- This topic has 57 replies, 38 voices, and was last updated 11 years ago by Singlespeed_Shep.

-

Frame failures – At which low temperature do you not risk riding your mtb?

-

martinxyzFree MemberPosted 11 years ago

Me, I’ll go with -30c.

Although if it drops to -30c and its still cloudy I might, MIGHT risk -32c.

😛

martinxyzFree MemberPosted 11 years agoThe mud is the scary bit. It could hide cracks similar to a windscreen shattering. Not worth it.

This is the type of mud transported around in a jar on rides, I take it? The stuff you slap on to make the bike look the part? :O)

munrobikerFree MemberPosted 11 years agoWhere’s TJ? I’m sure he has studied the possibility of this ACTUALLY happening in minute detail from websites (rather than real scientific sources) and can give you a genuinely misinformed answer about this.

dukeduvetFull MemberPosted 11 years agoMore bothered about my xt brake seals leaking in the cold and the resultant crash or fluid over pads and disks

NorthwindFull MemberPosted 11 years agoIt’s not a consideration tbh, UK doesn’t get that cold- cold enough to be not much fun to ride in mind.

tomhowardFull MemberPosted 11 years agoAt the temps that would have me worrying about the bike, I’d have bigger worries. Like how to deal with the upcoming ice age.

andylFree MemberPosted 11 years agoWell the temperature commercial aircraft fly at is at best about -30degC and they are made out of aluminium and composites and they don’t have any problem.

I’d be more worried about seals and lubricants and my own body.

GreybeardFree MemberPosted 11 years agocommercial aircraft fly at is at best about -30degC and they are made out of aluminium

When I flew to Japan, crossing over Siberia at 2am, the info screen showed -72ºC outside. But aluminium is actually aluminium alloy, and a lot depends on the mix and the heat treatment. The thing that impressed me most was the ability of the engines to work in those temperatures.

maccruiskeenFull MemberPosted 11 years agoSeaside Winkie Dancake

Quite fancy a shanty. You hum it I’ll join in at the chorus.

martinxyzFree MemberPosted 11 years agoSorry, I was taking the mickey. I just read on another thread about folk worrying about riding in the cold with carbon.. not just alloy!

toys19Free MemberPosted 11 years agoThe phenomena is called the Ductile to Brittle Transition and Steel with BCC unit cells is the material that suffers this. Which menas pretty much all steels bikes are made of unless they are FCC stainless (like 306/316 etc).

In fact some aluminium alloys actually get more ductile at low temps. (6061 T6 for example) I can explain that if anyone wants to know about slip planes and arrhenius equations.

Back to steel though – most modern steels have been fiddled with to depress the ductile to brittle transition temperature (DBTT) so in Uk conditions there is not much of a worry. This was mostly as a result of the liberty ship failures.

Although I would not be completely convinced that all manufacturers of bikes/components even know anything about metallurgy and have any awareness of the DBTT and may well have specced a rare steel which still has a relatively high DBTT for some other reason (like cost, or having it foisted uppon them by a salesman/manufacturer).

Relatively high means -5 or even zero..

goodgriefFree MemberPosted 11 years agoI went through a phase of worry for my sdg seatpost after hearing of a few cold-related failures but it doesn’t bother me so much now.

because I don’t use it anymore.rockymerlinFree MemberPosted 11 years agoInteresting.

Where can I find out about ductile to brittle transition temeratures and also BCC and FCC steels please?

toys19Free MemberPosted 11 years agowell pretty much the only fcc steels are stainless.

bcc are all carbon steels apart from some of the mega high strength ones which are BCT, I can’t remember if the BCT ones are any good at low temps or not, semi pissed now…

It is hard to find a modern carbon steel that has not had its DBTT depressed significantly.

The best book on steels is Steels, Metallurgy and Applications by DT Llewellyn.

Or look in the ASTM series, I have lots of stuff on PDF/ereader that might be helpful.

Other than that here is a quick google.

https://www.google.co.uk/search?q=ductile+to+brittle+transition&ie=utf-8&oe=utf-8&aq=t&rls=org.mozilla:en-GB:official&client=firefox-a

http://www.exo.net/~jillj/activities/mechanical.pdf

http://en.wikipedia.org/wiki/Ductility#Ductile.E2.80.93brittle_transition_temperature

http://materialiaindica.ning.com/forum/topics/ductile-brittle-transition

https://www.google.co.uk/search?q=liberty+ships+failures&ie=utf-8&oe=utf-8&aq=t&rls=org.mozilla:en-GB:official&client=firefox-a

http://en.wikipedia.org/wiki/Liberty_ship#Problems

http://en.wikipedia.org/wiki/Ductile-brittle_transition_temperature#Ductile-brittle_transition_temperature

https://www.google.co.uk/search?q=materials+for+cryogenics&ie=utf-8&oe=utf-8&aq=t&rls=org.mozilla:en-GB:official&client=firefox-a

http://www.journalamme.org/papers_amme03/1240.pdf

http://www.google.co.uk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=8&cad=rja&ved=0CHoQFjAH&url=http%3A%2F%2Fwww.springer.com%2Fcda%2Fcontent%2Fdocument%2Fcda_downloaddocument%2F9781441999788-c1.pdf%3FSGWID%3D0-0-45-1326037-p174117366&ei=SPr6UJuKDMil0AXI5YDwDA&usg=AFQjCNGMQIYKUe0dFWRW4PeKa9Be7xbzZw&bvm=bv.41248874,d.d2k

http://www.slac.stanford.edu/cgi-wrap/getdoc/slac-tn-03-023.pdf

http://cryogenics.nist.gov/MPropsMAY/5083%20Aluminum/5083Aluminum_rev.htm

http://cryogenics.nist.gov/Papers/Cryo_Materials.pdfA good explanation of Unit cells (which is what FCC and BCC refers to) is here and on wikipedia here.

stucolFree MemberPosted 11 years agoIf your frame is going to crack with the cold then i think your forks may sieze up first.

Or your bars snap, or your bearings/freehub/BB/headset etc etc etc.

Freehubs tend to go first i find.

iaincFull MemberPosted 11 years agoColdest I have ridden is about -12, on a mugdock nite ride. Mechs and brakes stop working, then toes and fingers, a long way before frames and other fixed metal bits

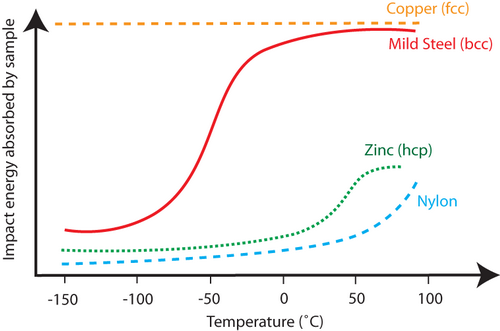

toys19Free MemberPosted 11 years agoFYI this graph is an excellent indicator of the difference in low temperature mechanical behaviour of FCC and BCC metals.

wobbliscottFree MemberPosted 11 years agoThe International Space Station gets pretty cold ( less than -100 degs C) and that is made of Aluminium Alloy and Titanium, so I think we’re fine. The al alloys that decent bike frames are made from are very similar to that used on aircraft, which again get pretty cold, certainly colder than you’d consider riding in.

NorthwindFull MemberPosted 11 years agowobbliscott – Member

The International Space Station gets pretty cold ( less than -100 degs C) and that is made of Aluminium Alloy and Titanium, so I think we’re fine.

Yeah, but how well would you get on riding it round a lap of laggan black?

T1000Free MemberPosted 11 years agoBorrowed a workmates spare town bike and biked to the office in Helsinki at -25 saw some other folks riding around on similar bikes … Totally unremarkable there….

mick_rFull MemberPosted 11 years agoI remember Liberty ships and brittle fracture of welded steel structures from metallurgy lectures.

Wonder what happens with my home made steel frames joined with brass – which is an alloy of copper (from the graph above really good at low temps) and zinc (really bad when cold) ?……

DougDFull MemberPosted 11 years agoNorthwind – Member

wobbliscott – Member

The International Space Station gets pretty cold ( less than -100 degs C) and that is made of Aluminium Alloy and Titanium, so I think we’re fine.

Yeah, but how well would you get on riding it round a lap of laggan black?

It’d be out of this world.

igmc

enfhtFree MemberPosted 11 years agoI know a robot who thinks the relative difference in UK seasonal temperatures is nothing compared to glowing orange.

toys19Free MemberPosted 11 years agoI think brass goes to BCC of the Zinc – it defo does with beta brass which is CuZn (Ie 50/50) . So it will be crap at low temps, but I cannot remember what brazing brass is. Brass varies from FCC to Bcc depending on composition…

fizzicistFree MemberPosted 11 years agoRidden at -17C on my Soul.

No change in the feel of things other than the fork was a lot firmer than normal as the oil had become more viscous.

somafunkFull MemberPosted 11 years agoIf my non-riding in the past few months is any thing to go by it appears i don’t ride in anything under 10 degrees C, i prefer to ride in temps between 18 – 22 degrees C. Unfortunately this has not happened very much this past year.

hamishthecatFree MemberPosted 11 years agoI broke a USE seatpost clamp in -10 temperatures. Not saying much though. 😕

RoterSternFree MemberPosted 11 years agoI’ve ridden my On One SS in -25 degs without a problem so I would say if you are based in the UK you have nothing to worry about. 😉

coolhandlukeFree MemberPosted 11 years agoIf it gets as low as -273, I’d probably not bother to go mountain biking.

singlespeedstuFull MemberPosted 11 years agoI am more worried about mr Winkie turning into a foo-foo

I tie a bit of string to mine before I go out in the cold.

That way if it does turn inwards I can yank it back out again with the string.

saleemFree MemberPosted 11 years agoMartin you’ve always got another 6-7 if one goes pop or just hold it together with a few fishing rods and duck tape.

jamesFree MemberPosted 11 years agoI’d be more worried about an SDG Ibeam seatpost

Seem to remember a few threads a while back about those breaking in the coldmartinxyzFree MemberPosted 11 years agoI have 2 sdg I beams on the mountain bikes and have ridden 2 winters ago in -10c with 13.5stone on them. Both are holding up fine. Worth it for the comfort of those fx saddles. Mmm.

coffeekingFree MemberPosted 11 years agoThe International Space Station gets pretty cold ( less than -100 degs C) and that is made of Aluminium Alloy and Titanium, so I think we’re fine. The al alloys that decent bike frames are made from are very similar to that used on aircraft, which again get pretty cold, certainly colder than you’d consider riding in.

Orbital loading of the ISS is tiny, not even a remotely comparable application! Add to that the fact that alloys massively change properties with heat treatments and are very customisable, that’s a generalisation you really can’t make, unless you were a mechanical engineer working on a chunk of the ISS?

That said, I’ve never found myself considering my frame strength in the cold, even when I had a carbon full sus. I know that most decent composite resins will cope happily down to -40 and the fibres themselves will too. I have never considered the DBTT of steel for reasons of assuming most manufacturers would have the brains to avoid steels with high DBTT, plus the coldest I’ve seen the UK where I’ve been has been -17, and my primary worry was brake freeze and freehub pawl freeze, and neither was a problem.

andylFree MemberPosted 11 years agotoys19 – Member

well pretty much the only fcc steels are stainless.

bcc are all carbon steels apart from some of the mega high strength ones which are BCT, I can’t remember if the BCT ones are any good at low temps or not, semi pissed now…

It is hard to find a modern carbon steel that has not had its DBTT depressed significantly.

The best book on steels is Steels, Metallurgy and Applications by DT Llewellyn.

Or look in the ASTM series, I have lots of stuff on PDF/ereader that might be helpful.

Other than that here is a quick google.

https://www.google.co.uk/search?q=ductile+to+brittle+transition&ie=utf-8&oe=utf-8&aq=t&rls=org.mozilla:en-GB:official&client=firefox-a

http://www.exo.net/~jillj/activities/mechanical.pdf

http://en.wikipedia.org/wiki/Ductility#Ductile.E2.80.93brittle_transition_temperature

http://materialiaindica.ning.com/forum/topics/ductile-brittle-transition

https://www.google.co.uk/search?q=liberty+ships+failures&ie=utf-8&oe=utf-8&aq=t&rls=org.mozilla:en-GB:official&client=firefox-a

http://en.wikipedia.org/wiki/Liberty_ship#Problems

http://en.wikipedia.org/wiki/Ductile-brittle_transition_temperature#Ductile-brittle_transition_temperature

https://www.google.co.uk/search?q=materials+for+cryogenics&ie=utf-8&oe=utf-8&aq=t&rls=org.mozilla:en-GB:official&client=firefox-a

http://www.journalamme.org/papers_amme03/1240.pdf

http://www.google.co.uk/url?sa=t&rct=j&q=&esrc=s&source=web&cd=8&cad=rja&ved=0CHoQFjAH&url=http%3A%2F%2Fwww.springer.com%2Fcda%2Fcontent%2Fdocument%2Fcda_downloaddocument%2F9781441999788-c1.pdf%3FSGWID%3D0-0-45-1326037-p174117366&ei=SPr6UJuKDMil0AXI5YDwDA&usg=AFQjCNGMQIYKUe0dFWRW4PeKa9Be7xbzZw&bvm=bv.41248874,d.d2k

http://www.slac.stanford.edu/cgi-wrap/getdoc/slac-tn-03-023.pdf

http://cryogenics.nist.gov/MPropsMAY/5083%20Aluminum/5083Aluminum_rev.htm

http://cryogenics.nist.gov/Papers/Cryo_Materials.pdfA good explanation of Unit cells (which is what FCC and BCC refers to) is here and on wikipedia here.

Now that’s the kind of post that gets me excited.

I really want to improve my metallurgy so some reading for me there. 🙂

chief9000Free MemberPosted 11 years agoQuestion for you Toys19

You mentioned:

[In fact some aluminium alloys actually get more ductile at low temps. (6061 T6 for example) I can explain that if anyone wants to know about slip planes and arrhenius equations.]

Maybe you could shed some light on how this works? I would not expect any metals to become more ductile with reduced temperature. This seems very odd, of course I would expect ductility to increase with temperature as they progress towards melting point.But certainly not the other way round. Would be interested to hear why?

Cheers

toys19Free MemberPosted 11 years agobu66er, wish I had not said that.

How much do you know about crystal structure?

Do face centred cubic and body centered cubic (FCC and BCC) unit cells mean anything to you?Brain dump:I’m going to make some simplifications and generalisations now.

Deformation in metals happens in two ways, elastic and plastic.

Elastic: You can think of elastic as just springs stretching/compressing, which is the “bonds” between the atoms stretching, or squishing.

Plastic: is permanent deformation, so (simplified) when the “bonds” get stretched too far, they “break” and the atoms start to move relative to each other.

This movement manifests itself as something called slip, or dislocation movement, think of it like a ruck in a carpet.

Now these dislocations move along planes in the crystal structure, and the number of available planes depends on the crystal structure.In FCC there are 12 planes (called slip systems)which the slip can occur along easily.

In BCC there are none, well there are 12 but it is not a truely “close packed” system so it needs some heat to help the dislocations “jump” from one plane to the next.

See wikipedia here

So that explains why FCC metals stay ductile at low temps, and BCC metals do not.

Next is why the ductility of FCC metals can “increase” at lower temps.

This is a bit harder to explain as it relates to competing processes that are thermally activated.

In all metals at higher temps the ductility increases. Purely due to available thermal energy making the atoms “looser” in their lattice so dislocations can move more easily. But this does not happen until higher temps have been reached (remember competing process).

Another process that happens with temperature is vacancy generation and diffusion in the crystal lattice. What this means is that some atoms jump out of position and leave a hole, this is a vacancy, and it causes a high energy lattice strain (an incongruence) due to the imbalance of the attractive/repulsive forces of the atoms no longer being ordered. The jumped atom squeezes in elsewhere (called an interstitial) and has a similar strain effect. These lattice strains can slow down dislocation movement and hence make the material less ductile.

BTW Spontaneous vacancy generation is modelled by an arrhenius equation which is exponential with temperature. (There is also some interesting stuff in semiconductors that is related to this, but I won’t go in to that now) The vacancy generation is limitied by an activation energy which is required to kick start it.

So thermal lattice vibrations increase ductility, but vacancy and interstitial generation can decrease ductility. These processes compete.

As temperatures decrease so do the generation of vacancies/interstitals, which in FCC metals means that disclocations can move about more freely without bumping into holes/vacancies.

But in BCC as temps decrease, there is no thermal energy to activate slip onto other planes, so ductility decreases.

So competing processes: with 6061 (an FCC metal) if you cool from say 200c, then ductility decreases as thermal mobilty decreases, until around 0c then ductility starts to increase (slowly) as the vacancy/interstitial generation tails off. I can’t quite remember but I think this is around the temp of the activation energy, below which there is no vacancy generation. (room temp is considered warm/high energy in these terms)

I’ll bet you wish you hadn’t asked now…

(Caveat: All simplified and generalized, so if you are a metallurgist too, please do not shoot me down, I’m sensitive..)

The topic ‘Frame failures – At which low temperature do you not risk riding your mtb?’ is closed to new replies.