- This topic has 18 replies, 9 voices, and was last updated 6 years ago by kraken2345.

-

Bearing Removal Advice Needed

-

kraken2345Free MemberPosted 6 years ago

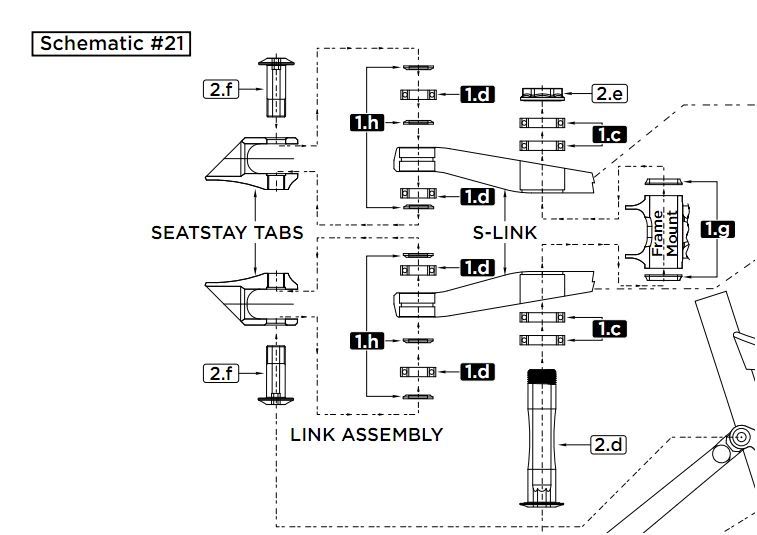

So I’m changing the bearings on my Pitch and all have been easy using a blind bearing puller except the main pivot bearings attached to the seat tube. Rather than a spacer there’s 2 bearings back to back on either side. The problem with the simple method of using 2 different sized sockets is that the faces on the rocker link aren’t parallel so even using a threaded rod is proving very difficult without 4 hands and I’m unsure how to keep the 2 sockets even remotely parallel. The bearings are labelled 1c in the schematic.

Cheers

DiscJockeyFree MemberPosted 6 years agoI don’t know that frame, but will have a go at suggesting something.

Once 2.d is removed, can you move the swing-arm away from the seat-tube and access the inner faces ? If so, are those faces parallel ? If so, can you not push the bearings outwards, or is there not a large enough hole to fit a driver/socket onto the bearing inner race?

argooseFree MemberPosted 6 years agosuitable sized expanding rawl plug, tighten into bearing and tap out with nylon hammer or normal hammer on lump of hard plastic

kraken2345Free MemberPosted 6 years agoThe inner faces are parallel with the frame, the outers that you’d usually put a larger socket against for the bearings to fall into are at an angle as shown. I’ve tried using a socket and whilst it has no problem fitting against the inner race of the innermost bearings, thus far it’s proven problematic to overcome the resistance that the 2 bearings are providing as they oppose motion.

I was just wondering if hit it harder was the correct way to go or if there was a method for dealing with such things I was unaware of. Trying to find a way to support the rocket more evenly if it does come to hitting it harder but many things will only mark it.

noahhowesFree MemberPosted 6 years agoI did one of these a while ago. I’m pretty sure some gentle tapping with an old small screwdriver between the two bearings got them out. If you don’t want to tap them all the way out you could just create enough gap to get a blind puller in there. Not ideal, but then it’s a tricky lot to get out and it solved the problem.

kraken2345Free MemberPosted 6 years agoThat seems like a decent thing to try, I did think about creating a gap but didn’t think there’d be room. That rawl plug method can be my backup, cheers

survivorFull MemberPosted 6 years agoThose little bastards!

Bain of my pitch owning life those were!

I never had problems getting them out with a blind bearing puller but getting them back in again was another matter.

I’ve no real advice other than take your time don’t rush be prepared to damage/mark the rocker and bearings to go in wonky. It may help if you have someone else to hold the link for you while you try and tap the bearings back into place as due to its shape it won’t hold in a vice.

Best of luck 🙂

kraken2345Free MemberPosted 6 years agoMaybe I just wasn’t pulling hard enough with the bearing puller. I’ll try clamping it in some soft jaws tomorrow, just seems like 2 bearings to remove at once will require a crap tonne of force.

survivorFull MemberPosted 6 years agoMy bearing puller could do one at a time. Just insert the appropriate sized collet and tighten up just behind the first bearing. The bearings have a slight chamfer on so it’ll grip once tightened up. I just held the link and dropped the slide hammer down rather than using a vice.

It is possible if the bearings are stuck that you’ll pull the middle of the bearing out leaving the outer race in. If that happens just us a bigger collet to remove it. Again, tighten it up enough and it’ll grip.

kraken2345Free MemberPosted 6 years agoThis is my first time using a slide hammer. Did you just hold both ends of the rocker and drop the weight or did you hold it with one hand and throw the weight down in your hand?

survivorFull MemberPosted 6 years agoJust held the rocker in one hand and repeatedly and furiously smashed away with the slide hammer 🙂

Don’t be scared you’ll need to be rough with if it was like mine.

As I said it’s the getting the new ones back in that’s the problem. Try your best not to let them go in wonky or they’ll score the surface

kraken2345Free MemberPosted 6 years agoI think because my bearing pullers were quite cheap they don’t seem to have any real edge on the end to dig into that tiny dip between the 2 so tomorrow I’ll try filing them into a sharper edge to try to get it in there

angeldustFree MemberPosted 6 years agoJust done mine on a stumpjumper. The frame bearings were the easiest to remove by far. Just knocked them out gently with a hammer and small chisel. Used the rrp bearing tool for the rest, except the double blind seat stay bearings where I used a double blind puller.

kraken2345Free MemberPosted 6 years agoWhat did you support the parts with whilst using the hammer and chisel? Hesitant to hold them in a vice and just lying them down means they bounce around when hit

vincienupFree MemberPosted 6 years agoI had a similar issue with a Zesty.

I tried to soldier on and crimped the swingarm so it was impossible to refit and didn’t fancy bending it back out as aluminium isn’t known for its property of retaining strength when bent and rebent. Fortunately I had a part stripped old Spicy frame so pinched the swingarm.

Try a packing piece such as 15mm poly pipe cut to appropriate length before you start applying loads?

mrjmtFree MemberPosted 6 years agoKind of pinching the idea from previous post but can’t you cut a piece of plastic piping (of the correct diameter) to match the angle of the swing arm instead of using a socket?

finishthatFree MemberPosted 6 years ago1st put the bearing puller in place and tension it , a piece of wood/pipe to

help with the angle.

Then Heat the rocker by slowly pouring kettle of boiling water over it – or if you have one use a heat gun on low and keep it moving to stop the paint being attacked.

Then without delay pull the bearing .

Heat helpskraken2345Free MemberPosted 6 years agoThey shifted! Admittedly not very gracefully however after trying for the best part of 3 days I lost my patience, found a large rubber o-ring used on one of our annealing furnaces, heated the rocker and whacked it out with an impact socket and copper mallet whilst supporting it with the rubber. It’s got a little marking on the inside now but my problem has been being too careful and the bearings were old as hell so were pretty firmly seated. It’s only lost a little anodizing anyway.

Thanks all for the advice, next week I shall attempt the install of the new uns which should be much more straightforward.

The topic ‘Bearing Removal Advice Needed’ is closed to new replies.