- This topic has 25 replies, 18 voices, and was last updated 10 years ago by Kahurangi.

-

3D scanning and rapid prototyping services

-

ir_banditoFree MemberPosted 10 years ago

I’d like an aluminum version of a small plastic bike part made up. Easiest way has got to be to get a 3D scan of it, and then either 3D printed, or machined.

Anyone know of a cheap but good quality service?I guess the cheapest option is to measure it and produce a 3D cad/2D drawing of it and get a local machine shop to knock it up, or even have a go myself on my little hand-mill. But I’m curious about the price of the fully automated method.

porter_jamieFull MemberPosted 10 years agoit’s probably not the easiest way, you scan it then someone has to make sense of the point cloud and turn it into a model. and getting it 3d printed in metal isnt going to be cheap.

email me a drawing and i’ll give you a quote for machining it.

ir_banditoFree MemberPosted 10 years agoI’ve not got a drawing of it yet, but I will do when its done.

Thanks.ahwilesFree MemberPosted 10 years agowhat he ^ said.

a photo wouldn’t hurt?

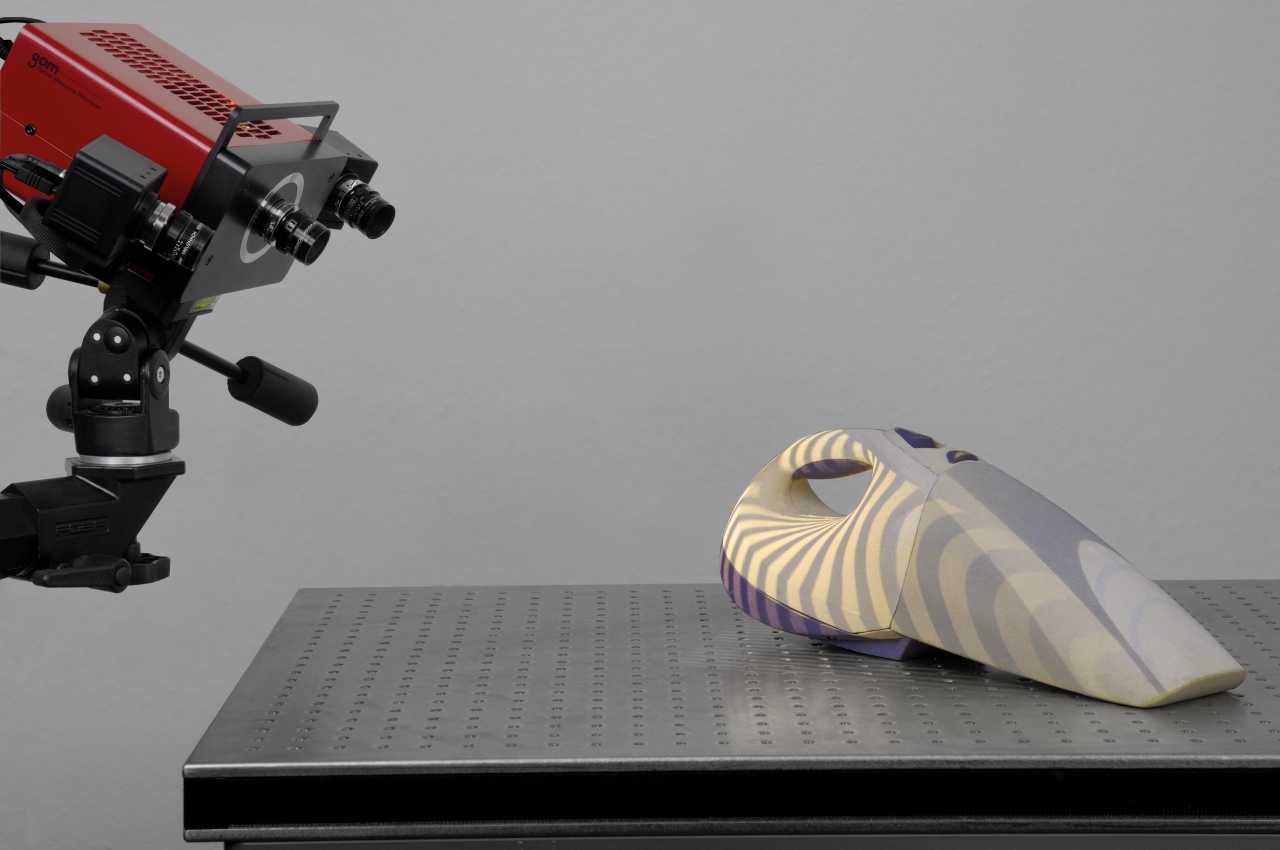

it would take me a day or so to scan a small part – using a GOM Atos scanner.

that’s about £500.

then a few days to convert the result (an STL file) into a IGES file, i would charge something like £1000

(an uninspiring, but necessary step if you want to use the scan as a base to drive the CNC moves from.)

i have no idea how long it would take the CAD-CAM guys to program the CNC machine, people always assume my job is easy, so i’ll return the favour and suggest 1 week, and call that £2000.

and then you’re (sort of)ready to make millions of them.

for an extra £50,000 we will optimise the process, reducing the cycle time by around 50%.

winston_dogFree MemberPosted 10 years agoHave you tried here? I bet it’s not cheap though!

They are also in the US.

jackthedogFree MemberPosted 10 years agoI know of a 3D scan and print company in Sheffield, but it’s not really a service provided to the engineering industry; more computer game stuff.

I’ve never had anything to do with that kind of work, but I suspect from the little I know that by the time you’d cleaned up the mesh it spits out sufficient to machine from, you might as well have built it from scratch.

woody74Full MemberPosted 10 years agoPut a request on people per hour and find someone that can model it. If it is a simple shape then it can be quite cheap. Drop me an email and I can pass on the contact details of a guy we use for this type of thing.

Getting it made is really the big hurdle and probably wont be cheap as it is in metal. If it was in plastic or really small metal then Shapeways is good. You could also try http://www.firstcut.com

Th other option would be to farm it out to China as that would be really cheap. Do a search on Alibaba for CNC or rapid prototyping and you will get a whole list of people. If it is a simple shape then a engineering shop here way do it cheaply by hand and not CNC.

nickjbFree MemberPosted 10 years agoI do this sort of thing as part of my day job. The hype of 3d scanning doesn’t quite match the reality. We aren’t quite at the stage where you pop your prototype in a drawer and out pops a dozen copies. Drawing it makes more sense as you can tweak the design for manufacture and have an easy to edit model for any future work.

richmarsFull MemberPosted 10 years agoI’ve used First Cut, link above and also Arrk. Cost depends on how quick you need it (assuming it can be made etc). A lot easier if you can produce a 2D drawing to give to a local machine shop, or STL for first cut/Arrk.

If you need lots, Arrk have resources in China, but that doesn’t always mean it will be cheap.takisawa2Full MemberPosted 10 years agoModel it up & send it to Arrk.

Then sit down when you open the quote. 😀Arrk are good. I’ve used them plenty of times.

Had their sales guy in a few weeks ago in fact.ir_banditoFree MemberPosted 10 years agowhat is it anyway?

the thumb lever bit of one of these:

Mine snapped, and I’m getting a new one under warranty. Looking at the size and shape of it, I think the replacement will probably snap too, so I want to get a metal one made up. As soon as the new one gets here, I’ll measure it and model it up.

As for the actual 3d-scan data, in a past job I used the cloud data from a scanned gorilla’s head to make up the internal shape of a mould tool used for promotional giant gorilla’s head for the King Kong movie. Don’t have access to the software any more though.

DaffyFull MemberPosted 10 years ago3D printing of Aluminium isn’t the easiest thing either. Steel/Ti etc are all easier to deal with.

SpeederFull MemberPosted 10 years agoDoes anyone still use a copy mill? Could be a viable alternative if it’s not too complicated and you can find someone with a machine.

What’s the part anyway? I’m guessing something that’s broken that you want made out of something less breakable. . .

spandex_bobFull MemberPosted 10 years agoLooks pretty easy to model; I’ve never used google sketch up but have heard good things. That could give you a cheap (free) 3D model, then drawing, then local machine shop. Possible route to a one-off part without machining is to 3D print the model as a wax (you’re looking for a thermojet machine) then get it investment cast in metal of choice, or whatever happens to be being cast on the day. Will then need post-cast machining for pivots / bushings etc. Beefing it up could of course mean breaking something more fundamental inside if you have another stack.

richmarsFull MemberPosted 10 years agoLooks like you could make that (or something that would work) in carbon.

IanMunroFree MemberPosted 10 years agoI reckon a carbon reinforced tea spoon would be a good starting point.

ir_banditoFree MemberPosted 10 years agothanks for all the advice. Basically i was trying to find out of the the ability to “copy and paste” exists, in a cheap and easy process. It seems it doesn’t (yet)

3D modelling isn’t an issue, I use Pro/E at work (I used to teach people how to use it) and I’ve got Inventor at home.

There are a few local machine shops I can get quotes from (as well as Jamie Porter), or I can make it myself using my own benchtop milling machine if I make up a jig so I can get the arc-shaped cable groove in it.Hadn’t thought about the carbon option. I’ve a mate with an autoclave who build bodies for recumbent bikes. Hmm…

richmarsFull MemberPosted 10 years agoI’d use the part to make a mould, then a simple wet lay up with a vauccum pump. Simple. What’s going on inside? Is the a pivot/bearing? You may need to embed a metal sleeve in the carbon.

Don’t need an autoclave, but you can put it in your oven for a post cure bake, which helps.cr500domFree MemberPosted 10 years agoI could probably measure that manually, and model it in less time than it would take to scan and post process the data.

You could simplify it a lot for machining too

cr500domFree MemberPosted 10 years agoAs a recommendation for CNC small batch stuff or initial prototypes, where the Programming cost is the biggie.

I have often had good quotes and very good quality finished components from a company called FRP.

They basically send it out to a huge number of CNC jobbing shops out in the far east.

Sometimes (If there is spare capacity) they can be very cheap

And this was when we had our own Machine shop, FRP could do the job cheaper than we could program it…..

But close to home then Porter-Jamie is your man 8)porter_jamieFull MemberPosted 10 years agohave you got the old broken one? if it’s just the thumb lever it shouldn’t be too tricky

5thElefantFree MemberPosted 10 years agoIf you just want one the quickest and cheapest way would involve a lump of aluminium, a hacksaw, a drill and some files. It’ll take an afternoon.

KahurangiFull MemberPosted 10 years agoLast night I was looking at the University of Canterbury’s 3D scanning and 3D printing kit. Their scanning set-up gave them a 3D model, which then needed processing and manual intervention to produce a model which could be measured let alone given feature definitions and edited. It would give you something to compare to your generated 3D model though.

Worth getting in touch with local universities to see if they’d let you have a play with their stuff 🙂

The topic ‘3D scanning and rapid prototyping services’ is closed to new replies.