- This topic has 33 replies, 19 voices, and was last updated 9 years ago by thestabiliser.

-

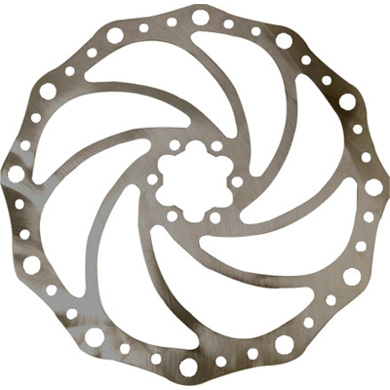

Rotors on wrong way round – will I die?

-

geoffjFull MemberPosted 9 years ago

I know its not rocket science to put them on the right way around, but in my defence I was trying to match them for a Cotic fork with the brake mount the other way.

They look like this –

The bolts they came with have heads made of cheese, so I’m not desperate to re-fit them until I can get some decent bolts.

Whaddya think?

wwaswasFull MemberPosted 9 years agoIt’s a really, really bad thing to run them the wrong way round.

scotroutesFull MemberPosted 9 years agoChange them round. The “spoke” pattern is engineered like that for a reason.

cynic-alFree MemberPosted 9 years agoNever really understood why – surely it’s as strong with the spokes in compression as in tension?

blahblahblahFree MemberPosted 9 years agoI’ll just leave this here Thread

But you should probably heed the comments above!

andylFree MemberPosted 9 years agosurely it’s as strong with the spokes in compression as in tension?

nope, they are flat sheet with low stiffness so can buckle easily.

OP – yes you will die, eventually

as a result of your brakes being the wrong way round – who knows?

I’d not do any aggressive braking with them that way as it would be annoying to trash new rotors.

nickjbFree MemberPosted 9 years agosurely it’s as strong with the spokes in compression as in tension?

try hanging from a thin bit of metal then try standing on it. Should show you if it is as strong in compression as tension.

edward2000Free MemberPosted 9 years agoNever really understood why – surely it’s as strong with the spokes in compression as in tension

Materials testing engineer to the Forum! I hear you shout…

Hello!!

No. Not as strong in Tension as in compression. Also there are many different definitions of strength. Fatigue resistance is important here. The rotor may indeed be trying to collapse in on itself if the rotational force goes one way and not the other. It’s fatigue strength will be weakened if the rotor is used the wrong way around.

I’d turn those around pretty quick.

cynic-alFree MemberPosted 9 years agoNot entirely clear why they buckle more easily under tension (if they do).

I’d ask for an explanation but my experience is people who claim they are right can’t explain and just gang up on me saying it’s obvious!

nickjb – Member

surely it’s as strong with the spokes in compression as in tension?

try hanging from a thin bit of metal then try standing on it. Should show you if it is as strong in compression as tension.

Of course. You realise you are actually backing up my point?

andylFree MemberPosted 9 years agoNot entirely clear why they buckle more easily under tension (if they do).

I’d ask for an explanation but my experience is people who claim they are right can’t explain and just gang up on me saying it’s obvious!

Well I could explain it and I dare say I would hope I would do so clearly and have never told anyone “it’s obvious” but that seems a bit insulting 😕

blahblahblahFree MemberPosted 9 years agoAl,

I’ll try and explain for fun…

It doesn’t have as much to do with tension and compression as you’d think. With a disc one side is always in compression, the other in tension, under braking.

Look at the first (correct) and second (incorrect) photos in this thread. Now imagine the disk caliper at the 3 o’clock position. The side of the disc above the caliper is in tension, below in compression.

Now look at the orientation of the spokes of the disc.

In the first picture the spokes on the tension side of the disc are pretty much vertical and taking all the force down their length. (Nice and strong and stable from a buckling perspective)

In the second picture they are almost horizontal. The tension force is acting across the spoke is incorrectly oriented to stop the top of the disc collapsing and buckling.

That’s why there is a difference in orientation.

Perhaps someone could elaborate on my explanation if it is unclear.

nickjbFree MemberPosted 9 years agoNot entirely clear why they buckle more easily under tension (if they do).

They don’t. That’s why they are mounted so the spokes are in tension.

Of course. You realise you are actually backing up my point?

No I’m not.

It seems you are under the impression the correct way round puts them in compression. I think that may be the issue.

isitaboutabicycleFree MemberPosted 9 years agoThat was pretty good, I reckon! The first thing that will buckle – ‘taco’ – is the braking surface, not the spokes. Assume pin-joints at the ends of the spokes and then in the proper direction they will tend to spread outwards, putting the surface in tension. The other way and the surface will go into compression and buckle, even though the spokes are in tension.

Hopefully that’s not a load of rubbish, I’m only a first year.

You can approximate as pin-joints fairly well as the ends of the spokes will take small moments relative to the other loads around, I think.andylFree MemberPosted 9 years agoOkay, I’ll try a different take as it’s a hard one to get your head around.

Remove the outer ring/braking surface and imagine the spokes are flexible like brush bristles.

If the rotor/brush is spinning and you put you move something into the bristles and they are the wrong way then they will offer little stiffness and fold inwards to the hub. Now spin it the other way and the bristles will want to straighten up.

It is to do with the tangential vs axial loading of the bristles/spokes. If you use a long ladder quite horizontal then you bounce around a lot more than using a shorter ladder more vertical as you are applying the load in a direction where the beam is less stiff. (example comes to mind due to recent observation of someone on a ladder!)

Now if you get a sheet of A4 paper and hold one short end in one hand and swing it back and forwards in an arc edge on to simulate the braking surface. Then pinch near to the other short end with your finger and thumb on the other hand the paper will wrinkle and buckle and in doing so pull your hands towards each other.

The spokes are there to prevent that happening and provide stiffness to the braking area. Going back to the bristles they are less able to do that when they are more inclined to fold inwards towards the hub.

Photos of ashima rotor here:

You can make out the spoke folding under load from the brake.

it’s a ‘bit’ like pawls in a freehub – one way they collapse and allow free rotation, the other they bite and allow drive.

andylFree MemberPosted 9 years agonickjb – Member

Not entirely clear why they buckle more easily under tension (if they do).

They don’t. That’s why they are mounted so the spokes are in tension.

Of course. You realise you are actually backing up my point?

No I’m not.

It seems you are under the impression the correct way round puts them in compression. I think that may be the issue.Actually, there are parts in compression and buckling which is why I didn’t reply as you did there.

You are talking purely about the spokes. There are buckling loads on the disc itself on the side approaching the pad. the side leaving the pad will be in tension.

The spokes are trying to stabilise the braking surface and counteract the forces it is experiencing.

andylFree MemberPosted 9 years agojust to correct myself a bit – spokes are there to transfer the braking torque into the wheel hub and stabilise the braking surface (or you would be in trouble and this is where they fail and then allow the outer braking surface to fail) and if you do the sheet of paper thing holding the paper firmly at a point it will demonstrate the forces on the rotor quite well and you will see the paper distorts most close to your hand that is rotating it – ie close to the rotor hub as that is where the torque is higher due to mechanical advantage. This is

Also the curve on the spokes is just design from what I can see (in my head) and the key factor is the tangential angle at which the spoke leaves the hub area. I think shimano are good to demonstrate this as they often use straight spokes canted at an angle from the hub instead of fancy curved spokes.

blahblahblahFree MemberPosted 9 years agoThat photo of the bent Ashima disk illustrates it well. You can see where a spoke, in the horizontal orientation, has been unable to support the bending moment imparted by the rotor surface.

It has buckled and allowed the rotor surface to collapse.

cynic-alFree MemberPosted 9 years agoI’ll read this when sober, but I do not get this at all, seems the wrong way round:

It seems you are under the impression the correct way round puts them in compression. I think that may be the issue.

slowoldgitFree MemberPosted 9 years agoI’d rather have my disc spokes in tension, because I believe it avoids ‘chatter’* and therefore shrieking brakes. YMMV.

*That’s what it’s called in woodwork. Is it the same with metals?

nickjbFree MemberPosted 9 years agobut I do not get this at all, seems the wrong way round

The simple way to work it out is the same for pedal threads and bottom brackets. Work out which way you think it should be and it is the opposite way 😀 I believe those buckled Ashima rotors were labelled to be fitted the other way to conventional wisdom as they came to the same (incorrect) conclusion.

shermer75Free MemberPosted 9 years agoThis is good. A ‘will I die’ thread where there is a slim possibility that you might actually die. Finally!!

unovoloFree MemberPosted 9 years agoOr fit some Hope floating rotors and it shouldnt* matter which way you fit them as they dont have the angled legs like stamped rotors.

*not a expert so fit at your own risk.thestabiliserFree MemberPosted 9 years agoI’ve got those ashima rotors, not sure if they’re stamped right or not. Rsndom Factor like a tractor!

bencooperFree MemberPosted 9 years agoFirst picture on this thread is correct. The spokes of the rotor should always point forwards. Most rotors have markings on them anyway.

AlexSimonFull MemberPosted 9 years agoConfused.

Just checked my Ashimas and they are printed what I feel to be the correct way around.

But surely the OPs original picture is the correct way around too?i.e. When the brakes are trying to prevent the wheel from rolling, the spokes will be in compression?

Mine are like the the OPs original image, and opposite to the pics of broken ashimas up there and also opposite to Ashima’s ‘forces’ diagram on the other thread.

Edit: While I was off checking, Ben beat me to it!

steve_b77Free MemberPosted 9 years agoI’d not do any aggressive braking with them that way as it would be annoying to trash new rotors.

What on earth is that? Not shouting at squirrels and badgers??

slowoldgitFree MemberPosted 9 years agoI think the reason for inclined spokes is to give a bigger tolerance of expansion and contraction. Hence the simpler design of the floating rotor above.

Yonks ago someone on here wrote that there were patent issues with inclined spokes.

SundayjumperFull MemberPosted 9 years agoIt’s not so much about tension/compression of the spokes, more about tension in the braking surface. With the spokes pointing forward, then under braking they are trying to push outwards which keeps the braking surface tensioned and stable. With the disc the wrong way round they try to pull it inwards and you risk collapsing the disc as per the Ashima pic.

29erKeithFree MemberPosted 9 years agoI had some ashimas with the arrow miss printed and didn’t notice at the time, they stayed like that for a year or more until a mate pointed it out and I swapped them. I didn’t die but was lucky tbh

thestabiliserFree MemberPosted 9 years agoThe Ashimas in the pic above look like they were on ‘pointing forwards’ surely the big kink is them wrapping around the caliper? Am I ‘mis-seeing’ this?

bencooperFree MemberPosted 9 years agoIt’s perhaps easier to imagine the disc isn’t round, it’s a linear thing – so you’ve got two opposing forces, with angled struts between them. Using ASCII art:

Correct:

Braking force ->

\\\\\\\\\\\\\\\\

<- Rotation forceLooking at it that way, you can see how the struts are in compression.

Incorrect:

Braking force ->

////////////////

<- Rotation forceLooking at it that way, you can see how the struts are going to fold over. that’s what happens with the disc, except instead of folding over, they wrap around the hub.

thestabiliserFree MemberPosted 9 years agoAppreciate that but on the above it looks like the caliper was at 3 o’clock with the rotor turning clockwise (i.e. the bit ‘in the caliper’ remained realtively straight with the bit rearward of [- coming in to] the caliper bent toward the spokes of the wheel?

I’ll look at the original thread.

The topic ‘Rotors on wrong way round – will I die?’ is closed to new replies.