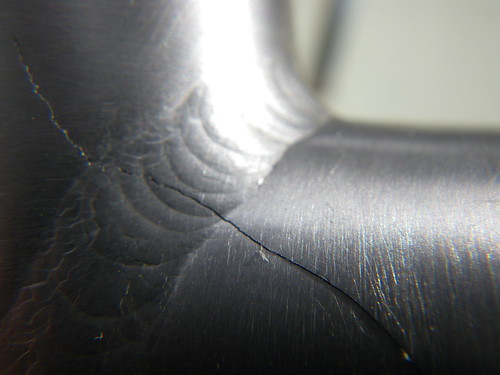

Cracked Titanium frame

-

jamesbFree MemberPosted 13 years ago

didn`t manage to post pic……to join gallery of Ti cracked welds etc!

brantFree MemberPosted 13 years agoLooks a lot like the sort of thing that happens with very thin (too thin a) wall thickness. The reason for butted tubes is to have enough thickness of metal to avoid this type of failure.

All the examples of butted ti I’ve seen are the same thickness as PG frames at the end, and *even thinner* in the middle. Not thicker at the ends (as it were).

GruenermoenchFree MemberPosted 13 years agoIf COTIC built their frames using a 35mm seat tube and a 30.9mm seat post insert then I very much doubt that this frame would have failed in the way that it did. Another possibility is that the top tube and seat tube wern’t mitred together very well(formed so they fit together properly without a gap)creating a weakness at that joint. That said the ti tubing might not be up to the same standards as the stuff that Lynskey probably use. I’ve never heard of one of their frames failing and they must knock out thousands each year.

wwaswasFull MemberPosted 13 years agomight not be up to the same standards as the stuff that Lynskey probably use. I’ve never heard of one of their frames failing

the Ti 456 dropout photo will be along shortly…

scruffFree MemberPosted 13 years agoJust to add some fairness, I have cracked a Ti frame that wasnt the same manufacturer as the OP’s. Mine was out of warranty but was still replaced by a (lower spec) frame FOC, I was happy with that.

GruenermoenchFree MemberPosted 13 years agothe Ti 456 dropout photo will be along shortly…

???????????

WallyFull MemberPosted 13 years agoMM very sorry to see this, it would be ironic to hear the old rock lobster Ti is still going strong. Epping was lovely last week – expecting a mud bath this week. Post up the conclusion.

MountainMutantFree MemberPosted 13 years agoHey, glad you are still enjoying it 🙂

Epping was surprisingly dry last weekend! Hopefully have some news on the bike next week

MM

MacavityFree MemberPosted 13 years ago“All the examples of butted ti I’ve seen are the same thickness as PG frames at the end, and *even thinner* in the middle. Not thicker at the ends (as it were). “

Until some one cuts too much off the end of a butted tube (to make a smaller frame) and then, they are onto the thinner middle section of the tube. Which it looks very much like in the picture from Elliptic.MacavityFree MemberPosted 13 years agoTitanium (titanium Alloys) can be subject to stress corrosion cracking (SCC)when exposed to alcohol (propanol).

This is similar to the effects of hydrogen embrittlement, and the effect of SCC from ammonia on brass, chlorine-ions on some stainless-steels.wwaswasFull MemberPosted 13 years agoalthough this example does look like weld not material failure.

cynic-alFree MemberPosted 13 years agoMacavity – Member

“All the examples of butted ti I’ve seen are the same thickness as PG frames at the end, and *even thinner* in the middle. Not thicker at the ends (as it were). “

Until some one cuts too much off the end of a butted tube (to make a smaller frame) and then, they are onto the thinner middle section of the tube. Which it looks very much like in the picture from Elliptic.You have x-ray vision? There’s a stress riser there and we know nothing about how the bike was used vs its intended use!

horaFree MemberPosted 13 years agoI wouldn’t repair it.

I’d expect a like for like replacement.

Too much seatpost? How tall are you and what size is the frame? If your 6f2 and running a 16″ they could reasonably argue there…if its a 19″ and 6ft2 for instance then you can say ‘more impossible/why would I need to’On a side-note, one of the ti frames shown on this thread- I found mine had a lot of flex and the reviewers love the frame for its ability to ‘soak up the trail’ on the DH’s? Surely a candidate for a premature-end with all that ‘flexing’ etc going on around the welds etc putting stress through them?

cynic-alFree MemberPosted 13 years agoHora they could also say “the frame was sold with a 4 year 50% off warranty” 😐

ellipticFree MemberPosted 13 years agoUntil some one cuts too much off the end of a butted tube (to make a smaller frame) and then, they are onto the thinner middle section of the tube. Which it looks very much like in the picture from Elliptic.

That had occurred to me also. My frame is (was) the “small” size with the mitred weld between the top and down tubes (on the medium/large sizes they don’t touch and there’s a short gusset under the top tube instead). So if the tip of the weld reaches the thin part of the tube..? just speculation though.

we know nothing about how the bike was used vs its intended use!

Standard issue trail riding, for the two years I owned it at least. Nothing stupid. When it broke it was (genuinely) JRA on a day ride in the Lakes.

horaFree MemberPosted 13 years agoI always thought the percentage tend to apply to accidental/crash damage. 😐 Oh well!

ojomFree MemberPosted 13 years agoUntil some one cuts too much off the end of a butted tube (to make a smaller frame) and then, they are onto the thinner middle section of the tube. Which it looks very much like in the picture from Elliptic.

Many frames are butted per tube length. I.e. ‘small’ frame top tube will have proportional butting and so will a ‘large’ unique to the tube.

So this cutting off of the butt is extremely unlikely to be the case or norm.

MountainMutantFree MemberPosted 13 years agoMine is a LARGE frame with 4cm more seatpost in the frame than the warranty covers.

It shouldn’t of happened and pretty pissed off that a 4yr old xc frame should do this. At the moment looks like I am minimum £500 out of pocket.

MM

MacavityFree MemberPosted 13 years ago“So this cutting off of the butt is extremely unlikely to be the case or norm”

Sorry, its only the medical profession that makes basic errors.

http://www.dailymail.co.uk/news/article-1267451/Surgeon-cut-patients-testicle-mistake.html

http://www.nursingtimes.net/whats-new-in-nursing/news-topics/ethics-and-law-in-nursing/nurse-switched-off-life-support/5020874.articleMacavityFree MemberPosted 13 years agoIn the OP there is a picture of a cold cracking toe crack at the edge of a concave weld.

In the Elliptic picture (good picture) there is not just a crack but the edges of the crack can be seen to have been deformed outwards.

This looks very much like the result of movement (resulting from the crack) / impacting of the two side of the crack together and, a very thin wall thickness crumpling / deforming on contact with the opposing side of the crack.jambonFree MemberPosted 13 years agoThis may have no relivance (sp) at all, but I cracked two aliminium frames and a steel frame, in exactly the same area and blamed the frame each time for the problem. After all this carnage I realised that the seat-post I’d been using all that time flexed back about an inch when I sat on is. It seemd as though the seat-post was the culprit in the end, not the frames.

J

vorsprungFree MemberPosted 13 years agoSame Story here. I am going to get it welded, probably by Enigma. However the thing is that if it cracks once like this it’s a sign that the tubing welds on the whole frame are somewhat dubious. So my best long distance frame is going to get downgraded to a single speed pub bike 🙂

MacavityFree MemberPosted 13 years agoIn the photo from StirlingCrispin the horrible cut-finish suggests a laser-cut surface.

http://www.thefabricator.com/article/lasercutting/the-challenges-of-laser-cutting-overcoming-some-common-obstacles“Laser cutting can leave a recast layer on the surface. Because lasers melt and burn some of the metal, remelted materials are deposited on the side of the cut edges and on the bottom of the cut. This layer of deposited materials is highly stressed and may crack, especially if it is an oxide. Although these cracks are small, they can propagate into the material, creating larger cracks. This is especially true of inside corners with small radii, where stresses are higher.

Cracks can be eliminated in certain cases with high-pressure nitrogen cutting. For example, titanium is extremely reactive to oxygen. Oxygen embrittlement can lead to micro-cracks, which are an important safety concern for users of titanium such as the aerospace and medical industries, in which long-term strength and avoiding fatigue cracks is critical. Using high-pressure nitrogen is often the solution. This method effectively turns the laser into a controlled welding machine, blowing molten material away with 160 pounds per square inch (PSI) gas.

”MacavityFree MemberPosted 13 years agoIn the picture from vorsprung it is interesting to see the difference in appearance between the same crack on one tube and on the other tube. On the right (of the picture) it is fairly / relatively direct / straight (as cracks go), but on the left it is more erratic and meandering.

Different thicknesses of tube? Maybe, maybe not.MountainMutantFree MemberPosted 13 years agoSo my insurance company have got back to me and offered a 2011 Cove Hummer frame as replacement.

I could probably push for cash and get another Soda but tempted by the Hummer.

Anyone ridden both to compare? I do like the Soda geometry. It fits me well.

MM

The topic ‘Cracked Titanium frame’ is closed to new replies.