- This topic has 18 replies, 8 voices, and was last updated 8 years ago by alexxx.

-

Help me with gear ratios…

-

alexxxFree MemberPosted 8 years ago

I just need a sanity check as I’m hopeless with these kind of calculations.

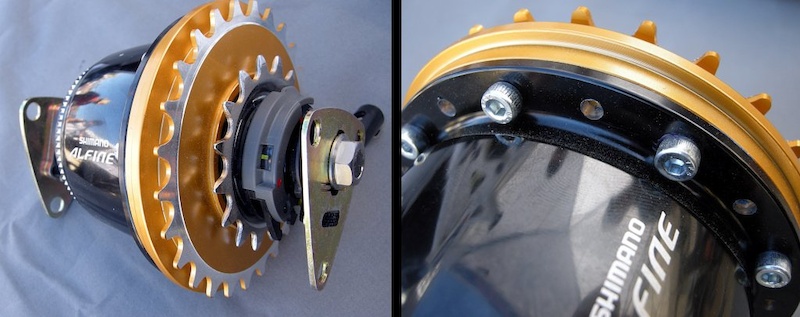

I’m trying to work out if I can make my zerode a singlespeed for a fun small project and do away with the alfine hub.

At the moment here are the current cog sizes:

32 tooth on the cranks

16t on the alfine as the input (chain connects to the 32tooth cog on cranks)

26t on the alfine as the output (chain connects to the 21tooth backwheel cog)

21tooth on the rear wheelI’m stuck with a 32t on the front as there are clearance issues… I maybe able to slip down a little but certainly not up any sizes.

Any thoughts welcome. I’m thinking I’ll probably use a bmx freehub to replace the alfine or similar and weld on the other cog or set it on a spline.

Since I’m choosing a single gear I’m looking to calculate the equivalent of a 3:1 type ratio?

Thanks / Sorry / Scatty!

billyboyFree MemberPosted 8 years agoHave a look at the Sheldon Browne website.

Off the top of my head……….. I don’t do single speeds, but I think you probably need something like a 60 inch gear for the bike to cope with most stuff on the road. Off road you might want lower. If my memory is correct, you work out gear inches by the number of teeth on your chain ring (32 in your case) times the tyre size of your bike ( you don’t say, but 29″, 26″ etc) divided by the teeth on the rear sprocket. If you do a bit of research and find out what the consensus is for for the best gear inch for your purpose, then you will have two parts of the calculation and the answer, so you should be able to get the one missing bit of the calculation from that.

alexxxFree MemberPosted 8 years agoHey yep – it’s purely for a downhill gear (its a 9” dh bike) so I was looking for a gear thats an equivalent to say a 36 on the front and 7th gear on the back (12/13tooth?).

I guess my head is getting a little boggled as its going to the axle above the cranks first as this bike runs a 2 chain system. So its how to pop that into the equation correctly.

davidtaylforthFree MemberPosted 8 years agowhat’d happen if you got a chain tensioner and just ran the chain straight to the rear hub?

davidtaylforthFree MemberPosted 8 years ago7th on the back is a 14tooth I think. 13 with the 32 should do it. Just keep those two rings where the alfine is the same size as each other, and bobs your uncle.

chiefgrooveguruFull MemberPosted 8 years agoDT it’s a high single pivot which would have a huge amount of chain growth with a single chain, causing horrible kickback and excessive anti-squat – and a chain tensioner would need to be the size of a medium cage mech to cope.

davidtaylforthFree MemberPosted 8 years agoTo be fair Alex, it looks like a right palaver

Get yourself back on SDH and see if you can find someone willing to sell you one of the North East’s finest; a Mr Big Racing frame. I think they can be run SS from what I remember.

bigblackshedFull MemberPosted 8 years agoAs I understand it you have two rings on the Alfine, one connected to the crank, one connected to the rear wheel?

First I’d use a normal rear hub with a 9/10 speed free hub body in place of the Alfine in the frame. You’ll have lots more options to get the chain lines correct. Don’t weld the sprocket on, how will you remove it when it wears?

What gear ratio are you selecting in the Alfine? Is it an 8 or 11 speed?

Apart from losing the weight of the Alfine what are you trying to achieve? Or is this to see if you can do it?

cookeaaFull MemberPosted 8 years agoThe gearing will probably be based around the alfines 1:1 gear (about mid range right)

So (32/16=2)x(26/21=1.23)=2.47

Near as damn it a 2.5:1 ratio… Quite close to 32:13

For simplicity sake I would keep the 32-16 primary gear and maybe look at ways to vary the second stage ratio… Maybe start at 20-16 and go from there…

I am guessing the 26t at the alfines is a special, drilled/ adapted so it can be bolted to the drive side spoke flange on the alfine?

If you’re looking to replace the alfine with some sort of SS hub maybe look for something in 36h with a larger flange to make machining a sprocket to suit a bit easier…

Or put a disc hub in there backwards (disc mount on the drive side, may need some re-spacing of the axle too?) and try spacing a couple of these disc mounting sprockets… on there, making sure you have a working freewheel on the rear hub..

cookeaaFull MemberPosted 8 years agoIn fact thinking about it OP, you don’t actually need a “hub” you need a double sprocket mount with a couple of bearings, ideally something you can adjust the centres on… Know anyone with a lathe and mill?

cookeaaFull MemberPosted 8 years agoBingo:

I guessed right for once…

And from a brief googling it seems like the Zerode uses a regular freewheeling rear hub normally, does the alfines freewheel do much normally?

cookeaaFull MemberPosted 8 years agoIn fact, there’s an even simpler way to do it, albeit without the weight saving…

Google tells me that gear 5 on a SG-S500 (alfine 8) is the 1:1 ratio. So select gear 5, Mark the actuating arm at the hub so you can find the position again, then disconect the shifter and cable and use a short stub of gear cable mounted between the arm and the cable adjuster to line up that position again… You now have a single speed 2.47:1 ratio Zerode…

billyboyFree MemberPosted 8 years agoSorry…didn’t realise what the bike was.

Way too complicated for me

alexxxFree MemberPosted 8 years agoHey all sorry – just seen all these replies – I thought my question had died 🙂

It is a “can I do it” project but also a weight saving one for curiosities sake.

The rear does have a normal hub but it doesnt need it. I guess its just common place to find a normal 150mm 9 speed hub.

I’m going to go down the road of butchering of a hub I think as I don’t have access to a friend with a lathe sadly.

What dave suggested later about the rings sounds right too? Simply keeping the teeth at the alfine part the same size so it’s easier to calculate ratios? Did I understand that right dave?

Also its a 8 speed alfine.

SuperficialFree MemberPosted 8 years agoYeah that seems reasonable to me. And you could presumably use any old 135mm spacing hub instead of the Alfine.

There’s a freehub in the rear wheel, right? In which case you don’t even need a hub, just an axle with two sprockets on, although it’s going to be a lot easier to just find a hub. As far as I can see, I don’t think you would need one sprocket on the freehub and one attached to the hub shell. If you don’t need it to shift, you can just mount both to the cassette carrier.

It seems like a lot of fuss for zero gains. Or perhaps, Zerode gains. Ha.

alexxxFree MemberPosted 8 years agoI love a good pun 😀 – I know there isn’t much point but I fancy a fettle! I’ll see what I have lying around

Thanks for the clarity guys

The topic ‘Help me with gear ratios…’ is closed to new replies.