- This topic has 24 replies, 17 voices, and was last updated 6 years ago by Sandwich.

-

DIY Plumbing reassurance please

-

B.A.NanaFree MemberPosted 6 years ago

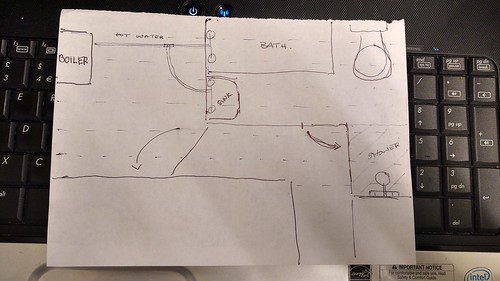

New shower going in, all tiles, tray and boarding is about to be ripped out by me ready for the tiler to start. Old shower was electric (so cold supply already there), but I want to go mixer (thermostatic exposed bar), so require hot water feed from my combi boiler (new Ideal Vogue 32).

Boiler is about 10 ft away on same floor, joists are running in my favour. The carpet in the small room with the boiler can come up dead easy, so it all seems a no-brainer to go mixer and looks like a dead easy job to pipe to the shower area.

So, in the sketch attached (dotted lines are the joists), 1)is it simply a case of taking a tee off the hot water pipe running to the bath/sink taps?. 2)Is there any particular best practice point on the pipe to take a tee for the shower? 3) are all brands of 15mm flexi plastic pipe/fittings ok to mix ie a grey none brand pipe with me using a JG speedfit tee to splice in?. Anything else I need to consider?.

dannybgoodeFull MemberPosted 6 years agoThere are two jobs I am happy to pay someone for. Plumbing and electrics!

wobbliscottFree MemberPosted 6 years agoTee-ing off the bath hot water supply is fine. Might be easier to route up into the loft space if there is a loft to save routing through walls and under floors and between joists – generally better to avoid as many bends in the routing as possible so if you go into the loft you can go direct point to point. Can’t advise on plastic fittings, never used them.

somoukFree MemberPosted 6 years agoWith regards to taking a tee off the taps, that’s fine if everything is running correctly and the pressure is high enough to support the shower. I’ve just gone from electric to mains for the shower and the plumber took the feed off the bath taps but the bath had 22mm pipes running to it so plenty of spare flow for the water for the shower.

If i was you I would be inclined to de-commission your old cold water feed completely and take a common tee from the cold tap next to the hot. This keeps it cleaner from an installation and fault finding perspective.

Remember to budget in isolation valves for the shower feeds and caps for the pipes that come out the wall so you can pressurise it and test joints before it gets tiled over.

I am in the same boat as dannybgoode, I pay people for spark and water.

wrightysonFree MemberPosted 6 years agoDon’t forget the inserts in plastic pipe. “Lock off” the fittings, they have about a quarter to half turn I believe once installed. Fit an inline baller fix valve or similar to both the hot and cold feeds somewhere that is easily accessible (not under a tiled floor etc) as some mixer bars have limited life spans. Use as little elbows as possible so as not to restrict flow. Have towels handy…

philjuniorFree MemberPosted 6 years agoThe only thing to bear in mind is allow some space for expansion/contraction, esp on plastic pipe. And make sure all fittings are engaged properly.

wobbliscottFree MemberPosted 6 years agoWater is actually quite easy. The biggest problem is routing and gaining access, but fittings are generally fool proof. I’ve installed showers, toilets, sinks many times and fixed some issues left by the pro’s – just because they’re pro’s doesn’t mean they always do a good job. I’ve never had any issues with stuff I’ve done myself, just stuff pro’s have done. Just take your time, do your research and be methodical about it.

Good advice on isolation valves – great for future jobs or replacement of fittings without having to faff around with the rest of the system.

sig123Free MemberPosted 6 years agoAs above for piping but NEVER mix and match your fittings and pipe because they are all slightly different.

neilnevillFree MemberPosted 6 years agoAnything else? – don’t forget to secure the pipes so they don’t knock when taps are opened, especially important with plastic and mains pressure.

RustyNissanPrairieFull MemberPosted 6 years agoTake the opputunity to remove as much original copper as possible and replace with plastic. On our previous house i piped everything (radiators, hot and cold feeds, all taps) in 15mm JG plastic – this allowed hot water to come out of the taps/shower quicker than having copper absorb the heat before it eventually flowed out of the tap/shower consistantly.

It was noticeable at my PIL house that had a combi boiler and long runs of original copper pipe.squirrelkingFree MemberPosted 6 years agoWhatever manufacturer you use go to their website and follow their instructions.

I went with JG Speedfit, not a problem (touch wood) since it was all installed 3.5 years ago.

As RNP says plastic is less conductive. As also said take off a 22mm line as opposed to 15mm. Some idiot plumbed the house entirely in 15mm and you notice the pressure/flow drop (albeit slight) if other things are demanding water 😳

B.A.NanaFree MemberPosted 6 years agoThanks, I can’t do much about the existing pipes which are 15mm from the boiler, water pressure is very good and house is small so doesn’t appear to have been an issue.

It looks like it may be possible to run a continuous pipe to the shower outlet point from a tee into the existing hot water pipe just beyond the boiler (to bath and sink).As above for piping but NEVER mix and match your fittings and pipe because they are all slightly different.

This is my only concern now, I have no idea what the existing hot water pipe is (brand or where from), it’s just grey and looks non branded. If I cut into it with such as a jg speedfit tee fitting, what’s the likelyhood bad things going to happen?

Blazin-saddlesFree MemberPosted 6 years agoIf it’s Grey it’s most likely Hep2o. The external diameters are all the same for all systems, it’s the internal that changes ever so slightly, you might need to try a metal insert rather than the JG super seal version.

DT78Free MemberPosted 6 years agoNEVER mix and match your fittings and pipe

my house is full of mix and match….

If I was to pick a plastic system to replace things with, what is recommended. I *think* we have some speedfit stuff. Supposedly you remove and refit copper piping, no chance I could when I had to replace a broken tap on boxing day. It has a collar that I believe you push in, but I couldnt.

As for paying for water and electric, I would if I had the money and the patience to wait. As above most of the challenge is access not actually putting the stuff together.

GavinTFree MemberPosted 6 years agoSpeedfit works very well indeed on std copper pipe. Just make sure it’s cut cleanly and all burs removed. If it’s old or painted then give the area going into the fitting a good clean up with emery cloth / wire wool. The long strips of emery cloth on a roll are great for this.

I’ve done this in several places with no problems at all.RockhopperFree MemberPosted 6 years agoDon’t ever stick your finger into a Speedfit connector to see how it works.

neilnevillFree MemberPosted 6 years agoOne other thing to watch, plastic means breaks in the electrical conductors, so you’ll need to add earth bonding.

B.A.NanaFree MemberPosted 6 years agoshined torch well under floorboards think I can just about see polyplumb printed on the pipe, Looks like B&Q sell it and in short lengths / one offs, so won’t have to buy a massive reel of pipe or multi bags of fittings, when I only need 6m of pipe and ones ‘n’ twos of fittings. Happy Days, cheers

B.A.NanaFree MemberPosted 6 years agoAnyone know if Polyplumb (B&Q) is same as Polypipe (Plumbcentre)?

DT78Free MemberPosted 6 years agoOne other thing to watch, plastic means breaks in the electrical conductors, so you’ll need to add earth bonding

Do you *really* need to do this if the majority of your plumbing is plastic up to the outlet – I have a mix of lead, copper and plastic, I’m bonded at the stopvalve but not at the actual taps, most of the taps you can see are linked to a plastic speedfit fitting, so the chances of the bit behind the sink / bath coming into contact with a live wire (there are none in the vicinity) is zero.

I thought the risk was a wire somehow coming into contact with a pipe and making it live. Surely the plastic insulates that from happening (unless you are running a follow stretch of copper from the plastic?)

Anyone have any tips for removing copper from a speedfit fitting?

neilnevillFree MemberPosted 6 years agoI’d agree with your logic but I’m not sure what the building regs say on earth bonding, its in there somewhere i think.

nealgloverFree MemberPosted 6 years agoNEVER mix and match your fittings and pipe because they are all slightly different.

Outside diameters are all the same regardless of brand. Which is why you can mix and match fittings and pipe no problem.

You just need to make sure you use the correct inserts for the pipe.Mixing and matching is totally fine.

squirrelkingFree MemberPosted 6 years agoSupplementary bonding is no longer required provided you have RCD’s fitted on all circuits. This has been the case since 17th Edition came into force.

stumpyjonFull MemberPosted 6 years agoI really don’t think matching the brands is an issue. Use the pipe inserts and make sure everything is connected correctly, brands do work in different ways, some need locking, others just push in but make sure the pipe is pushed in all the way. A set of pipe cutters is also useful for clean cutting.

My whole house, both heating and water is plastic put in when it was built 15 years ago. I’ve modified and extended quite a bit. Only issues have been me not fully inserting pipes into fittings correctly. Plastic is much more forgiving and quicker than copper.

SandwichFull MemberPosted 6 years agoDon’t ever stick your finger into a Speedfit connector to see how it works.

Is there something you’d like to share? 😆

The topic ‘DIY Plumbing reassurance please’ is closed to new replies.