- This topic has 30 replies, 23 voices, and was last updated 8 years ago by weeksy.

-

What wood for a workbench frame?

-

swdanFree MemberPosted 8 years ago

Morning everyone,

I did a search and couldn’t find anytjng but happy to be corrected by those in the know.

I have a 6′ length of kitchen work top which I would like to use as a workbench top. I therefore just need to make a frame.

I’m probably going for something fairly simple such as a 4×4 leg in each corner, braced with some 2×4 at the top and near the bottom and a thick Ply or MDF base that will also act as a shelf.

I’m not too worried about the looks as it’ll be a bit of a bodge anyway but they only wood I can find in 4×4 is fence posts. The advantage is that they’ll be treated and therefore slightly more resistant to the conditions in the garage, the downside is the finish will be a bit rough. Has anyone done this before? Were the posts alright or did you use something different?

The cheaper the better within reason although I still want something with some weight to it.

The look I’m going for is probably a simplified version of this without so much notching

how to make a work benchCheers

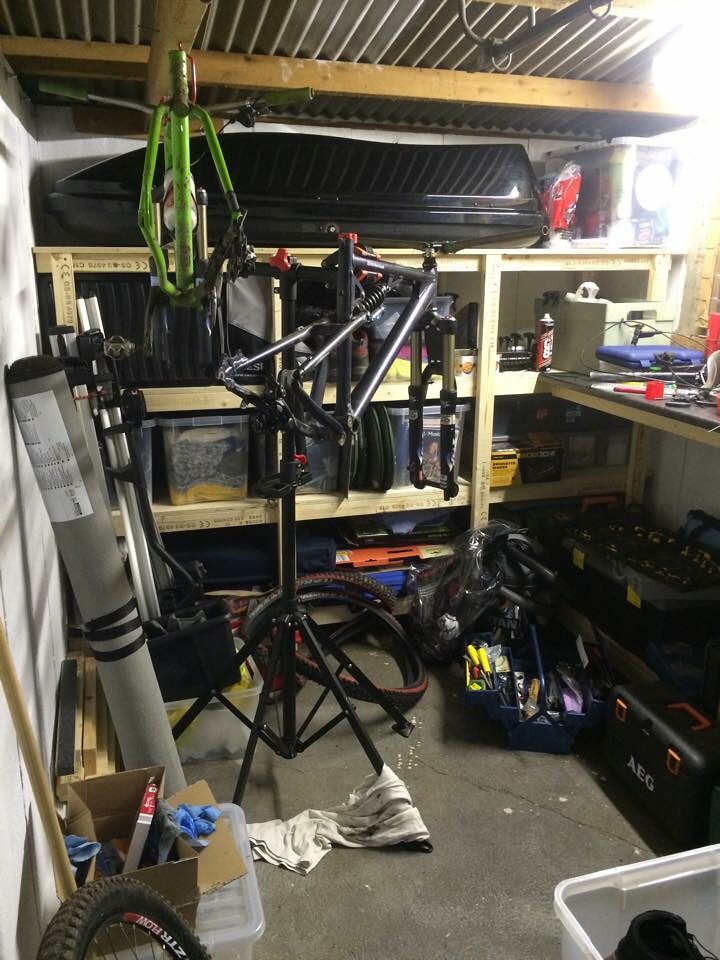

momoFull MemberPosted 8 years agoMine is made up of 3×2 with 18mm ply for shelves and a 38mm kitchen worktop as a bench. Not the best photo

[url=https://flic.kr/p/FNfcLq]Workshop[/url] by Matt Cotterill, on Flickr

daftvaderFree MemberPosted 8 years agoI just used studding from wickes for both my work benches… Couple of quid for a 2.8m length… Hth

Edit… They both have some hefty (60kg plus) machines on them so it’s perfectly strong enoughswdanFree MemberPosted 8 years agoYeah, I was wondering whether I was over engineering it. The reality of it is that it’ll be used for a bit of DIY and bike fettling and maybe the off bit if (beginners) woodwork once I get a vice to fit to one end. Like the idea tonsomerhig chunky but it can start to get a bit spendy for what it’ll be used for

swdanFree MemberPosted 8 years agoCheers Daftvader, that might be the way to go. If its good enough to make a sword on it’ll probably cope with whatever I throw at it!

nickjbFree MemberPosted 8 years ago2×4 all round will be fine. 3×2 is perfectly adequate if properly braced and a bit cheaper.

This sort if overlapping structure is much easier to build than the one in your link

swdanFree MemberPosted 8 years agoCheers nickjb. So I see you’ve used 2 lots of 2×4 for the legs and screw/bolted them together. I did consider this but thought it would be more faff. The link was for the basic idea, I was planning on cutting out a 2×4 section on the face of the 4×4 so that the bracing was flush. This was partly to make of look better and partly for some woodwork practice, however time, skills and tools may dictate a different design.

I like the way iurs looks, is that just studding?

nickjbFree MemberPosted 8 years agoNot my pic but I have a similar one. I think the doubling up of the 2×4 isn’t needed but you could do something similar but cut the outer one 100mm shorter and rebate the horizontal into it if you really wanted the flush look. You could get away with long screws instead of coach bolts too, just screw a few more in. Basically keep it simple, whatever you do will likely be strong enough and if it wobbles add another brace and a few more screws.

trail_ratFree MemberPosted 8 years agoI used 4×4 fence posts for legs – and studding for the top and bottom surface platforms.

proutsterFree MemberPosted 8 years agoI made this:

From this (3×3 fence posts for the legs, 2×3 for the bracing):

Using these instructions clicky

tonyplymFree MemberPosted 8 years agoIf you’re getting your timber from a merchant see if they have grade C24 rather than the more commonly found C16 – 50% extra bending strength (and usually fewer knots) for much less than 50% extra cost.

proutsterFree MemberPosted 8 years ago??? WOW, I (and my workbench and shed) feel inadequate now 😳

clodhopperFree MemberPosted 8 years agoMine uses 4×4 fence posts for the legs,with 4×2 stretchers morticed and tenoned into them, with the tenons then pinned with dowels. Top is 25mm MDF but kitchen worktop is ideal. I wouldn’t use a door as they tend to be thin ply over a light wood frame, which I’d not trust with heavy bench tools, or doing any serious work on. As for’ over engineering’; one of the most important aspects of a proper workbench, is solidity. You don’t want it wobbling about as that could even be dangerous. Strength is important if you are going to use a proper vice; you don’t want it shearing away and falling on your foot!

“This sort if overlapping structure is much easier to build than the one in your link”

It’ll be ok for occasional work, but any serious use will soon shake something like that apart. I’ve seen quite a few benches like that break. There’s a good reason proper woodworking benches are made in a particular way. My next bench will be made out of oak and/or beech.

I’d also avoid wheels unless you really need it to be movable, as they just make the whole thing wobbly, even with the castors locked. The type of wheels which are ‘retractable’ are the ones to use, so that the structure is sitting securely on the floor.

wwaswasFull MemberPosted 8 years agoI (and my workbench and shed) feel inadequate now

yeah maybe, but look at the state of that lawn through the windows.

finishthatFree MemberPosted 8 years agoRe treated fence posts – try to get ones that are very lightly treated and

as “aired” as possible – the treatments are not particularly nice and will stink out the area for ages if you are unlucky – aside from the health risk.

I would laminate thinner stock if there was none available – rather than use

treated fencing timber .

There are other “treated” timbers for construction – some of the treatments

are very strong smelling so its really worth getting untreated if you can.trail_ratFree MemberPosted 8 years ago“as “aired” as possible – the treatments are not particularly nice and will stink out the area for ages if you are unlucky – aside from the health risk.”

Dont chew your workbench would be my tip.

No stink at all here – although i did paint them straight after building.

one bench – where my pillar drill , bench grinder and air tools live.

MY “work bench”

qwertyFree MemberPosted 8 years agoI used reclaimed fenceposts for the legs & 4″x2″ elsewhere, with leftover joist supporting the vice.

[/url]IMAG1038 by martinddd, on Flickr[/img]

[/url]IMAG1167 by martinddd, on Flickr[/img]

Where’s Wally ❓

[/url]IMAG1188 by martinddd, on Flickr[/img]

I’d kinda like castors on the bottom of the posts to give 360′ access and moveability, but its fookin heavy empty, and then its loaded with tools.

fasthaggisFull MemberPosted 8 years ago^^Not mine,but I also made an area of my bench clear underneath so that I could sit at it like a desk.

Very handy when working with small stuff.nedrapierFull MemberPosted 8 years agoI made this one at the weekend. 4 notches, No fretsaw or jigsaw, just knocked out with a chisel and finished with a bastard file.

When we moved in, the internal garage was split utility/storage with stud wall.

Took out the stud wall, 2″ x 4″ timber was used for the frame, solid core door for the top. mdf for the shelf.

swdanFree MemberPosted 8 years agoCheers everyone, lots of stuff to digest when I get home from work and some garage envy going on.

Nedrapier, it was actually that that led me to original link, I thought laminating smaller pieces would be a pain but looks like it might be easier…

ourmaninthenorthFull MemberPosted 8 years agoMine is v similar to nickjb’s – built from 2×4. Build pics HERE.

Long since moved from the cellar to a garage. Now has whacking great vice I inherited from Mrs North’s grandfather. What you can’t see is some 2×4 diagonal bracing between the front and back legs on each side to limit twisting when “leaning” on seized items in the vice….

kcrFree MemberPosted 8 years agoJust refitted my garage with my old kitchen worktop and various bits of timber left over from building/garden work.

I used timber bolted into the walls to get a solid support on two sides, and built a horizintal frame from this, supported on the front edge with big post legs. Screwed it all together and screwed the legs to the floor with angle brackets.woodlikesbeerFree MemberPosted 8 years agoIf you want to do it properly….

[video]https://www.youtube.com/watch?v=ru2ZiNs_Wek&list=PLD39949332C7FB168[/video]

swdanFree MemberPosted 8 years agoThanks everyone, will take a trip to the diy shop at the weekend and see what I can find.I’ll report back how the build goes bit don’t hold your breath, may not be for a while… (I’ve have old pallets ready to be turned into a wood store sitting under the car port for nearly 2 years!)

chestercopperpotFree MemberPosted 8 years agoSome gratuitous vice shots there mmmmmmmmmmmmm.

Who’s got the biggest?

TooTallFree MemberPosted 8 years agoI wanted a taller bench (go figure) and didn’t have the tools for woodworking back then…….

Piece of old laminate worktop, 2 x lengths of 3×2 glued underneath to prevent bowing, all of it sat on 2 of these:

Telescopic TrestlesClear space underneath, custom height, portable for when I moved house.

spooky_b329Full MemberPosted 8 years agoAfter ripping out my old woodworm infested bench (proper old skool woodworking thing) I am in need of a new one.

Any particular disadvantages in making one fixed to the wall i.e. longitudinal timbers at the rear and just legs at the front?

thebeesFree MemberPosted 8 years agoMy bench is made from a 2 by 2 bolted to the wall, with a kitchen worktop sitting on top. The front has three legs of 3 by 3 prepared timber fixed to a length of 2by 2 which is screwed to the underside of the bench. Plus some bracing for the legs.

It’s been used for several years and is solid as a rock. Bolting to the wall is the best starting point for any bench. My bench has been used to hold steel tube whilst being heated and bent with a scaffold pole extension so it has probably faced the worst kind of abuse / testing !

My one tip would be to make sure that the holes you drill in the bench are exactly the same size as the holes in the vice and that you buy bolts that have a tight fit. You don’t want any freeplay here at all, as it only gets worse with age.

Cheers.

The topic ‘What wood for a workbench frame?’ is closed to new replies.

[/url]

[/url] [/url]

[/url] [/url]

[/url]