- This topic has 66 replies, 23 voices, and was last updated 10 years ago by emanuel.

-

Anyone tried making their own steel frame?

-

chunkymonkey1982Free MemberPosted 10 years ago

Hello,

Anyone tried to make their own bike frame? I really want to make my own steel 29er frame. I have a lathe, milling machine, MIG welder, and a load of basic tools, and know how to use Autodesk Inventor.

Is this a bad idea? What are the pitfalls? It cant be that hard….. right?

Any helpful links? I keep finding links for homemade carbon frames, not much on steel ones…

Chunky

OllyFree MemberPosted 10 years agoIve not done it, but lets be honest. There isnt THAT much to it. (im sure it takes a lot of skill to make a really nice fraqme) Welding thin Reynolds you will have to be super careful not to blow through the tube, but i reckon if you stick with on-one grade steel you’ll be reet!

Get a big sheet of nice thick Ply to build your Jig off and give it a go.

measure twice, cut once etc etc

Worst case scenario it snaps on you, meh.

your first will be a bit shonky, and maybe wonkey but whats the harm in trying?Check this out:

mick_rFull MemberPosted 10 years agoMTBR framebuiding forum is your friend. Read everything.

Then read some more.

Practice joints with tubes from old frames

Ceeway in UK for Columbus tubes or direct from Reynolds. Columbus Gara cro-mo tubes are cheap and plenty strong enough for playing with (about £12 for 1.5m lengths).

Maybe forget the MIG welder for any tubes under 1mm thick – TIG or braze is the way to go.

If you want to go crude and dirty with MIG and thicker tubes (old bike frames and ERW tube etc) then check out Atomic Zombie website. But you don’t want to do that 🙂

Edric64Free MemberPosted 10 years agoSuzy Jackson of Littlefish is a self taught frame builder and has an interesting website and blog

maximusmountainFree MemberPosted 10 years agoBrazing is strong enough for mtb? I may have to give this a go then. Mainly commenting to bookmark this for later.

edit: my main concern has always been the chain and seat stays, they look difficult to do.

jonm81Full MemberPosted 10 years agoChances are you will blow holes in the thin frame tubing using MIG. Most MIG sets dont have a low enough amps setting for thin wall tubing.

Other than that, go for it. It is very satisfying riding a bike you have made.

Check out the forums at Velocipedesalon for lots of info on steel frame building using both fillet brazing and TIG.

Stayhigh, I am pretty sure you need to be a member of Sketchymtb to view threads on there now.

OllyFree MemberPosted 10 years agobrazing is how lugged bikes are made. the lugs tend to be cast.

because old style road bikes dont vary toooooo much, the lugs can be standard castings, and the geometry is changed purely by changing the length of the tubes. (and a little play in the lugs)

you could braze a mountain bike, but you would be limited as to which standard castings you could use. you would have to work out your own connections for many of the joints. it is possible to make your own lugs though (if a little labor intensive).

you could weld up the lug parts from thicker steel, grind them down to a nice finish, then braze finer tubes into them.brantFree MemberPosted 10 years agoWelding thin Reynolds you will have to be super careful not to blow through the tube, but i reckon if you stick with on-one grade steel you’ll be reet!

I think you don’t realise the differences.

On-one main tubes are butted, typically 1.0mm to 0.7mm or 0.9mm to 0.6mm thick.

The thinnest main tubes I would use on a mountainbike, with 853 are 0.8mm to 0.6mm, and the thinnest they make are 0.7mm to 0.5mm.

OllyFree MemberPosted 10 years agoin true keyboard warrior style, i certainly dont brant. No offence intended to on one!

alexdudleyFree MemberPosted 10 years agoIt’s not that difficult to build your own bike in steel of you have reasonable engineering skills, you could mig it but would need thicker tubes, so just like those £99 Chinese bikes. To build a bike that will last a long time and you would be proud to say you built it is much more difficult . The jig and joint cutting needs to be very precise or when you weld it up you are building in errors that then take a lot work and straining of the frame to correct. Give it a go, as mentioned on here ceeway will sell you the tubes and dropout etc. you will need to tig or fillet braze their tubes as even the plain gauge tube is 1.0 mm . You don’t need to be trade and you can phone up and talk to them for advise, probably only cost a little over £100.

ahwilesFree MemberPosted 10 years agoit’s a terrible idea, but it’s quite good fun, so crack on.

fillet brazing would allow you a little room for mistakes – it’s more than strong enough.

you’ll need a jig – you can buy them, but they’re not cheap. you can make you’re own, but that’s a trickier and more expensive job than making the frame.

(once you’ve made/bought a jig, making a frame is almost the easy bit)

It’s not that difficult to build your own bike in steel of you have reasonable

engineeringfabrication skillspoe82Free MemberPosted 10 years agoThe jig is always the part that’s put me off-too much time and money to do it right. Has anyone done this already (built the jig)? If anyone has, would they be happy to let some of us newbies borrow/use it?

mick_rFull MemberPosted 10 years agoOlly – brazing can be done without lugs and is plenty strong enough for any type of frame – from kids bikes to car chassis (arguably better in fatigue than any other joining method).

You don’t actually need a jig – some people just work from a flat surface. Jigs make things much easier, but it can be quite frustrating having to spend time making one before you even start on a frame (but time well spent). As a hobbyist, for tacking together seat stay sub assemblies I still use a big block of wood and nails.

Probably best not to start the engineer / fabricator debate 🙂

I started framebuilding to make things that couldn’t be bought – compared to buying an off the shelf frame it is pretty expensive / scary if you sit down and honestly add up EVERYTHING that you spend.

If you really want to do it then don’t get too obsessive about alignment – if it visually looks ok and the wheel sits central in the stays then it will ride just fine. More important to do a sound structural job. Mike Burrows famously says he has (deliberately) never made a frame where the front and back wheel are in line.

So come on then – of all the posters, what have we actually built? I’ll start with:-

Wooden unicycle

Folding bike – Reynolds 531 and plywood monocoque centre section

Kiddy carrying full suspension bike

E-stay rigid 29er ss (sub 16″ stays)

Hardtail 29er ss / geared (16.25″ stays)

Purgatory cyclocross bike (no seat tube / saddle)

Teenager balance bike

Older kid balance bike

Numerous repairs and dropout alterations, cable stop additions etc.Current projects are a CX frame for mrs and 26″ hardtail for youngest son’s next bike.

For originality and inspiration my favourite builder is Julie Racing Design. Gloriously bonkers frames, beautifully made by a really nice guy:-

http://julieracingdesig.canalblog.com/jonm81Full Memberpoe82Free MemberPosted 10 years agoOnly ever repaired really, a few commencal meta 5s with cracks around the shock mounts, my old giant atx 990dh with similar problems and my first proper bike an old tange diamond back frame. Add that to loads of motorbikes.

maximusmountainFree MemberPosted 10 years agoHow do you go about the drop outs? Do you buy the drop outs in or make them yourselves? Fillet brazing wouldnt be an issue for me (I can braze better than I can TIG).

Jonm81 – where did you get the materials from?

mick_rFull MemberPosted 10 years agoHopefully the guy that converts the aluminium tandems into full sus will be along soon – they were very tidy.

I make my own dropout designs – sometimes hand cut, but often profiled from a simple dxf cad file. A place I use for work does high definition plasma and it comes out around £4 a dropout including material – they have automatic nesting software so just include my bits and bobs to use up otherwise scrap bits when cutting bigger things from full sheets. One face is perfect, the other is a bit more ragged but nothing a file and powder coat don’t hide. Water jet is very clean. Lazer is somewhere in between. The material I use is the same as truck chassis crossmembers. Mild steel is a slightly lower yield strength but still fine – no need for cro-mo plate when the part is more than 5mm thick.

If brazing, think really hard about the dropout design and where / how you will heat. My first attempts were a nightmare where the cut edges of tube got cooked whilst trying to heat the thicker stuff.

Might dig out some photos later.

richmarsFull MemberPosted 10 years agoI reckon it’s easier to make one in carbon. Welding and brazing are real skills, while making a frame in carbon just requires the ability to mix the correct ratio of glue. I wish I could weld or braze, which is why I’ve made frames in carbon.

oliverracingFull MemberPosted 10 years agoI will agree with rich here – mixing a bit off resin and adding a bit of cloth is childs play 😉 – anyone can make a carbon frame… BUT the difficulty is getting a good carbon frame – most i’ve seen seem to be either very heavy, flexy or break – mine was not too bad but I spent over a year researching the layup and tube thicknesses – and I still have had to modify it to my liking (bottom of this unrelated post – clicky )

maxtorqueFull MemberPosted 10 years agoThing is, a badly joined steel frame is obviously badly joined generally speaking. A badly laid up Carbon one can look perfect on the outside……….

Even the “professionals” get it wrong, just witness the lack of gloves during lay up on the recent Alchemist Carbon wheels news story…………..

richmarsFull MemberPosted 10 years agoI guess it depends on what you’re trying to do. I wanted to make a frame. I wasn’t interested in making it as light as possible, just something that I could ride. In carbon, that means over-engineering everything, which is easy (you just add carbon). In steel, you still need to learn how to weld/braze, which isn’t impossible, but not easy without the kit or knowing someone how can help.

Whatever material, have a go!mick_rFull MemberPosted 10 years agoOP

Forgot to mention – I use Inventor at work. Modelling a frame is a bit of a faff – use bikecad if you are in a hurry. The easiest way on Inventor is to use framework tool, but faffy as you need to load up your own tube cross sections (not tried this myself). Also can’t print off tube mitre templates.

I did mine as an assembly of revolved tubes. Tubes done as sheet metal parts, sketch one wall cross section and a centreline, then revolve 359.9 degrees. Once all drawn up as a frame assembly, you can “unroll” the split tubes to allow printing of mitre templates (maybe not an issue if you already have a milling machine for cutting mitres using holesaws).

jonm81Full MemberPosted 10 years agoJonm81 – where did you get the materials from?

The jig material came from RS components. It is only 40×40 extruded aluminium. You could probably find them cheaper online.

I got a Nova Cycles 29er tubeset and the dropouts were from Paragon Machine Works. The frameset and dropouts are not too expensive but when you factor in import tax you would be cheaper to go to Ceeways.

All in you’re much cheaper buying a frame from almost any manufacturer.

For frame design, use RattleCAD. It is like bikeCAD only completely free.

bencooperFree MemberPosted 10 years agoEvery framebuilder made their first frame once – MIG isn’t really suitable, but TIG or fillet brazing are roughly equivalent in terms of steels you can use and choices of angles.

You can build completely without a jig – I learned using just a vice and string – but a simple jig can make life a lot less exasperating.

If you’re only going to make one frame for yourself, take your time and enjoy it – it won’t matter if it takes you ages to hand-miter one tube and file down brass filets. Better that than rushing and bodging it.

chunkymonkey1982Free MemberPosted 10 years agoWow, thanks everyone for responding. Lots of good information here… so… i’m going to do it, well at least have a go at making a frame. I want a steel 29er so that will be the aim. I will get myself a TIG DC welder on ebay, design a jig on inventor as it would be easy for me to do, and put a frame together on rattleCAD (thanks jonm81) to check dimensions. This will be a one off so dont intend to make jigs for mass production.

A few guys mentioned that they have made frames before, any pics?

I want to make something different, but i guess the first frame should be as simple as possible.

Thanks for the suggestions, advice all. I will put updates up here.

bencooperFree MemberPosted 10 years agoI want to make something different, but i guess the first frame should be as simple as possible.

As my previous comment – if it’s the only frame you plan to make, may as well go wild 😉

My first frame was a spaceframe long-wheelbase recumbent with swept-back forks…

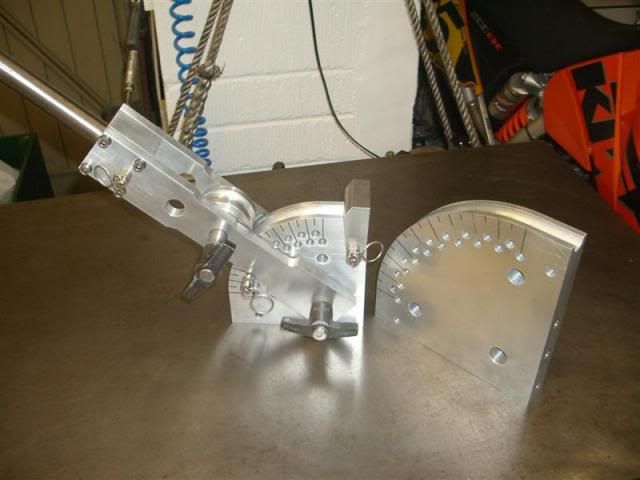

mick_rFull MemberPosted 10 years agoPile of photos. I’ve tried to pick ones that demonstrate things discussed above (and shonky ways of doing things for one-offs).

I’ve got an Inventor model of the jig – uses Bosch 60mm x 60mm extrusion that was heading for a skip.

Bending those e-stay chainstays was a real headache. Would have been even harder without using inventor to work out the exact angles / rotation of the tubes between each bend. The rear bend takes the tube both downwards and makes parallel to the dropouts in one hit if that makes any sense.

[img]https://lh5.googleusercontent.com/-z6uqAGLuAnw/UsXEVNRTY5I/AAAAAAAAAM0/cd_zy252_cg/s640/P1000822.JPG[/img]

chunkymonkey1982Free MemberPosted 10 years agoahwiles, that looks complicated, any close up pics of the pivots?

Mike R, Wow, that’s cool. How did you bend the pipe? was thinking of using the pipe benders used by plumbers on copper pipe, but not sure if its man enough to bend steel.

mick_rFull MemberPosted 10 years agoThanks guys – hope it helps your projects. My first frame stuff was back in 1994 and it was impossible to get any information back then – the internet has made things much easier.

Bending thin tubes is a real pain and mine aren’t perfect. There is no substitute for dies and tooling unfortunately. The 22mm stays were done with modified plumbing style benders (I tried to get them CNC bent but nowhere had the right size tooling).

Big radius bend in the seat tubes was even harder and used a home made plywood former, washing machine ballraces, a railway sleeper, scaffold tube, sand, ratchet straps and much effort 🙂

That suspension frame looks more interesting the more you look at it.

bencooperFree MemberPosted 10 years agoThis is true – I have several benders for different jobs, doing thin-wall tubes without crumpling isn’t cheap.

mick_rFull MemberPosted 10 years agoI know coppersmiths that can work wonders freehand hot bending using foundry sand and a gas torch (one did me a shower rail). Unfortunately hot bending will trash most quality frame tubes.

thomthumbFree MemberPosted 10 years agowelding is easy; (i’m crap and i could teach you in 20 minutes). getting good at welding takes a lot of practice.

citizenkaneFree Member

The topic ‘Anyone tried making their own steel frame?’ is closed to new replies.